As manufacturing becomes global business and more complex, integrating with customers and connecting cross-regional operations, becomes increasingly difficult to manage from on-premises. Manufacturers need a centralized production management system that can be accessible beyond boundaries. This is why matured manufacturers are adopting cloud MES (Manufacturing Execution Systems) to keep all their operations running more efficiently. Cloud MES solutions are gaining adoption in the manufacturing industries in recent years due to lower investment, faster ROI, and better accessibility.

What is Cloud MES?

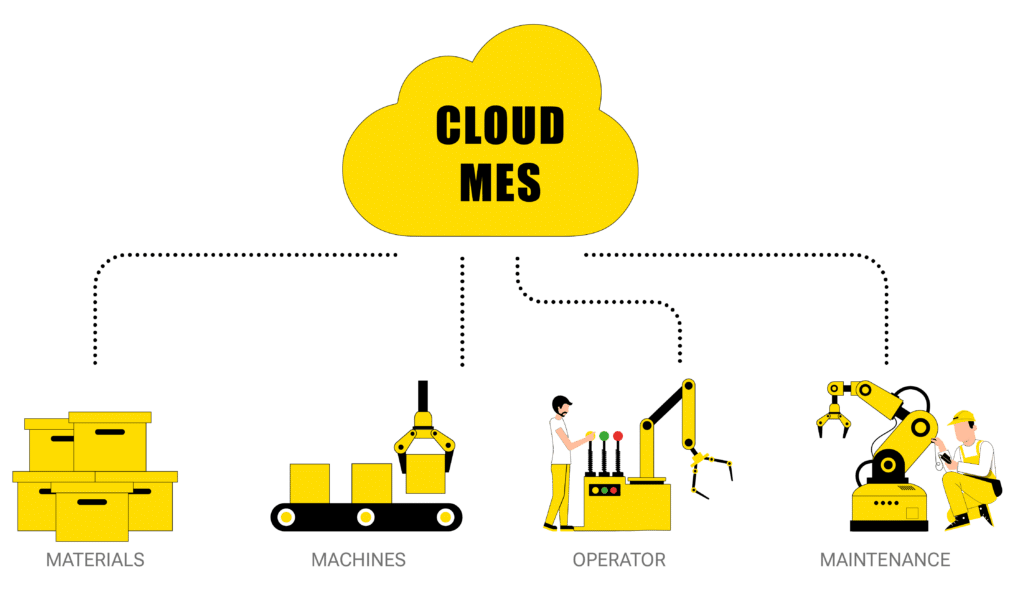

The cloud MES (Manufacturing Execution System) solution implies the entire application and its functionality, data storage, data processing, and data backup are entirely available on the cloud as a centralized system. Cloud MES solutions connect the shop floor to your overall business systems for wider visibility across all your plants. Manufacturers are currently leveraging this technology to optimize operation by integrating production processes with their larger ecosystem of management and suppliers to:

- Serve their customers more efficiently.

- Incorporate the capabilities of digitization.

- Adapt to the market by establishing a high-value process, and smart assets.

The introduction of cloud computing enabled this integrated manufacturing software-as-a-service (SaaS) platform that addresses all the needs of manufacturers. Cloud-MES provides insights into execution, quality, production, plant maintenance notifications, and ERP integration. Smart factory integration with a Cloud MES system enables seamless production execution based on end-to-end visibility supported by advanced manufacturing analytics. Modern Cloud MES solution inherently integrated with machines through IoT, quality control processes, ERP / MRP and other Cloud Apps.

Cloud MES is a centralized business system for modern manufacturing operations, which helps all factory users to connect, collaborate and and execute production operations seamlessly.

Why Cloud MES is critical for Manufacturing?

The purpose of cloud MES software is to streamline, modularize, and execute manufacturing orders in real-time. Cloud MES focuses on multiple functional areas such as management of product life cycle, scheduling of resources, order execution, production analysis, monitoring of overall equipment effectiveness, etc. Although these systems are primarily used for operating as standalone systems, they are also increasingly being integrated with ERP (enterprise resource planning) and MES systems that help to improve productivity and reduce the total manufacturing cycle time. The technology advancement in Cloud MES helps to take advantage of the connected data and integrate them quickly.

Cloud MES Vs On-premises MES:

Prior to the Cloud era, Industries were widely using on-premises ERP / MRP system for manufacturing operations. However, ERP/MRP does not provide the necessary features to run factory floor operations digitally. MES provides unique features for production planning and tracking work executions to have better control on the shop floor. Due to the nature of physical needs on the shop floor, MES was implemented as software.

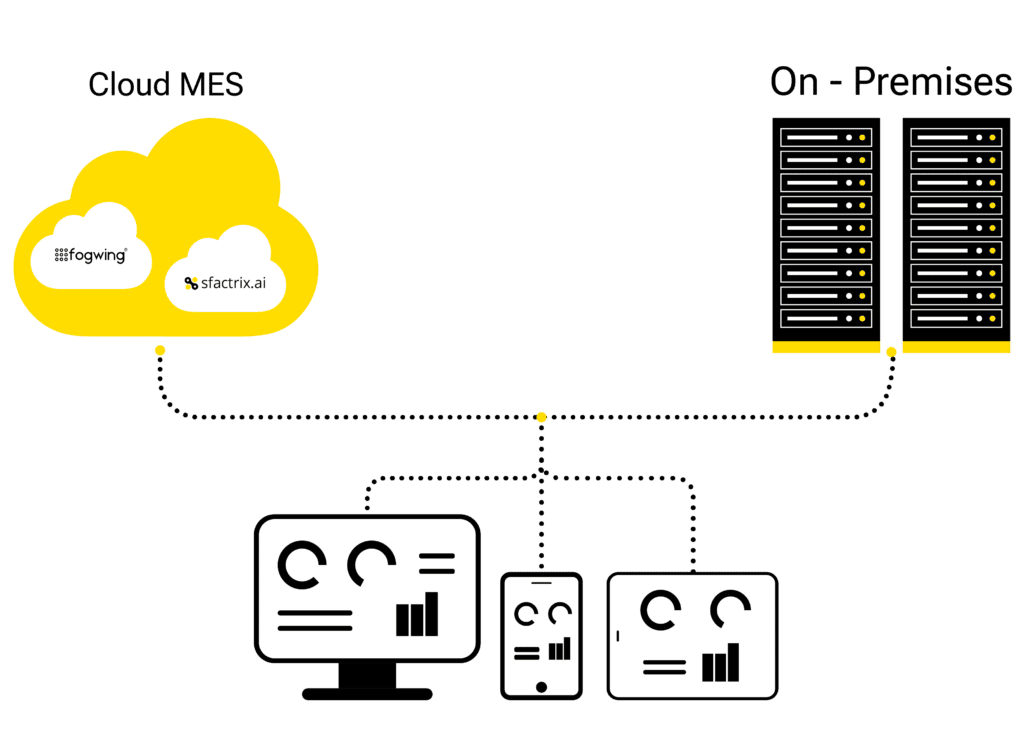

The on-premises MES sets the necessary equipment and devices on the operation site, while the cloud-based MES sets supporting equipment onsite but consolidate the data and analysis on the cloud to give higher visibility.

On-premises MES was assumed as more secure within an enterprise firewall but also prevent the data visibility for global operations. Cloud MES provides centralized data management and also high data security through advanced Industrial Cloud infrastructure.

Benefits of Cloud MES over On-premises MES

With the advancement of cloud computing technology in recent years, most manufacturers are turning to cloud MES solutions that help centralize the manufacturing operations by connecting all factory floor functions more effectively. Cloud MES native support of centralized data storage and visualization helps to monitor and optimize various operations, at each step of production, and coordinate all processes in real-time from anywhere.

Below are a few benefits of Cloud MES over On-premises MES solutions:

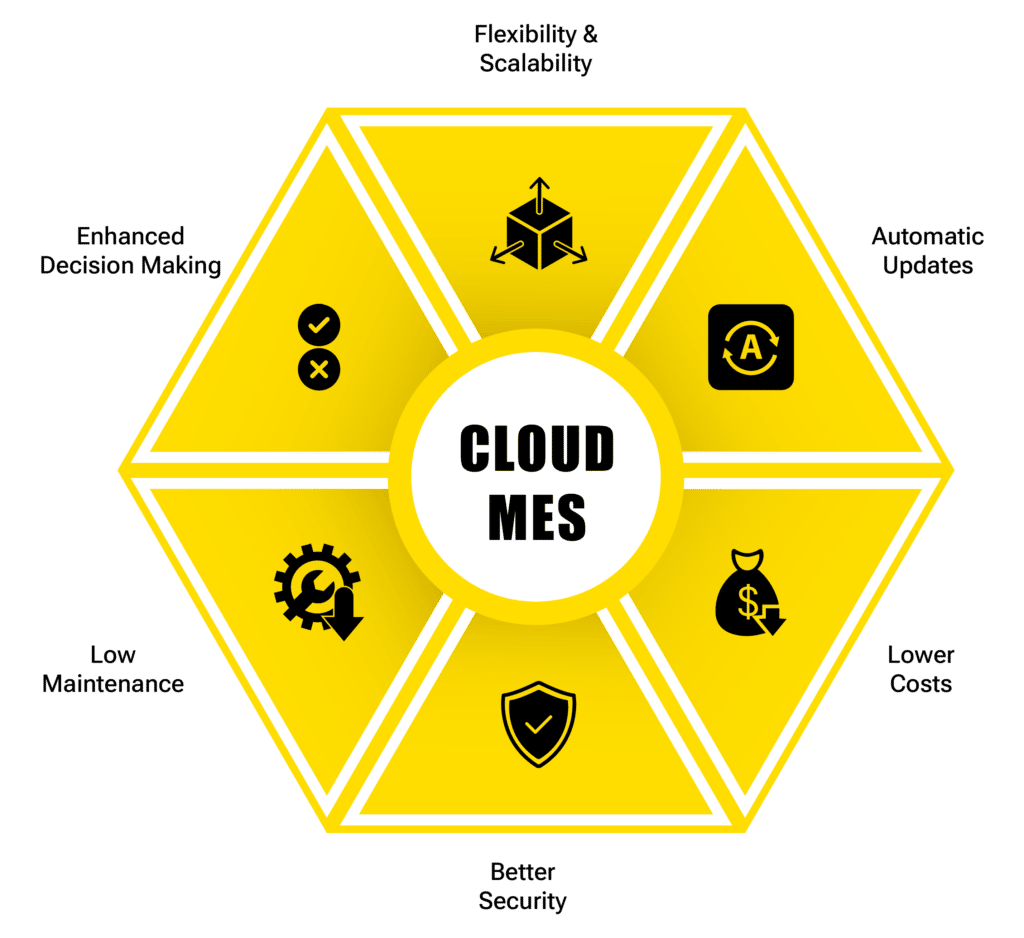

Flexibility and Scalability:

A digitalized manufacturing plant produces large-scale data that needs to be stored and processed for better business analysis. A Cloud MES solves the problem of data storage and processing without investing heavily in the infrastructure. Cloud hosted MES is scalable faster with cloud native auto-scaling infrastructure and less downtime to meet high availability requirements.

Automatic Software Updates:

Cloud MES providers are offering MES as Software as a Service which is being continuously updated through continuous improvement releases with no downtime, easy application administration, monitoring, and back-ups services.

Lower Investment:

The on-premises MES requires a large capital investment to deploy the necessary hardware infrastructure and implementation cost. It also requires 50% of the capital investment as OPEX to manage the infrastructure for high availability. While cloud MES software requires low capital investment due to the subscription or pay-for-your-service model offered by the solution providers. This helps manufacturers to save huge CAPEX and OPEX in adopting modern MES solution.

Higher Security:

On-premises MES requires security experts to manage the growing security challenges, while for cloud-based MES providers offer inbuilt data and access level security to secure the application end-to-end. The advanced DDoS (distributed denial-of-service) and AES (Advanced Encryption Standard) security offered by cloud services add more strength to protect the business data and promise better comfort.

Lower Maintenance:

On-premises MES requires ongoing IT resource efforts such as daily backup and restore, user support, disaster recovery exercise, release upgrades and data center infrastructure management capabilities (cooling system, power backup, and access control). With Cloud MES, Enterprise IT resources and costs can be saved significantly as the cloud service provider manages MES maintenance and updates.

Faster Decision Making:

Cloud MES provides real-time access to factory performance data, leads to informed decision-making, allowing companies to be more responsive to market demand needs or changing consumer preferences. Deploying cloud MES programs will quickly optimize real-time decision-making across multiple facilities.

Cloud MES Solution Demands

As per IoT Analytics’ latest report, ‘’the cloud penetration of Manufacturing Execution Systems is to increase, with cloud MES forecasted to become a $2.34 billion market in 2026’’. Manufacturers are adopting MES Cloud solutions as it allows them to take advantage of the latest technologies and offers better scalability than on-premises MES systems.

One of the main reasons for the growing adoption of MES Cloud solutions is the desire of global manufacturers to improve their businesses and operations through more integrated systems that provide connected information or data and offer complete transparency and control in operations. The increase in manufacturing activities for mass production and quality improvement is driving the need for Manufacturing Execution Systems Cloud.

The growing demand of Cloud MES for process manufacturing is evident across industries like aerospace, metals, plastics, electronics, pharmaceuticals, and more.

SFactrix – The Smart MES on Fogwing Industrial Cloud

SFactrix is a Cloud Smart Manufacturing Execution System helps manufacturers to digitalize production execution and automate factory floor operations. It’s a user-friendly manufacturing software solution to enable quick configuration of the plant organization setup. SFactrix Smart MES solution requires no technical skill to operate, no download or installation. It comes with an in-built AI-based manufacturing execution system that serves small and medium businesses (SMEs) with a complete smart factory solution. SFactrix is powered by Fogwing Industrial Cloud, so it is naturally supports machine integration through IoT connectivity, which helps in production automation.

SFactrix is an ideal choice for any manufacturing companies looking for production optimization solution through cloud MES.

To know more about SFactrix Smart MES, visit Smart MES Software.

Conclusion:

Having analyzed both on-premises and cloud Manufacturing Execution Systems, it can be concluded that a cloud-based MES holds an edge over the on-premises MES. This can be attributed to the fact that cloud-based services are improving and evolving rapidly by integrating other relevant technologies like IoT. Whether manufacturers are looking to streamline their operations or simply develop a single source of truth that every department can draw upon, an MES tool on cloud is a safe bet for its countless use cases.

The Cloud MES provides more scalable, faster, and easier functionalities. Hence, manufacturers are adopting cloud MES to achieve Industry 4.0 smart factory solutions.