Maintenance and reliability are closely related disciplines that determine how effectively an organization can keep its assets performing at peak levels. The maintenance management focuses on the maintenance inspection, reactive,

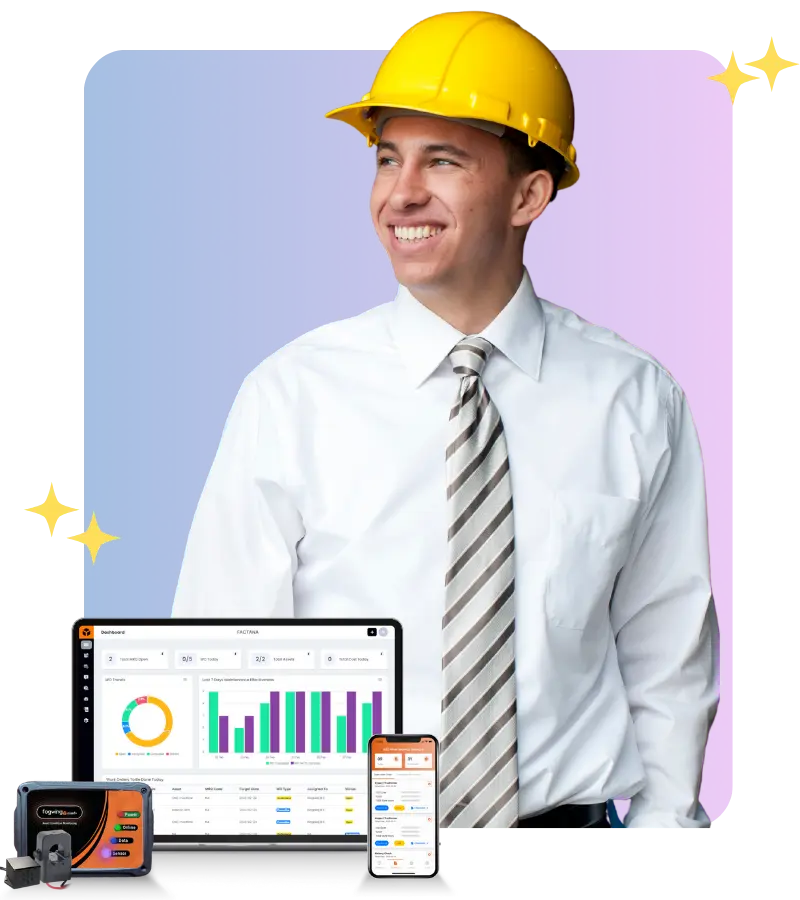

Read More#1 CMMS, EAM and QMS Software for Smart Manufacturing

Gain Excellence with an AI-Powered Smart Manufacturing Platform.

Fogwing Platform offers a comprehensive CMMS, EAM, APM, and QMS software solution for smart industrial operations. Powered by Industrial AI and IoT, Fogwing streamlines asset management, equipment maintenance, productivity, and quality control, enabling operational excellence.

Over 10,000+ Industrial Operators trust Fogwing for Productivity

Redefine Your Growth with Fogwing

Discover the power of Digital Manufacturing – Fogwing Industrial Software Suites revolutionizes your asset operations, optimizes efficiency, and unlocks unprecedented productivity. Streamline processes, monitor real-time data, and drive informed decision-making.

Fogwing Powering Smart Manufacturing with Intelligence.

Fogwing CMMS Software for Maintenance Team

Maximize Asset Reliability and Maintenance Operations.

Fogwing CMMS Software offers an all-in-one asset reliability management solution, combining Smart CMMS and Asset Management for efficient maintenance operations. Leverage the power of IIoT and Generative AI for digital maintenance operations. Elevate your asset reliability and decrease maintenance operational cost.

Fogwing Matrix for the Production Team

Optimize Production with Productivity Monitoring Software

Unleash your manufacturing potential with Fogwing’s Smart Operations Software. Elevate productivity, streamline resource allocation, and optimize operations using our cutting-edge system. Gain real-time insights into utilization, OEE, and proactively plan and execute. Fogwing’s Operational Software empowers you to attain superior operational excellence and fuel business growth.

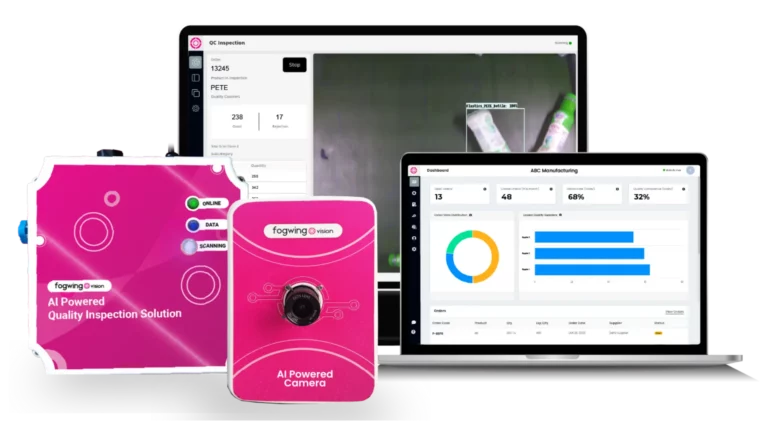

Computer Vision for Quality Team

Automate Quality Inspection with AI-Powered Machine Vision Software.

Fogwing Vision enhances quality control operations with AI-powered machine vision software that automates quality inspection with precision and speed. Fogwing helps to detect defects, ensure consistency in quality, and reduce errors in manual operations. Fogwing helps to achieve higher efficiency, lower production waste, and superior product quality of delivery with real-time visual inspection.

Our Software Suites for Smart Manufacturing

Minimize Downtime; Maximize Efficiency.

Fogwing for Smart Manufacturing.

Fogwing offers Smart Manufacturing solutions that give software tools and insights so every manufacturing operator can run operations efficiently and effectively.

Enterprise Asset Management

Digitize asset info, category, associations, and reliability to optimize performance for efficient operations.

Smart CMMS

Simplifies work order management, task assignment, tracking, and completion for enhanced efficiency and productivity.

Asset Performance Management

Automates preventive maintenance tasks, scheduling, and assigning to prevent downtime and optimize performance.

Productivity Management

Get realtime visibility of production metrics, OEE, OOE, Cycletime, Throughput through machine monitoring.

Quality Inspection Management

Automate quality checks with computer vision for higher assurance, fewer human errors, and better delivery.

Workplace Safety Monitoring

Leverage environmental sensor technologies to monitor the shop floor environments and worker safety.

Industrial AI Copilot

Your Copilot for Smarter, Safer, and Faster Industrial Operations

Fogwing Copilot provides the industry-specific knowledge and expertise required for the operations team as a personal AI assistant. Our Industrial AI Copilot provides instant answers to technical questions, so your technicians can stop wasting time in exploration and focus on uptime.

Highly Rated by Industrial Community.

Powering Industries with Cutting-Edge Industrial Software.

Awards and Recognitions

Fogwing keeps your data safe

Prevent data loss or unauthorized access with our top-tier security measures, which encompass:

Instant Hot and Cold Backup

99.7% uptime guarantee

Hosted on Azure and AWS Cloud

SOC Type 2 compliance

ISO 27001:2023 Certified

Explore the Knowledge Hub

CMMS for Manufacturing: Best Practices & Insights

Manufacturing industries rely heavily on automation machinery and equipment for daily productivity. Any machine downtime during production will have a financial impact due to non-productive work hours, quality degradation, and

Read MoreBest CMMS Software Middle East – Top Solutions for 2025

Due to industrialization and infrastructure expansion in the Middle East, the region is experiencing fast growth in its oil & gas, construction, logistics, utilities, and manufacturing, enabling it to embrace

Read More