Best CMMS Software for Maintenance

Simplify Asset Maintenance & Operations with Fogwing CMMS Software

Fogwing CMMS Software is the easiest computerized maintenance management software for Maintenance and Reliability Managers. This software allows to execute maintenance operations with real-time insights for higher reliability and performance.

Over 10,000+ Manufacturing Operators trust Fogwing for Productive Day

AI-Powered CMMS Software for Preventive & Predictive Maintenance.

Fogwing CMMS Software represents cutting-edge smart maintenance management infused with the capabilities of IoT and AI technologies. With Fogwing, you’ll have all the tools necessary to streamline your maintenance operations, offering real-time insights that lead to enhanced operational efficiency and reduced costs.

CMMS Software for Seamless Maintenance Operations.

Stop manual maintenance operations. Embrace a digital solution for enhanced operational efficiency.

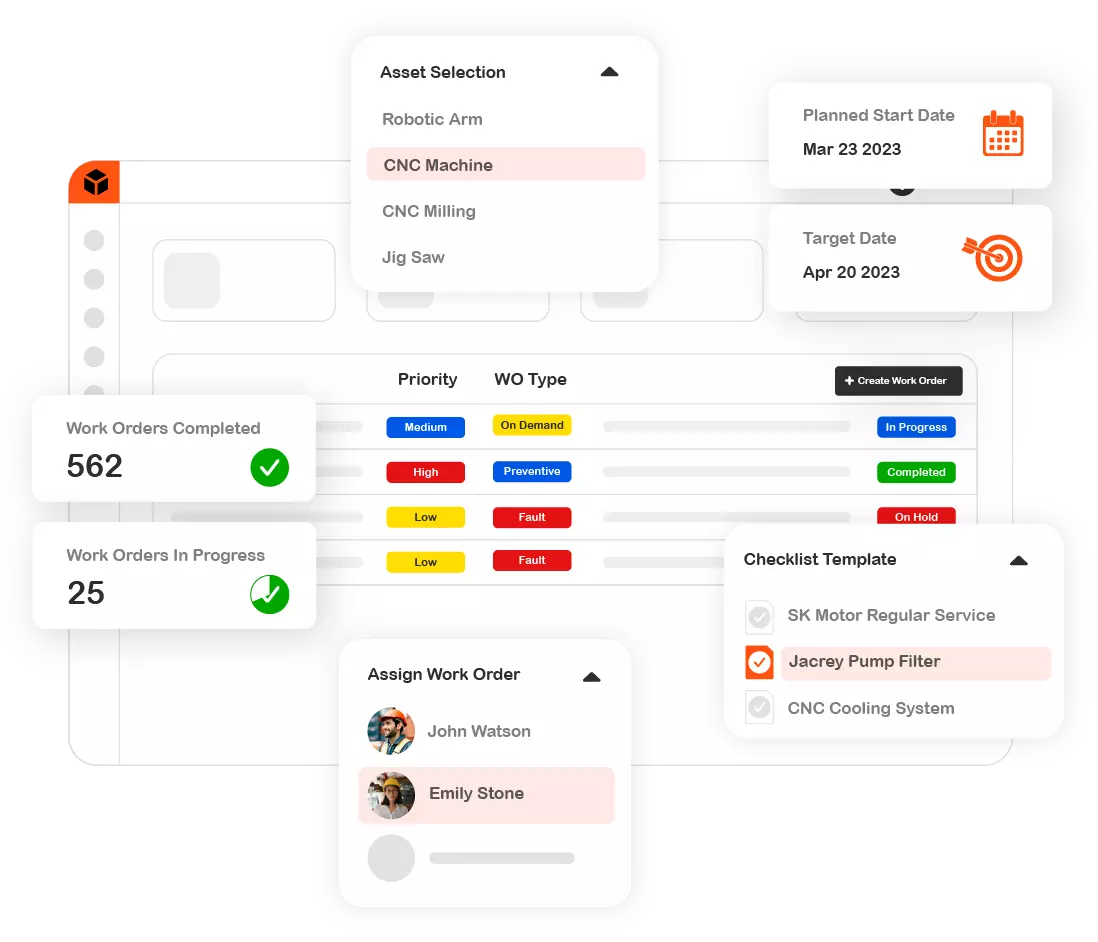

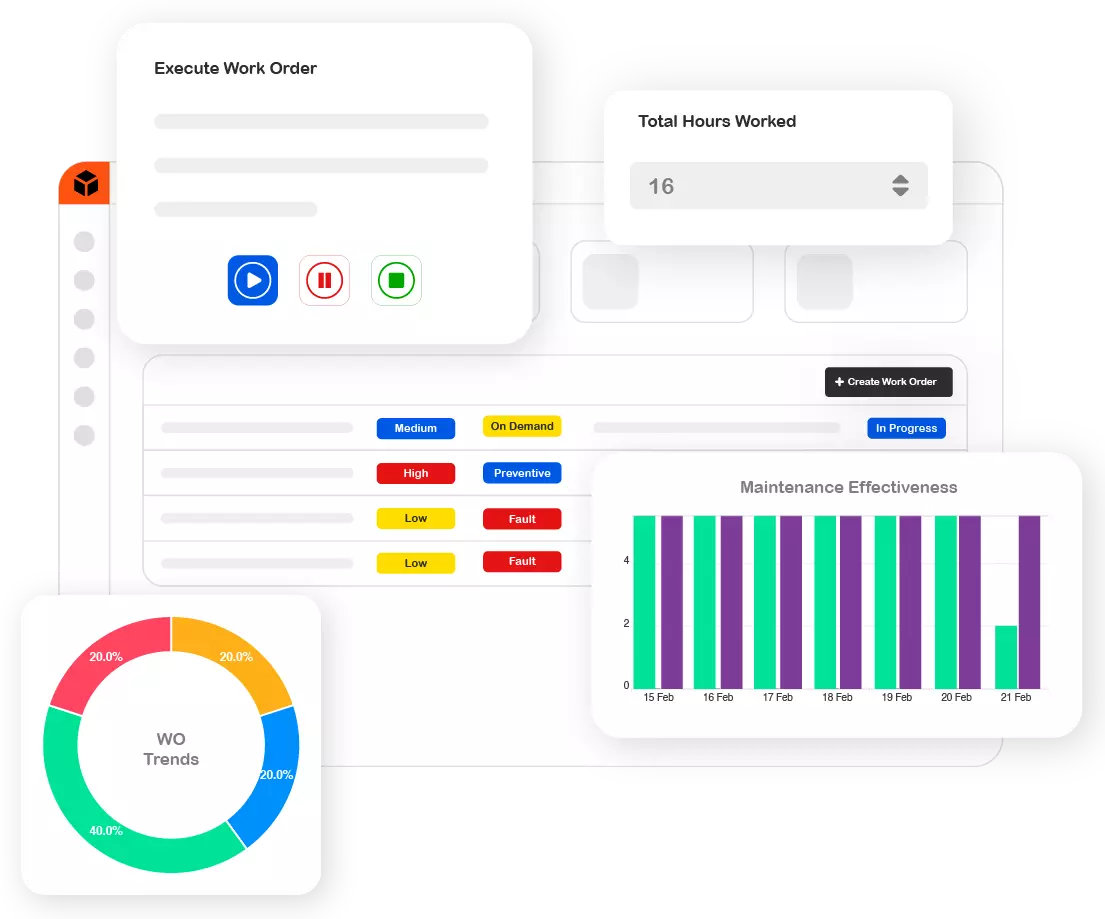

Digitalize Work Order Management

Tracking maintenance schedules, assignments, and completion manually is impractical. Utilize Fogwing CMMS Software to facilitate collaboration between Maintenance Managers and Field Engineers efficiently.

Fogwing CMMS allows to create, assign and execute unlimited work order for your entire team.

Schedule your maintenance works ahead by creating maintenance work orders and assign to field engineers proactively.

Allow your team plan their days ahead by accessing the assigned work orders, work schedules from anywhere.

Fogwing CMMS Software is also a tracking system to capture maintenance reports, hours, and metering from the field.

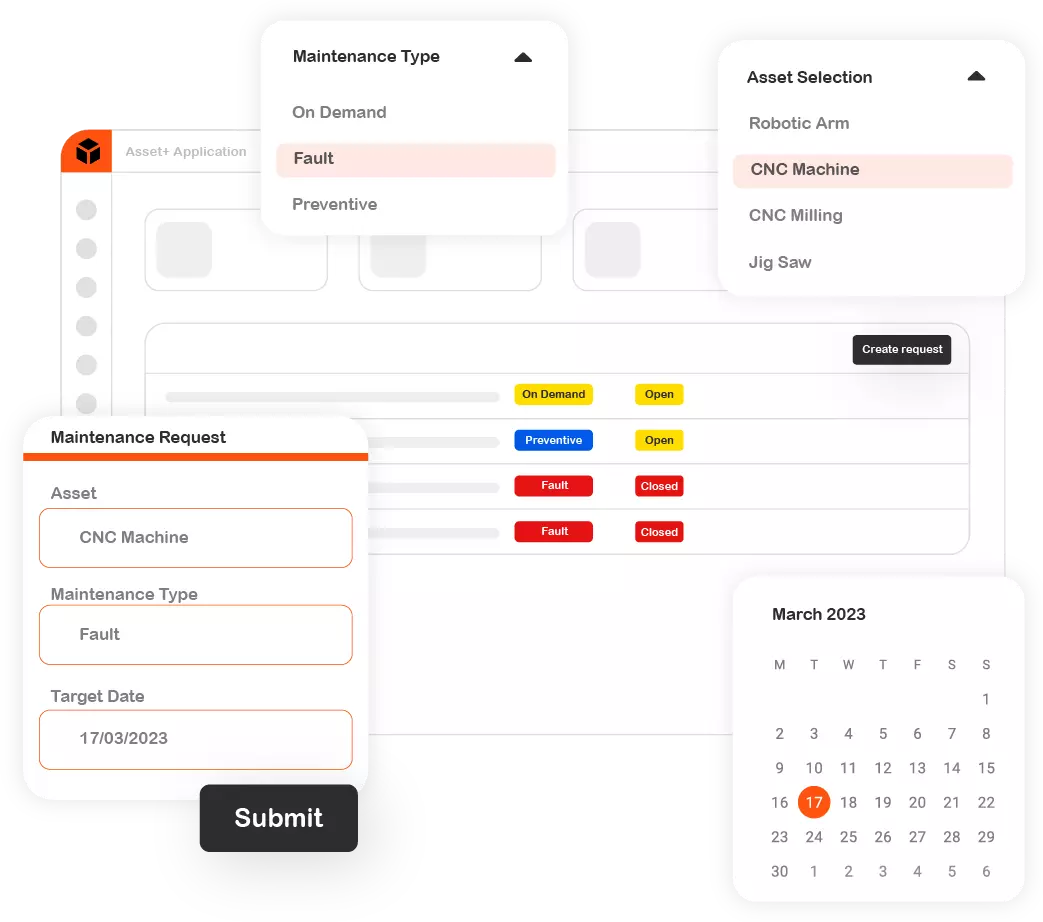

Optimize Maintenance Request and Approval

Provide access to internal and external customers to receive maintenance, repair or other request through portal. Automate generate work orders from maintenance request without any manual efforts.

Allow external and internal customers to raise request online

Get end to end traceability of maintenance efforts from maintenance request to work order completion

Provide visibility to all stakeholders on the maintenance effectiveness with MRO reports.

Excel of Asset Maintenance Operations

As your field engineering work on the maintenance orders, let them report the work status, findings and parts usage instantly through app. Get the overall progress and maintenance work effectiveness.

Field engineers can Start, Hold and Complete the work order assigned to them as they progress in the day.

Allows the field engineers to reserve parts required to complete the work order and report On-Hold due to other technical issues.

Once work order is completed, Engineers submit the work hours and final comments for Manager's review.

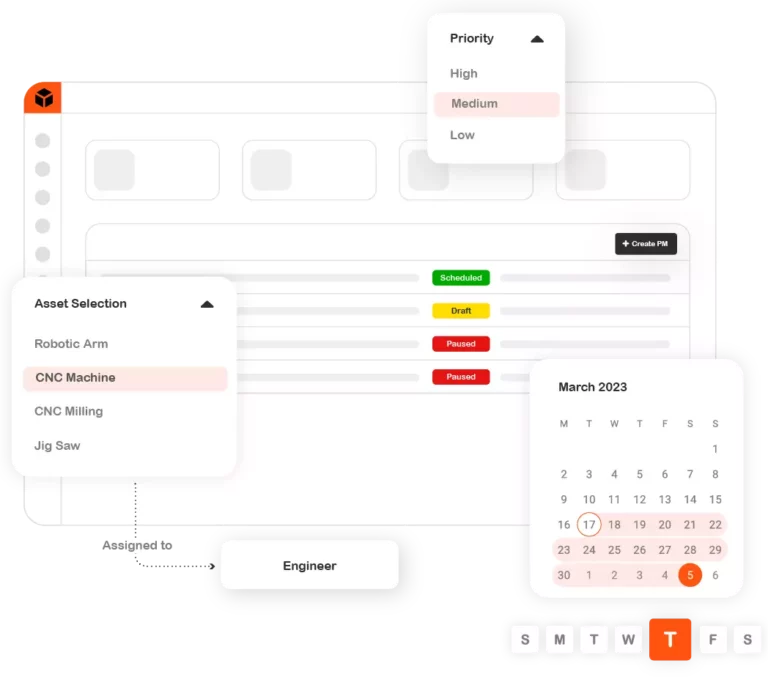

Automate Preventive Maintenance Schedules

Schedule your preventive maintenance orders with just a few clicks. Let Fogwing CMMS Software take the responsibility to automatically create preventive maintenance work orders and assign them to the respective team.

Schedule preventive work orders on daily, weekly, monthly or periodic basis.

You can pause or cancel the preventive work order anytime if it is not required anymore.

Keep track of your preventive work order vs on-demand request to justify the maintenance efficiency.

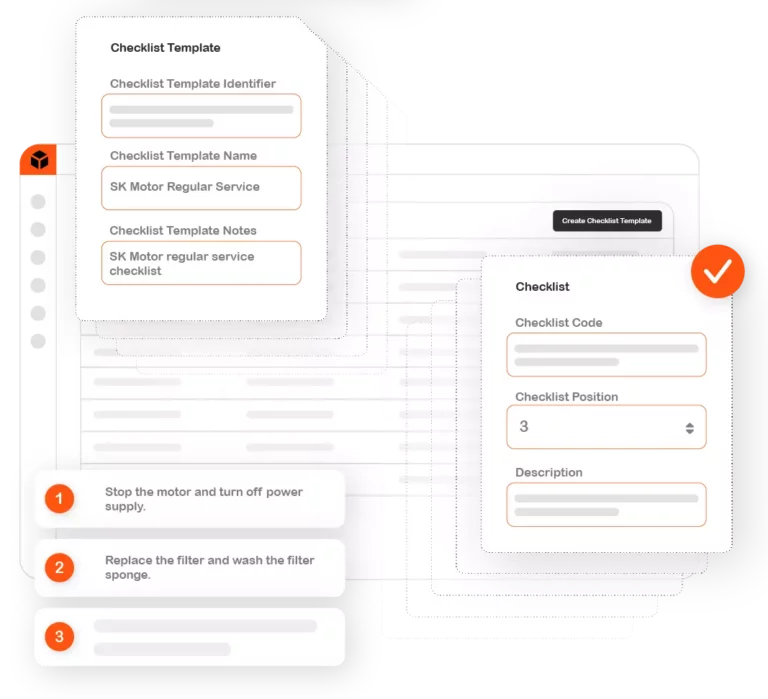

Enforce maintenance precisions with AI-powered procedures.

Create repeatable maintenance checklist and standard operating procedure as template. Enforce the checklist process as part of the work order for uniformity across team.

Easy to create checklist with standard operating steps using Recommendation Engine powered by OpenAI Generative AI. Reduce your paper based instructions or emails.

Assign the checklist to any asset or inspection work orders to enforce the process.

Let the maintenance engineers report the completion of the checklist as part of the work order completion. Instantly get ready for compliance reports.

Ease Parts Allocation and Inventory Management

Materials and parts availability are critical to completing the maintenance request on time and complying with the SLA. Fogwing CMMS Software simplifies this through inbuilt inventory management functions.

Create and Manage list of materials and parts information, variations, quantity, available locations in one place for quick access.

Allow Maintenance Engineers to reserve the parts against work order for on-time completions.

Keep track of parts cost against work order to accurately calculate the overall maintenance cost.

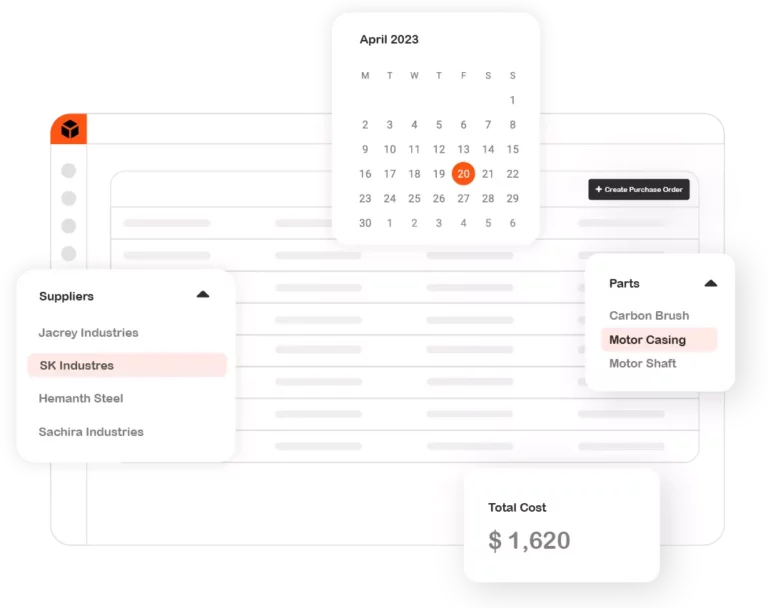

Automate Purchase Order and Stock Updates

Fogwing CMMS Software provides Purchase Order module to prepare PO for a supplier to place the parts orders. As the goods received at the warehouse, update the stock inventory through receivables.

Create Purchase Order with multiple line items, quantity requirements and itemized cost estimation.

Keep track of PO status, batch, lot and timeline of stocks to backtrack any recalls or defective items.

Single source of truth for all parts inventory, stock availability, PO and receivable.

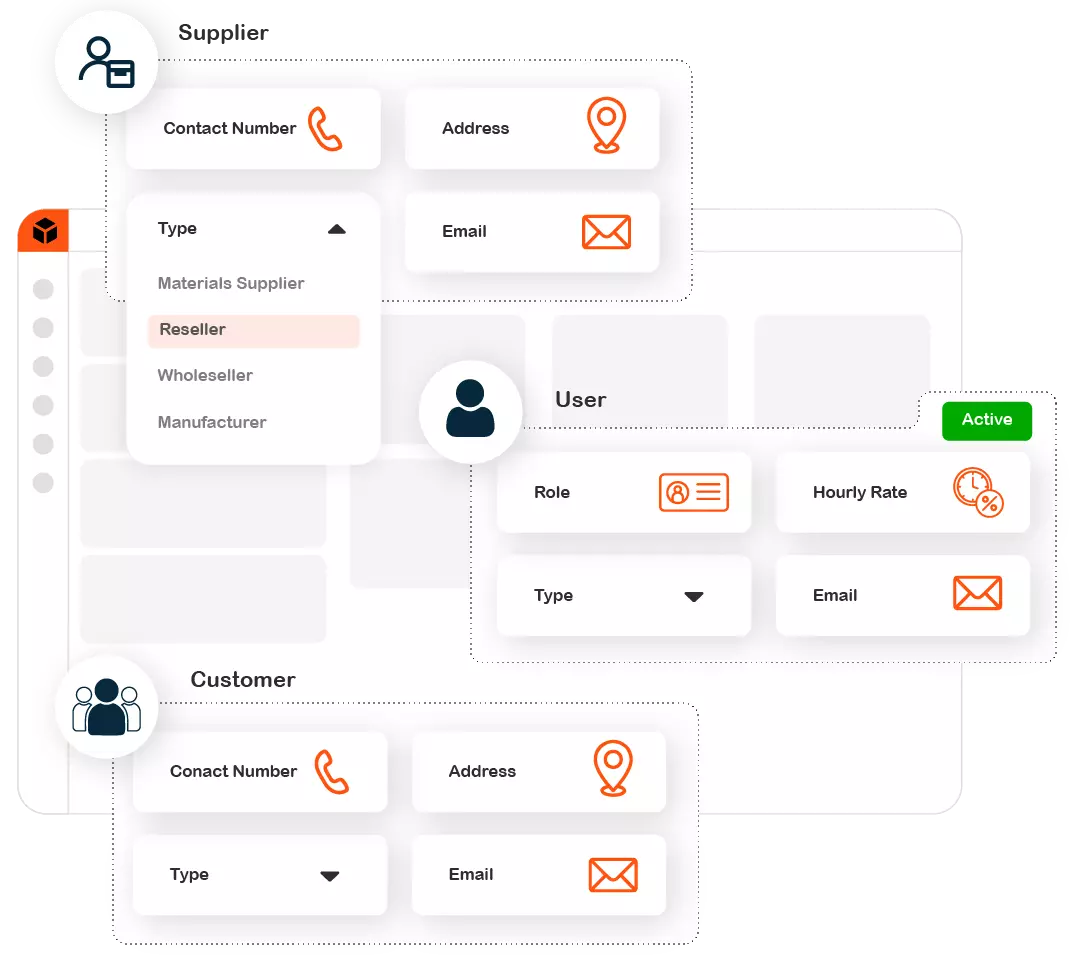

Track Vendors and Supplier Performance

For collaborative maintenance operations, all information should be available in one place for faster and easier access. Fogwing CMMS Software allows you to create and manage suppliers, customers and field engineers in one place.

Add, modify and manager customers, suppliers and user master data for unified maintenance management.

Integrate with existing CRM, SCM and HR Management system through API Integration for seamless data sync.

Create and manage maintenance team members contact, rate card and availability for work order assignments and payroll calculations.

Get the Power of AI Copilot to Assist Maintenance Team

Boost your productivity with AI Copilot Assistance! Integrated into the app, our advanced OpenAI Chatbot offers real-time support, personalized suggestions, and streamlined assistance, empowering you to accomplish tasks more efficiently. Upgrade now to experience the future of collaboration!

Quickly Access Maintenance and Performance KPIs

Fogwing CMMS Software for Manufacturing has an inbuilt analytics engine that performs algorithms to capture various maintenance metrics and key performance indicators for easier presentation.

Provides Work order metrics including WO Trends, WO Completion, Pending, Deployed etc.

Asset metrics provides complete visibility in asset's MTTR, MTBF, preventive maintenance effectiveness through comparisons.

Cost metrics are provides visibility in top expensive assets, top expensive parts and high performing labor cost etc.

Download any metrics and charts as image or data to present to your management team as part of your monthly report.

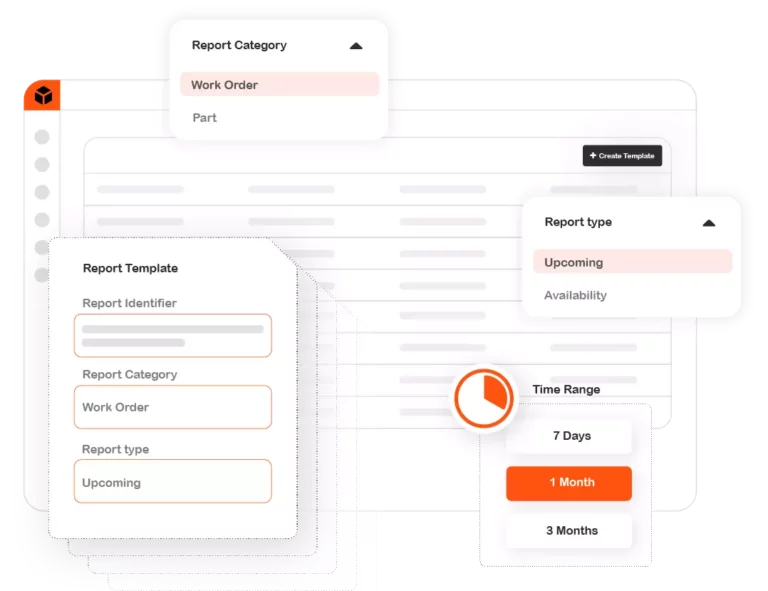

Generate and Download Maintenance Reports

In addition to metrics and charts, Fogwing CMMS Software also provides feature to create custom reports. You may chose the asset, metrics and parameters to generate report template which can be used to create report automatically.

Select the types of report, date range and unique report name to configure the template. Just one-click on Generate-Now to download the reports.

Export the report data as CSV and PDF files. Automate the report delivery through email (coming soon).

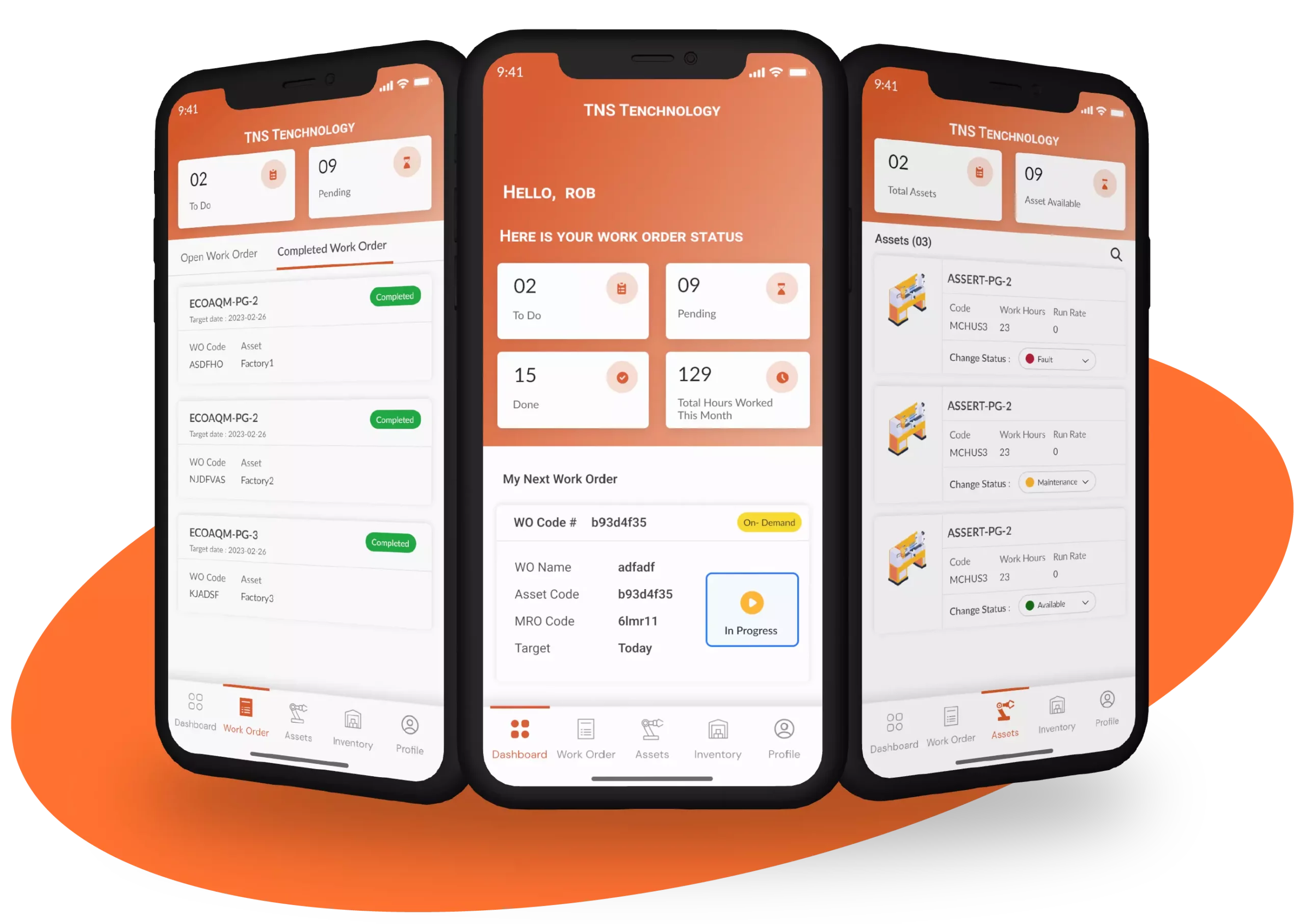

Mobile CMMS for Maintenance Heroes

Mobile App for Mainteance TEam

Access assigned work orders information, compliance checklist and report work hours.

execute work orders

Start, Progress and Complete Work Orders based on the priority and asset conditions using mobile app.

Allocate Parts Required

Allocate parts according to asset condition and complete your work schedule as planned.

Integration

Integrate With Any Business Systems for Seamless Data Sync

Integrate Fogwing CMMS Software with your ERP, CRM, Finance, Payload, or any BI tools to automate data flow between CMMS and other systems. You have complete freedom to build your own integrations that are required for your operations.

Values driven by Fogwing CMMS Software!

01.

Increase Asset Availability

Automated the preventive maintenance and work allocations to manage the asset maintenance operations for preventing unplanned downtime, unpredictable faults and production losses.

02.

No Paper Work, Digitize Maintenance

Stop using excel and notes to manually manage maintenance jobs, work allocation, and tracking. Start using Fogwing CMMS to digitally manage entire maintenance operations from anywhere and anytime.

03.

Reduce Maintenance Operations Cost

Plan and schedule maintenance work orders and priorities based on the metering such as vibration, energy, usage data to accurately plan maintenance schedules. Reduce operational expenses up to 30% through efficiency.

04.

Achieve higher ROI

Well planned maintenance operations helps to extend the life of the machine and lowering the production loss. Achieve higher return of investment from the assets. Increase the productivity to boost the ROI further.

05.

Integrate IoT for Remote Access

Fogwing Edge helps to connect with any assets to read the machine parameters. Automate the metering to gather data, predict problems ahead, automate maintenance and control assets remotely.

FAQs

CMMS Software FAQs

CMMS Software, aka Computerized Maintenance Management System, is a software application that helps the maintenance team to digitalize the day-to-day maintenance operations such as asset information management, maintenance request handling, maintenance work order management, work assignment, parts allocation, preventive maintenance schedule, and work summary, etc. IoT enabled CMMS software automate maintenance work based on the asset condition monitoring and predictive algorithm. AI-power CMMS software helps the maintenance team gain wider knowledge and insights into technical maintenance, checklist enforcement, automate operations.

Generally, CMMS software improves maintenance operations by enforcing a structured and efficient work direction approach to managing assets and maintenance tasks. With data accessibility through mobile devices, the maintenance team will get powerful insights about assets, maintenance history, conditions man, manufacturer datasheets, etc. Automating preventive and predictive maintenance helps ensure high accuracy and leads to lower asset downtime and better production.

Fogwing CMMS Software is available as a cloud subscription with tier-based licensing. Click here for more details about pricing and a feature comparison.

Fogwing CMMS Software is carefully designed to meet practical processes followed by the manufacturing industry. so Fogwing made for Manufacturing Asset Maintenance Management and Operational purposes. Compare with other traditional CMMS Software which made for all different industry, does not cover the deepth of operational uniqueness of manufacturing operations.Fogwing CMMS Software is specifically designed to address the practical processes of the manufacturing industry. It is tailored for manufacturing asset maintenance management and operational purposes.

Unlike traditional CMMS software, which is designed for various industries, Fogwing focuses on the unique operational requirements of manufacturing operations.

Fogwing CMMS Software includes a mobile app for maintenance engineers to access maintenance work orders, follow instructions, get parts inventory, allocate work assignments, and complete them from the field. Explore more about our mobile CMMS.

Fogwing Platform supports Open APIs for third-party integration. Through API interfaces, your existing ERP applications, such as SAP, Oracle, Infor, and Salesforce, can be integrated with Fogwing. In addition, Fogwing Team also provides custom integration between Fogwing and third-party applications through data pipelines.

Fogwing Platform is compliant with security standards, including SOC 2, ISO 27001 & ISO 27701. It also supports role based access control (RBAC), multi-factor authentication (MFA) and data encryption.