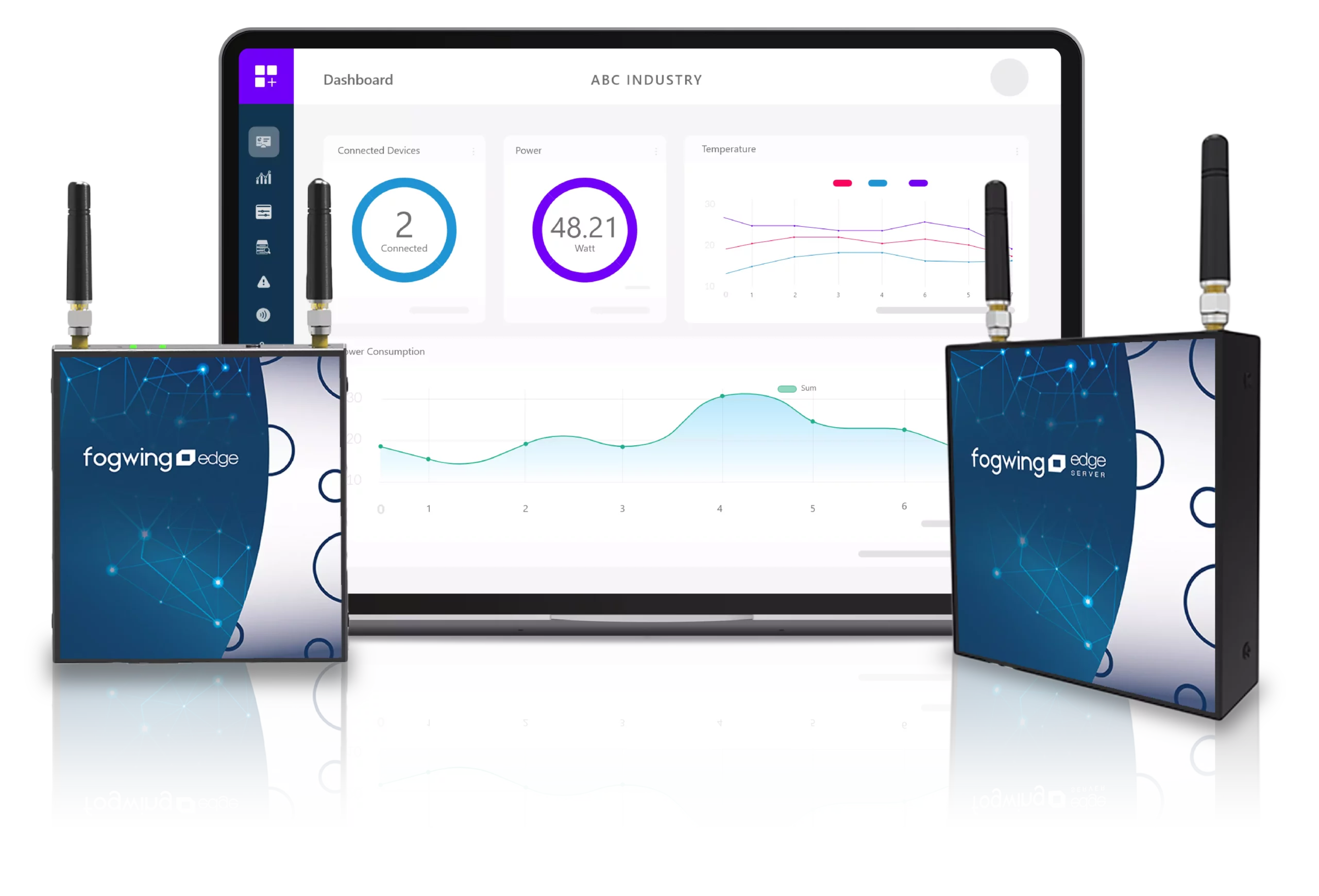

Industrial Edge Devices for Machine Monitoring

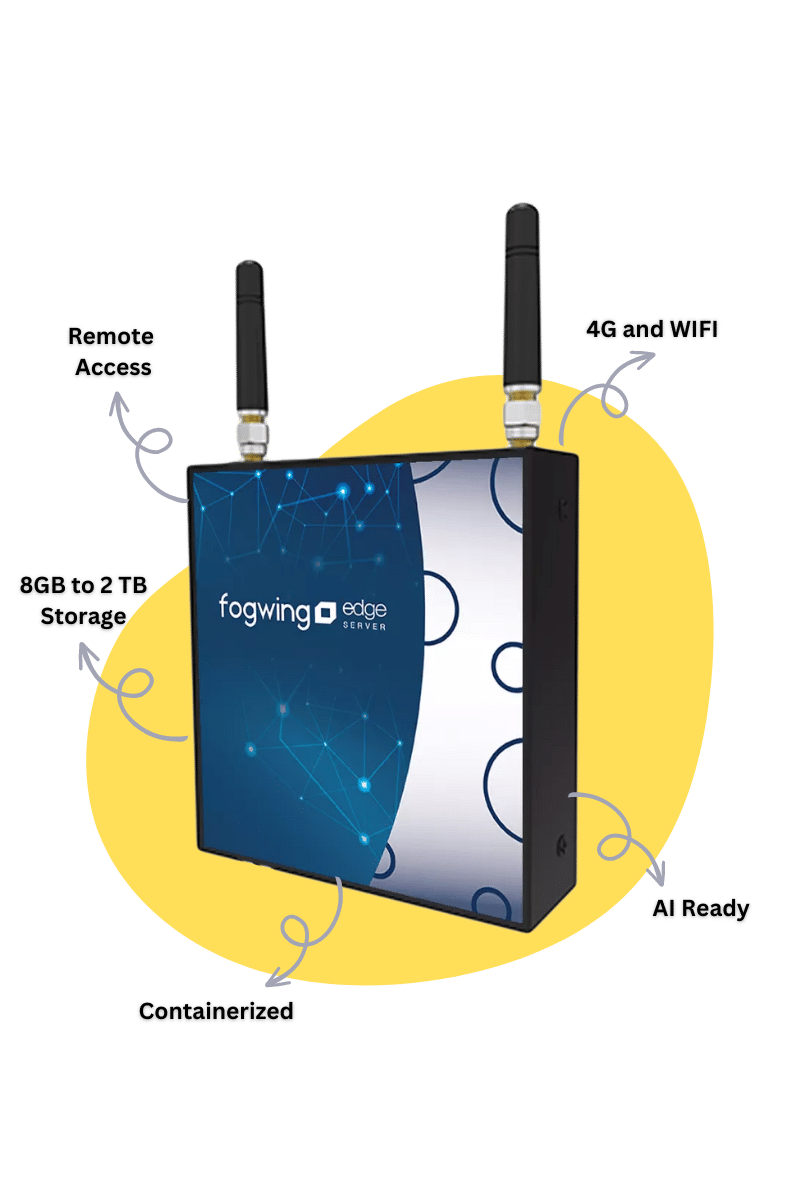

The most affordable Industry grade edge devices for connecting with your factory machines, PLC and Sensors to collect operational data for data aggregation and processing directly with Fogwing Industrial Cloud.