Automotive Manufacturing

Digitalize Parts Manufacturing

Connect with your machines using IoT technologies for higher visibility in production operations, compound preparations, effective machine operations, faster delivery with profitability

Connect with your machines using IoT technologies for higher visibility in production operations, compound preparations, effective machine operations, faster delivery with profitability

Traditional production planning and execution approach is of low competitive advantage. It’s best to digitalize the production planning and execution as a software driven practice.

Real-time visibility of production efficiency from anywhere in the world.

Get quick access to allocate / route the work orders depending on the slow cycle and machine efficiency.

Prepare production schedule and job allocations based on demands and track good quantity, rejection and cost of completion.

Capture and monitor the production process data using Industrial IoT connectivity and cloud storage solution.

Measure the materials usage, composition data, processing parameters for quality controls.

Track the machine runtime, downtime, cool down time and material distributions for performance metrics.

Protect the environment from spillover and leakages by monitoring the flow of materials through pipelines.

Every machines availability and performance is critical for efficient manufacturing operations. Maintenance is the key.

Start reading machine runtime, vibration, temp and energy consumptions using IoT technologies.

Measure, Compare and Analyze the machine health trends and fault frequency to predict maintenance requirements.

Plan and execute preventive maintenance of machine based on the prediction of machine health conditions for lower downtime.

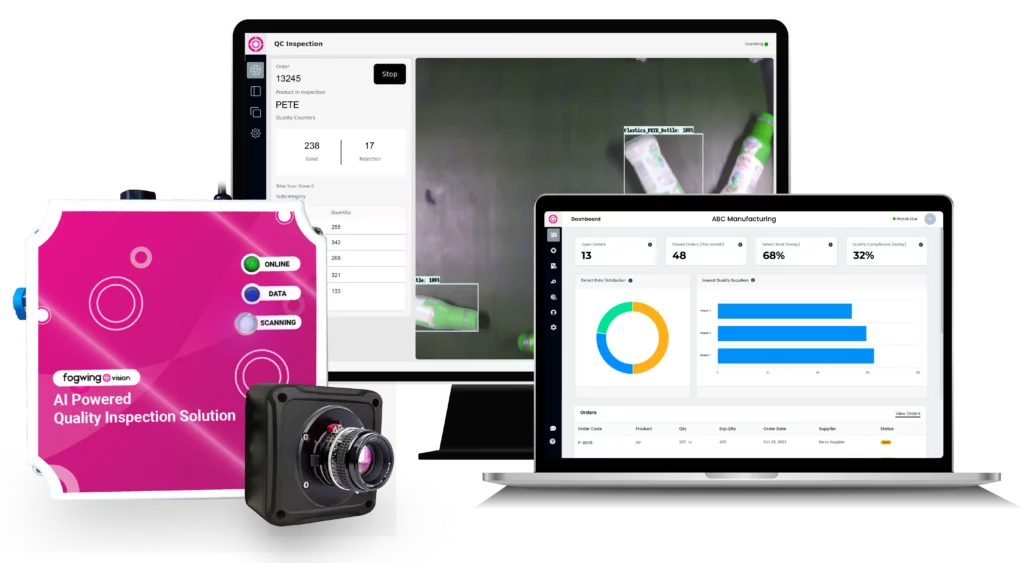

Automated vision system for quality inspection to detect fault, damage and rejections of parts from production floor.

Real-time visibility of defective parts through AI driven vision sensing solution.

Faster and accurate way to inspect all parts from production machines rather than sampling.

Accurately capture the good quality vs rejection counts against production orders for real-time operational visibility.

No more paper ledgers to track the tools and allocations. Start using software based tool management solution for tool usage tracking.

Complete inventory of tools, usage level, allocations and readiness.

Digitized tool allocations, approval and rental processes at real-time.

Track the tool locations, lifetime, usage and cost of depreciation.

Plan and execute tool repairs, refurbishment, times of usage for high availability.

Reduce Inventory Cost of Goods

Increase Productivity Rapidly

Quickly Reduce Machine Downtime

Increase Production Throughput

Improve Accuracy in Forecasting

Increase Total Cost of Quality