Cloud MES Software for Digital Operations.

Transform your shop floor operations with MES software to achieve agility, operational excellence, enhanced quality compliance, and maximize your return on investment (ROI).

Transform your shop floor operations with MES software to achieve agility, operational excellence, enhanced quality compliance, and maximize your return on investment (ROI).

MES Software provides functions and processes to prepare, plan and execute factory floor operations uniformly, track progress at real-time and increase agility to align as the day demands.

Fogwing MES / MOM Software provides all features required to run lean manufacturing operations. The inbuilt AI-based Manufacturing Intelligence module provides Performance KPIs, Downtime Alerts, Loss based Metrics, Scrap Trends, MTTR and MTBF etc.

Simply create manufacturing work orders for each sales orders to kickoff the production across work center and plant.

Create work orders against customer sales order

Automatically keep track of work order status and percentage of completion according to floor level job completion

Clone any work order to create recurring orders.

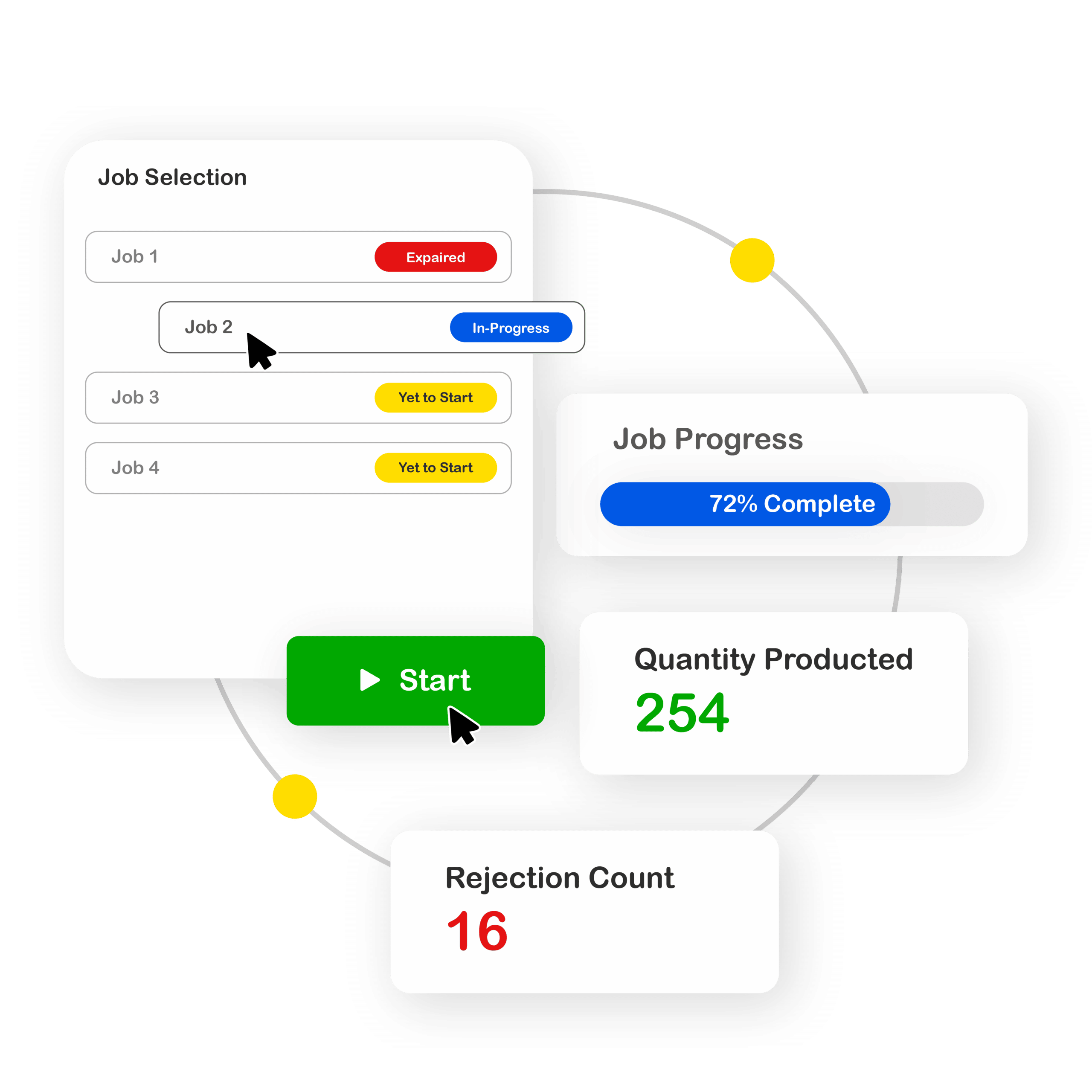

Create jobs against work orders and assign to machine operators to execute according to the production plan.

Breakdown work orders into multiple jobs for operators

Allocate machine and operators for the job execution based on availability.

Clone, allocate and track the job progress across work center and plant.

Configure manufacturing parts, materials and BOM structure, stock availability and product cycle time for accurate planning and execution.

Create and manage parts availability, stock and production planning

Define raw materials, availability and stock updates in just a few clicks

Define simple and complex Bill of Materials (BOM) and processes as template for rapid job allocations.

Execute production jobs, track machine status and capture the quantity and rejection counts for real-time tracking. Automate it through IoT connectivity.

Operator may pick the job according to priority and start the production on-time

Capture the maintenance history for asset and performance prediction

Plant, Work Center, Assets, Customers, Work Order, Jobs and Rules.

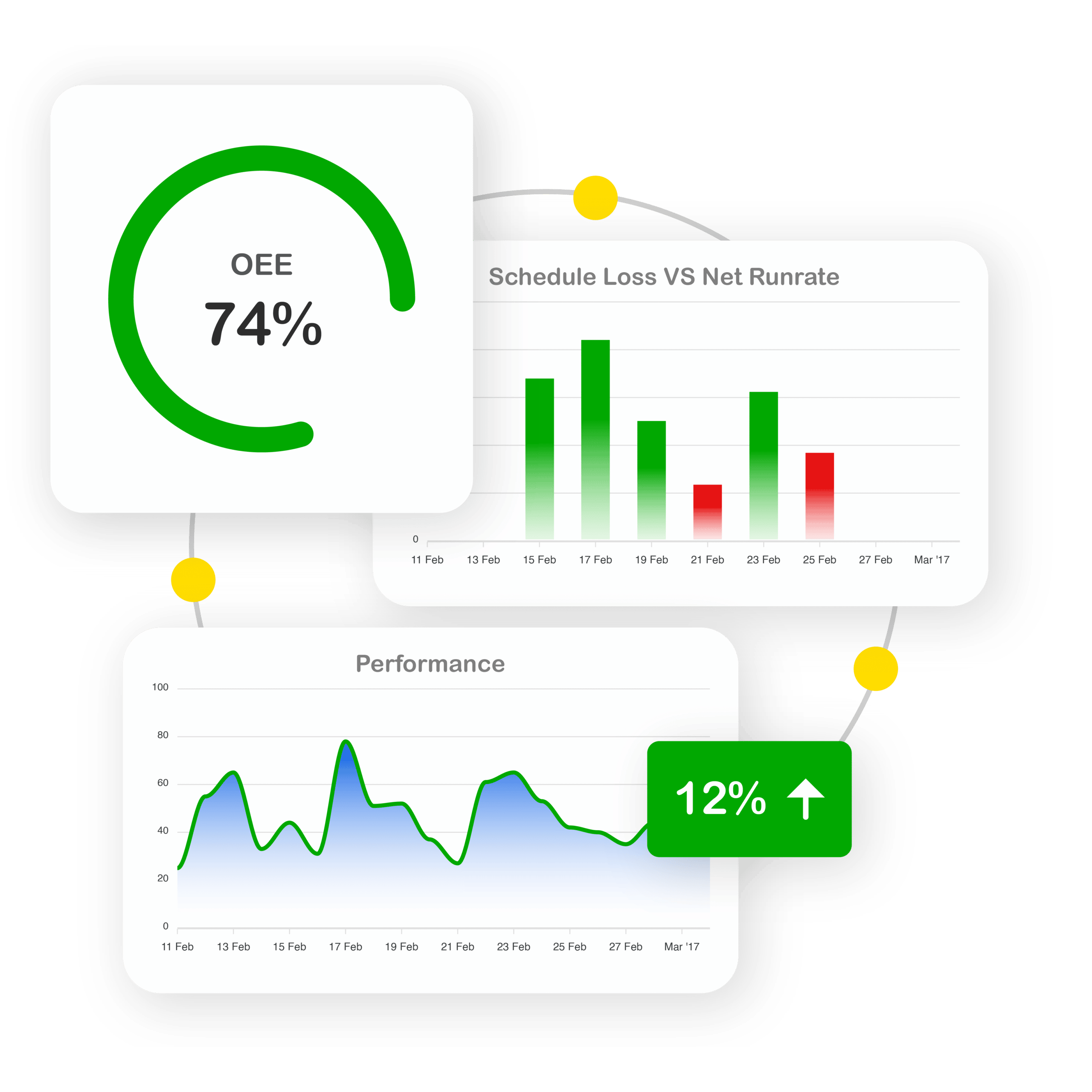

Monitor and Track the performance of assets and production processes in a single window of application. Simply configure according to your priorities and get alerts relating to production issues.

Set your own dashboard by picking plant, work center or assets

Track the Downtime and Net Runtime at the plant level

Monitor the progress of the work orders and assets status from dashboard

Prepare and send maintenance request as Fault, Preventive or machine condition based. Let’s capture the maintenance history to prediction.

Operator and Manager can create MRO request as need basis.

Schedule, track and prevent the machines failure at peak hours

Keep track of open tickets and closure with high visibility

Time is cost in the manufacturing business. Factory’s operational efficiency is influenced by the execution time of work deliverables. Monitoring and Tracking runtime and downtime of each asset is practically not possible in traditional reading techniques. With just one click, Plant Manager can view the performance metrics of each asset as time-based metrics.

Metrics Includes: Runtime Vs Downtime, Planned Production Vs Schedule Loss, Net Runrate, Production Vs Quality Loss.

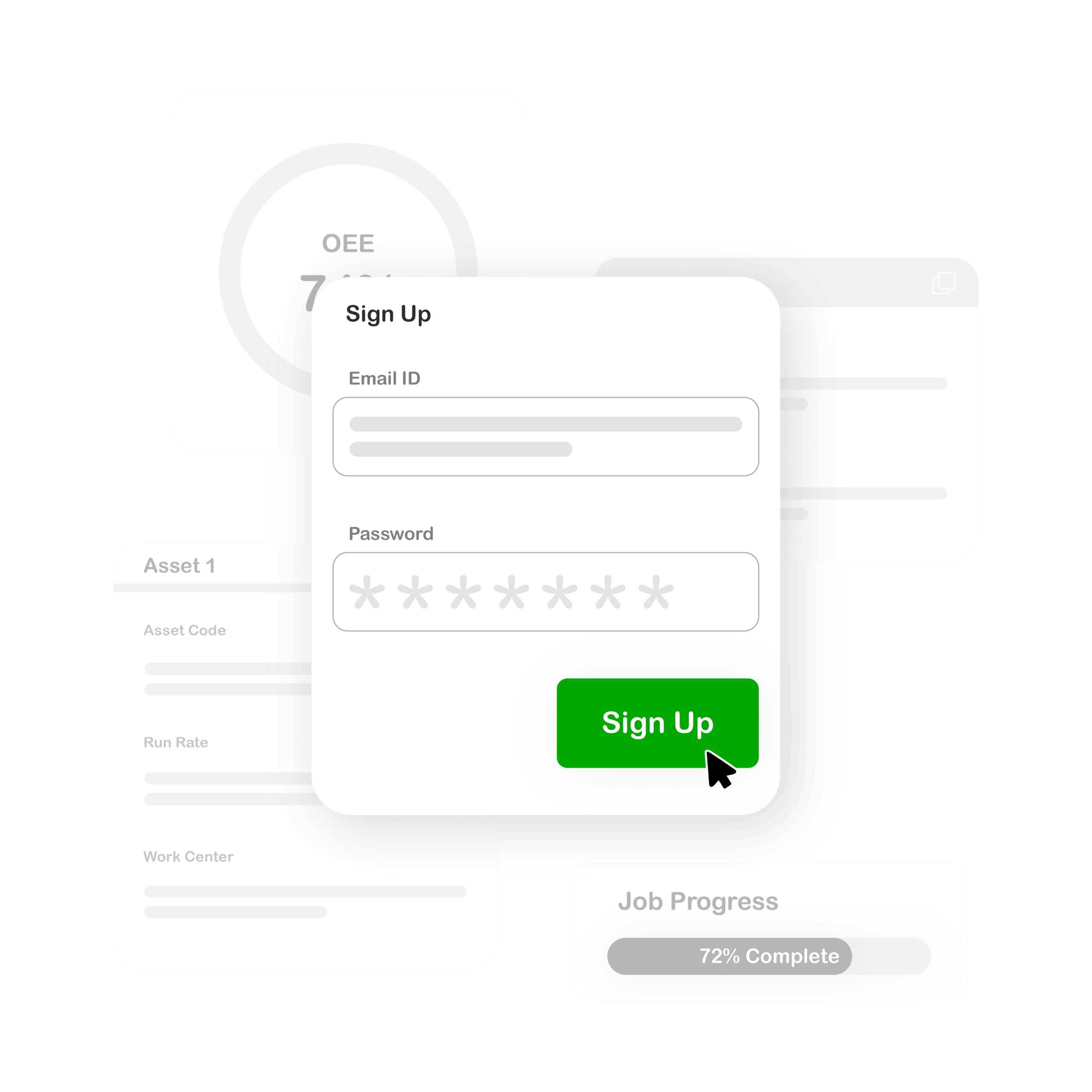

Fogwing MES is designed as business user friendly to enable quick configuration of the plant organization setup. Simply create an account and set your plant structure by yourself. Fogwing MES is a Cloud Software, No Download, No Installation, No technical skill required.

Setup includes: Plan, Work Center, Assets, Customers, Work Order, Jobs and Rules. Step by step guided tour feature will help you to set your organization structure properly. Still need support, write to us.

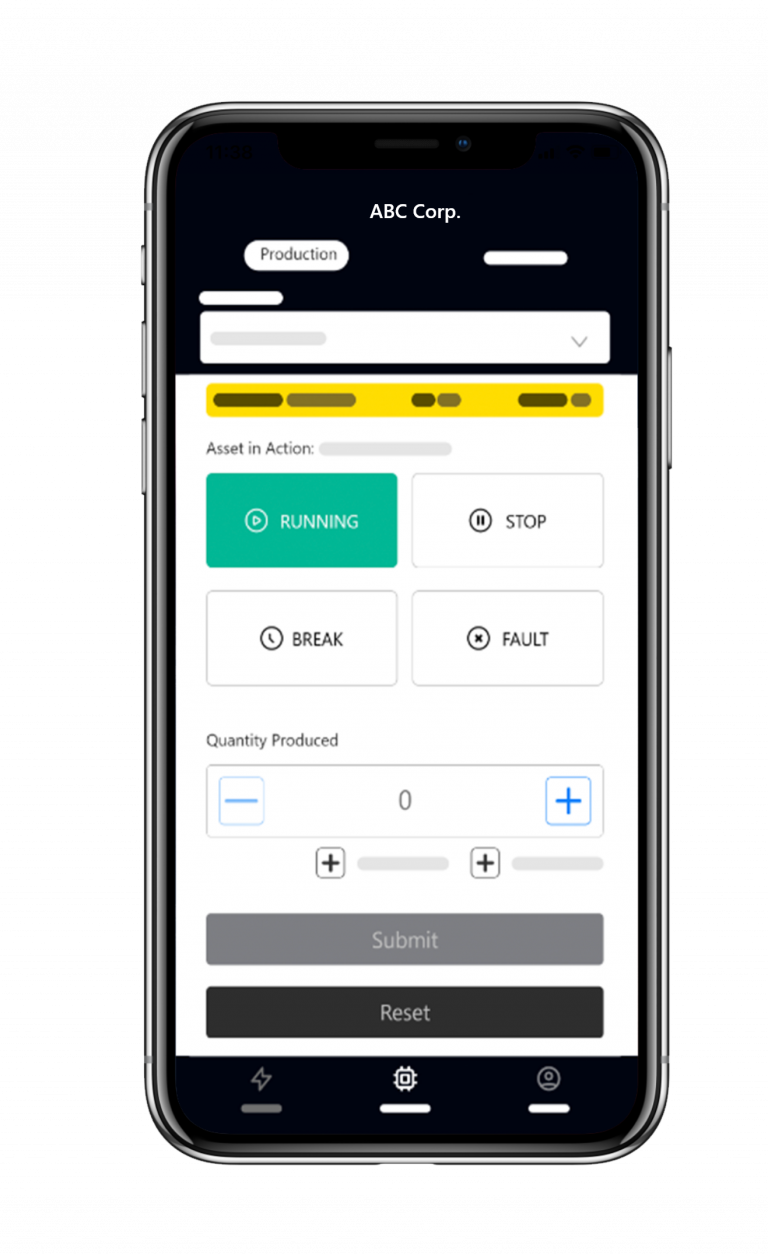

Operator may self check the Job accomplishment and improve effciency.

Machine Operator records machine status manually or through IoT connectors.

Quality Controller updates the good and scrap counts instantly in the app

Machine Operator instantly reports machine faults with a single click to alert maintenance.

Cloud hosted Manufacturing Intelligence Software as a Service. No upfront investment . Low operational expenses.

Accessible in Desktop and Mobile from anywhere. No installation or configuration required. No HMI required.

Prebuilt integration with Fogwing IIoT Platform. Just connect any equipment and start tracking the performance.

Personalized Demo, Documentation and Training programs to support. 12x5 operational support services.

In the Era of industry 4.0, live monitoring of OEE is essential. It saves non valuable time of data collection, OEE calculation in spread sheet & analysis of trend basis on the past data. This Fogwing MES platform is helping us for line efficiency improvement thru proactive action on the factors affecting the OEE. All the machine faults or breakdown can also be captured real time with cause & total down time.

Praveen Thomar

- Plant Manager