Manufacturing Process Monitoring Software

Capture production process data from your machines and operators at realtime to monitor operational process performance. Get visibility and act faster to meet the demands.

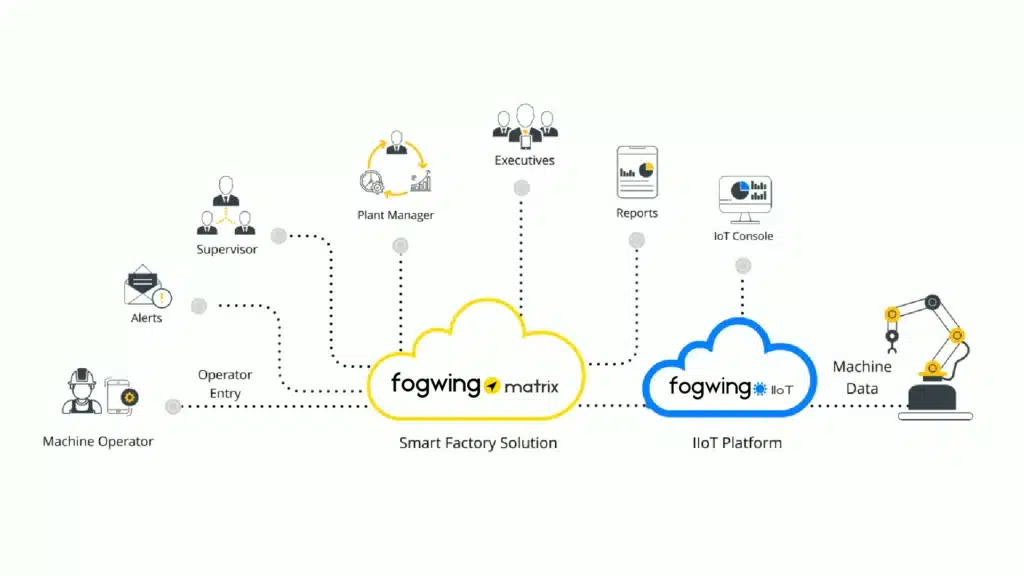

IoT for Real-time Production Process Monitoring

IoT integration helps to capture the machines availability, performance and productivity data. Operators inputs captured from HMI added to the centralized data processing engine to prepare the process metrics. All manufacturing stakeholders get access to the process data for realtime manufacturing process visibility.

From Shop Floor to Top Floor. One Solution.

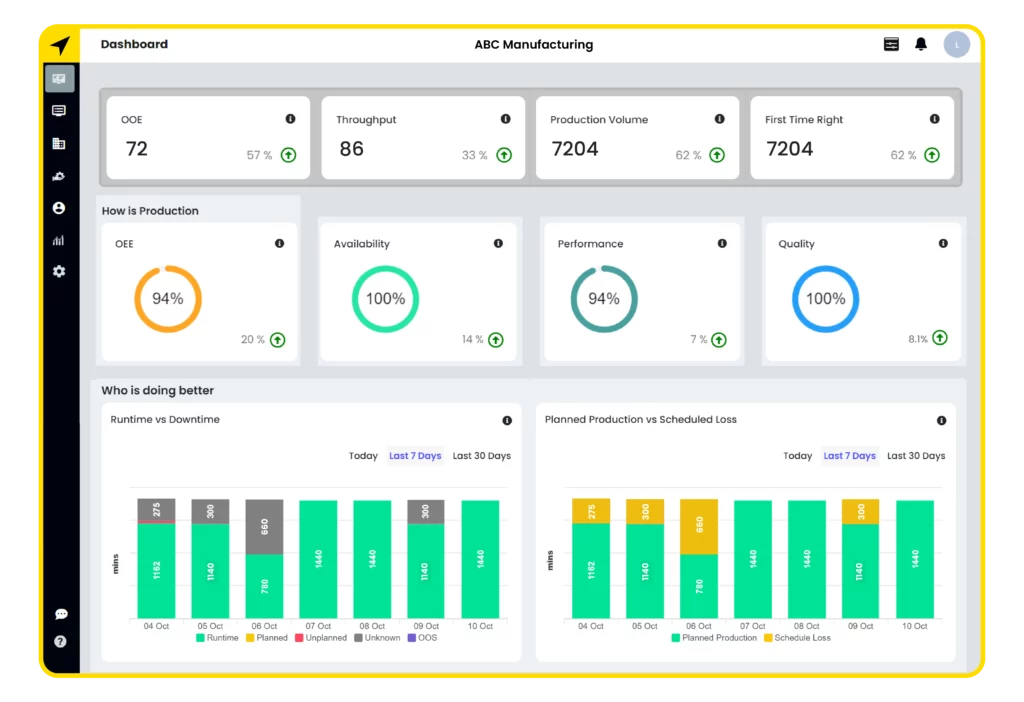

Dashboard with KPI Metrics

Monitor and Track the performance of assets and production processes metrics in a single window of application. Simply configure according to your priorities and get alerts relating to production issues. While measuring the performance metrics, compare the productivity against the work order to measure the completion ratio.

Metrics Includes: OEE, Operation Timing, Quantity vs Scrap, Work Order Progress etc.

Time based Metrics

Time is cost in the manufacturing business. Factory’s operational efficiency is influenced by the execution time of work deliverables. Monitoring and Tracking runtime and downtime of each asset is practically not possible in traditional reading techniques. With just one click, Plant Manager can view the performance metrics of each asset as time-based metrics.

Metrics Includes: Runtime Vs Downtime, Planned Production Vs Schedule Loss, Net Runrate, Production Vs Quality Loss.

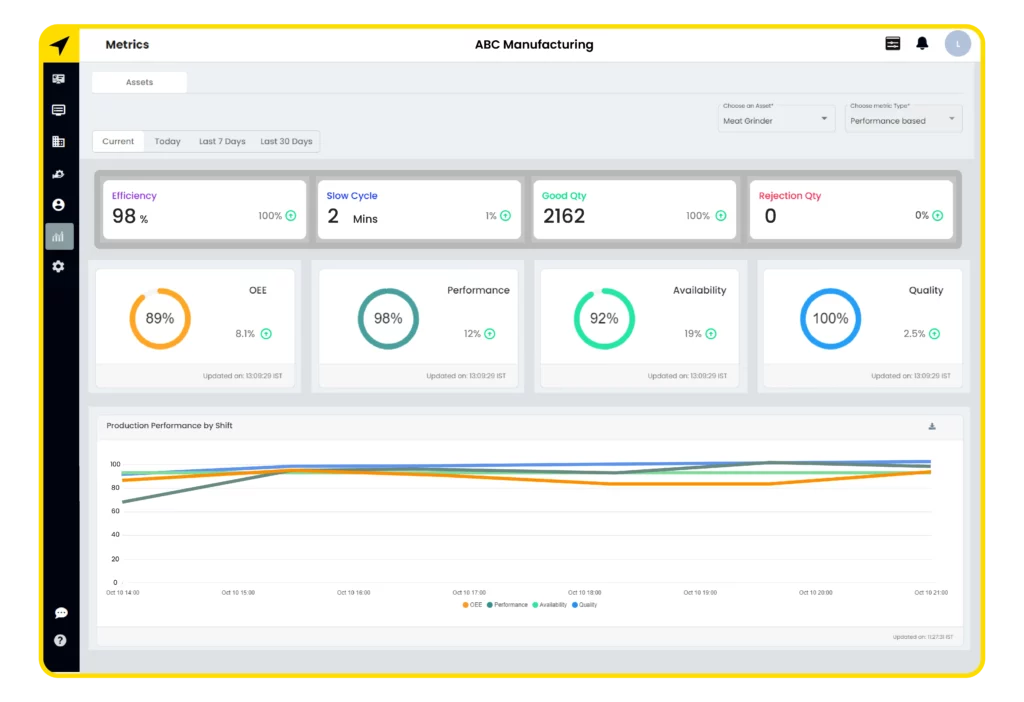

Production Loss Analytics

Monitoring OEE is one of the many ways to measure actual production efficiency. But OEE does not provide the efficiency loss against total potential of the equipment or TEEP (Total Effective Equipment Performance). SFactrix Software facilitates to measure the Production Loss based Metrics by drawing comparisons with OEE. Just a click away. No addition efforts required.

Metrics Includes: Availability Loss, Performance Loss, Quality Loss and TEEP.

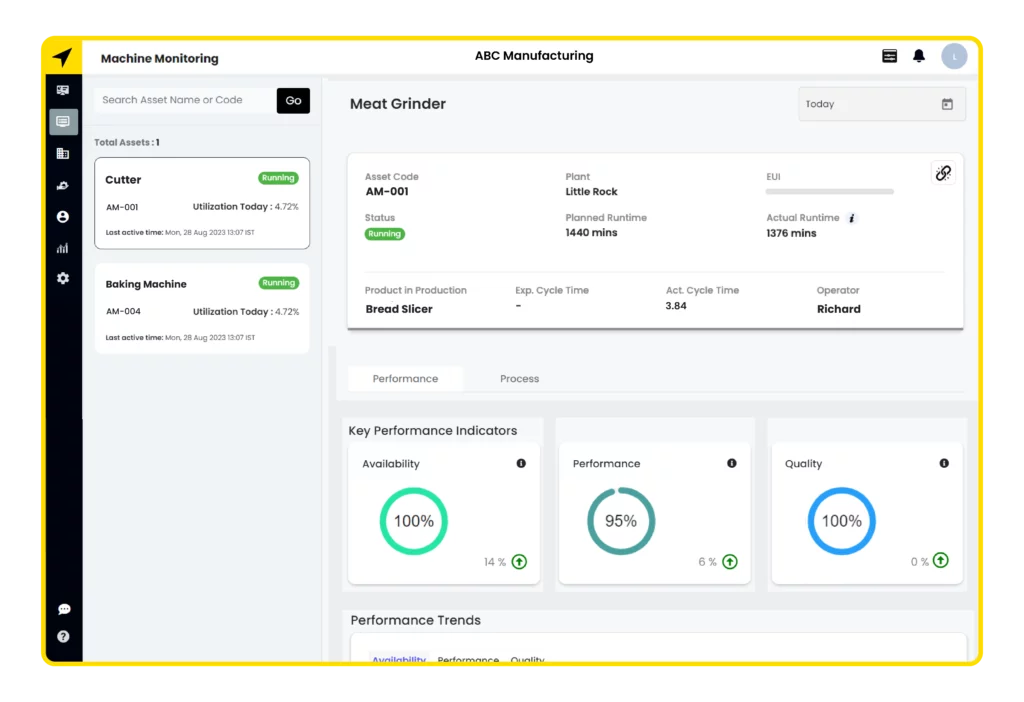

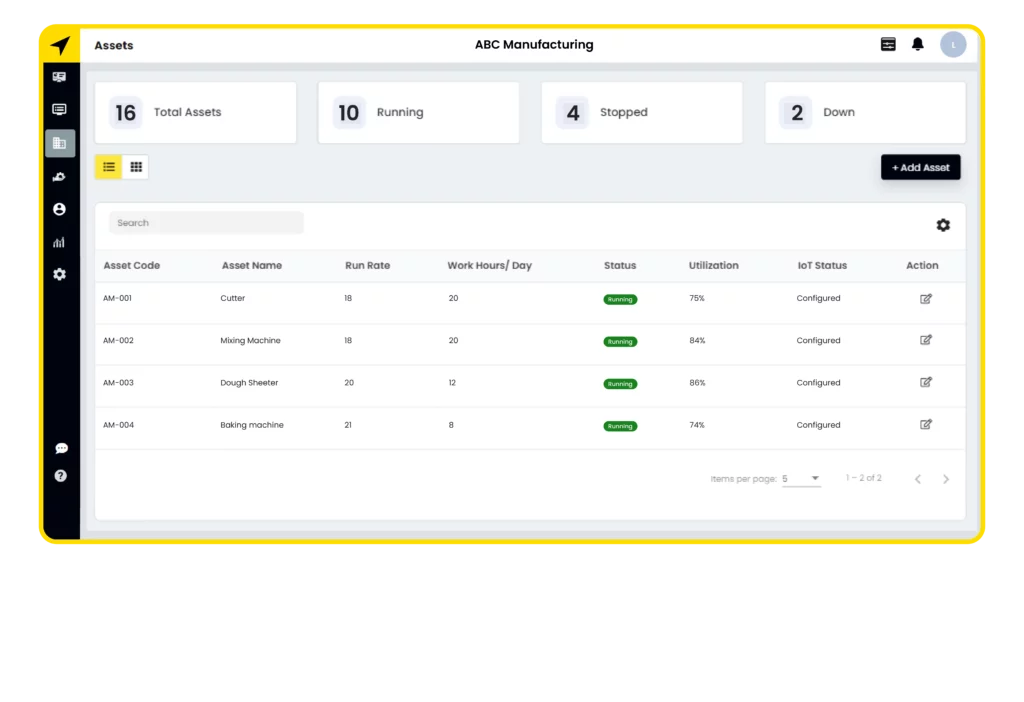

Machine Downtime Tracking

Understanding asset’s capacity, run rate, lead time and current status are critical in the creation of manufacturing plans and schedules accurately. Plant Managers can see the asset’s current status and other metadata easily as part of asset management feature.

Quick and hassle-free way to get access to better control manufacturing machines.

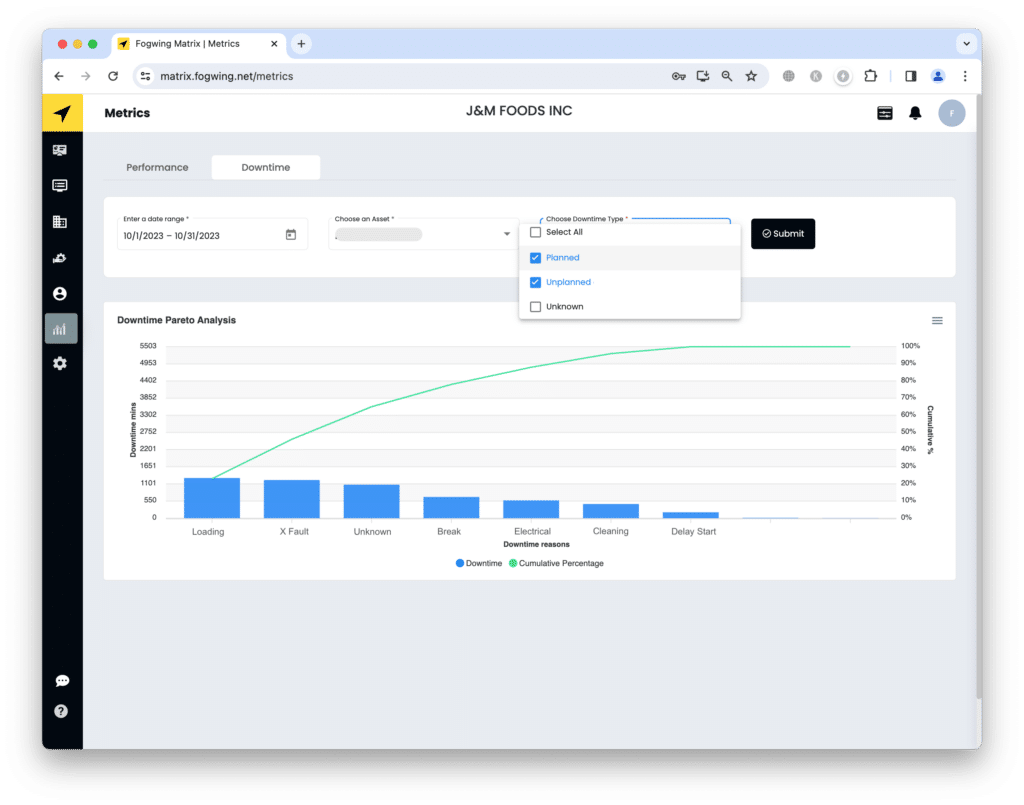

Downtime Trends and Pareto Analysis

The value of Fogwing Matrix downtime Pareto analysis lies in its ability to guide strategic decision-making, optimize resource allocation, and ultimately minimize downtime, contributing to a more resilient and high-performing production operation.

Metrics Includes: Pareto analytics of machine downtime for planned and unplanned.

Manufacturing Process Monitoring Software as a Service.

subscription software

Cloud hosted Manufacturing Intelligence Software as a Service. No upfront investment . Low operational expenses.

HMI Interface

Accessible in Desktop and Mobile from anywhere. No installation or configuration required. No HMI required.

Industrial IoT Integration

Prebuilt integration with Fogwing IIoT Platform. Just connect any equipment and start tracking the performance.

customer Support

Personalized Demo, Documentation and Training programs to support. 12x5 operational support services.

Trusted by Leading Manufacturers

In the Era of industry 4.0, live monitoring of OEE is essential. It saves non valuable time of data collection, OEE calculation in spread sheet & analysis of trend basis on the past data. This SFactrix platform is helping us for line efficiency improvement thru proactive action on the factors affecting the OEE. All the machine faults or breakdown can also be captured real time with cause & total down time.

Praveen Thomar

- Plant Manager