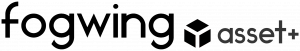

IoT Device and Sensors

High performance industry grade device with current, vibration, noise and temperature sensors. Just Plug-and-Plug installation.

Industrial IoT Integration

Prebuilt integration with Fogwing IIoT Platform. Just connect any equipment and start tracking the performance.

WIRELESS COMMUNICATION

Fogwing Asset+ devices are available with WIFI, 4G network connectivity. Inbuilt SIM module helps to deploy at global scale.