This article provides information about SFactrix MES Release Note September 2022.

SFactrix Smart MES manufacturing metrics and KPIs are real-time statistical representation of the production performance analysis that drives efficiency. SFactrix metrics predominantly help the shop-floor users to access, compare and track the efficiency and performance of the assets, or the overall production unit. The metrics data enable plant manager to take quicker decisions and necessary steps to improve production performance, efficiency, and quality.

SFactrix is also an IoT integrated Smart Manufacturing Execution System that helps SME manufacturers to digitalize production execution and automate factory floor operations. SFactrix is truly a one-stop MES solution for complete factory digitalization. Our Engineering Team is constantly working on adding and upgrading features and functionalities to enable users to run the factory floor operation in real-time.

SFactrix MES Release Note September 2022

In this SFactrix MES Release Note September 2022 (V2.0), the major up-gradation is done on metrics and KPIs engine to provides better accuracy in terms of analyzing Assets performance trends, Fault trends, and Quality production trends.

The following are some of the high level improvement made in this release.

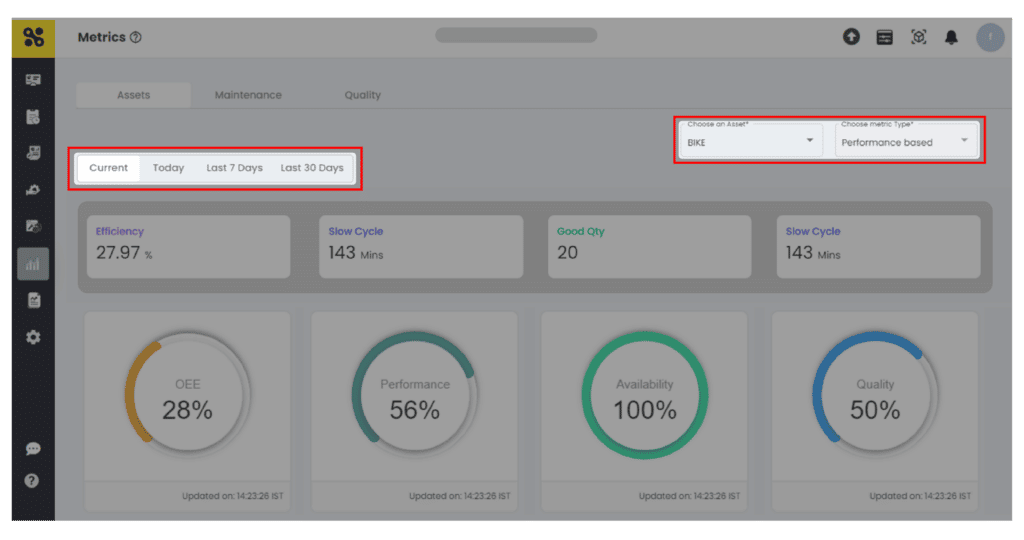

Asset Performance KPIs

Asset performance metrics and KPIs are re-designed and calculated based on the work-center shift hours to keep a track of Asset’s performance concerning Time-based Metric is available in 3 pages, (1 day, last 7 days, last 30 days) which graphically shows the assets’ data referring Runtime v/s planned/unplanned Downtime, and total planned production v/s schedule loss in every work-center shift. The Time-based Metric also shows OOS (Out of shift) production and productivity.

There are two types of Assets data metrics available in SFactrix.

- Performance-based metrics

- Time-based Metrics

The performance-based metrics are calculated based on the work-center shift hours that provide better accuracy in terms of asset efficiency, performance, availability, quality etc. The performance-based metric data is available in Current shift, Today, Last 7 Days, and Last 30 Days. This advanced metrics provide better accuracy and higher visibility into the assets’ performance.

Time-based Metric is available in 3 pages, (1 day, last 7 days, last 30 days) which graphically shows the assets’ data referring Runtime v/s planned/unplanned Downtime, and total planned production v/s schedule loss in every work-center shift. The Time-based Metric also shows OOS (Out of shift) production.

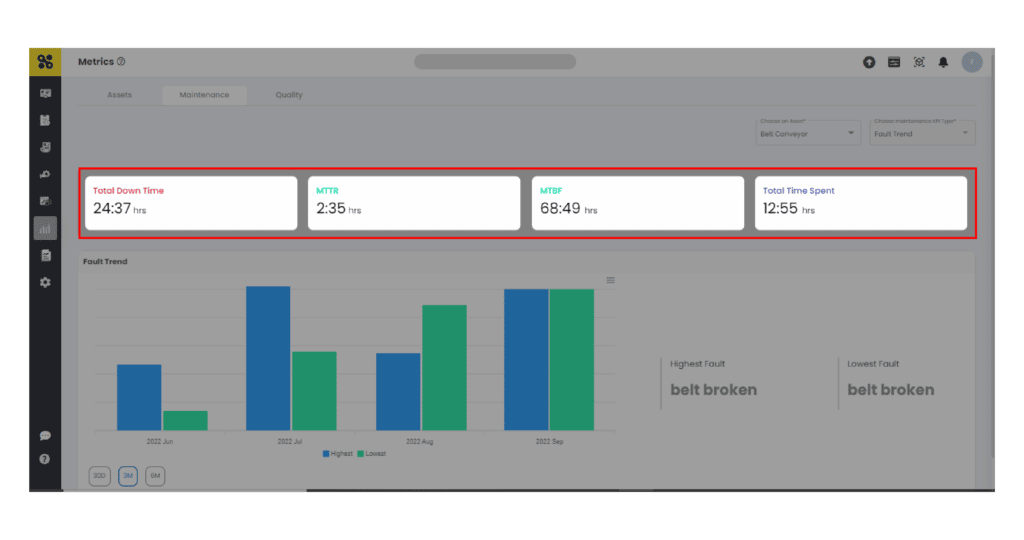

Fault Trend Analysis

Maintenance or Fault trend metrics are generated in the SFactrix using AI powered engine based on the fault reported during production. The fault trend analysis data are available for the last 30 days, 3 months, and 6 months. The metric visualization also includes Total Downtime, MTTR (Mean Time To Repair), MTBF (Mean Time Between Failure), and Total maintenance time. These metric helps the user to avoid such occurrences in the future and obtain peak utilization of the assets to achieve an efficient production rate.

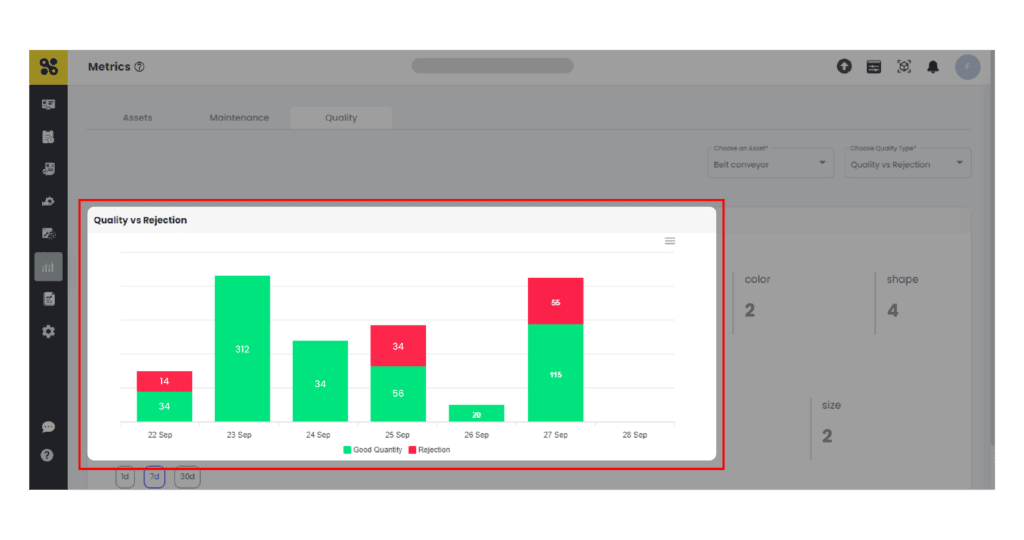

Quality Trend Analysis

Quality Trend analysis metrics are generated on the SFactrix based on the rejections reported production operators. The Quality trend shows two types of metrics such as Quality vs Rejection and Rejection trends. Quality trend metrics allow the factory user to compare between quality production data and scraps or rejection data. The quality trend metrics reports are available for 1 day, 7 days, and 30 days. Capturing production data and quality data helps in calculating the performance and efficiency of the operations.

Conclusion:

The advanced SFactrix metrics and KPI feature by shift is now available for better accuracy. These metrics help the factory users get insight into the manufacturing operations and allow them to improve the assets’ performance, maintenance, availability, productivity, and efficiency.