Smart manufacturing has ushered in a new era of connected systems. It transforms how companies manage their production processes by integrating advanced technologies like AI, IoT, and data analytics. Organizations need a comprehensive asset management policy to maintain efficiency, reduce risks, and manage resources effectively. Such a policy helps streamline the management of physical assets while ensuring they align with long-term business goals. However, businesses need a well-defined management policy for assets to ensure these high-value systems function seamlessly and provide the expected ROI (Return on Investment). In this blog, we’ll explore critical aspects of management policies for smart manufacturing, including the principles and objectives that drive them.

What is an Asset Management Policy?

An asset management policy is a high-level framework that defines how a smart factory or business will manage its physical, financial, and digital assets throughout its lifecycle. It outlines the principles, responsibilities, and strategies to ensure that assets are used efficiently, appropriately maintained, and aligned with the organization’s operational and strategic goals.

The policy typically serves as a guiding document for employees, managers, and stakeholders, ensuring all parties understand their roles and the importance of asset management in driving performance, risk mitigation, and cost efficiency.

What are the Objectives of an Asset Management Policy?

The primary objective of an asset management policy is to align the use, maintenance, and management of assets with the organization’s strategic goals. Specifically, it aims to:

Maximize Asset Value and Lifecycle Efficiency: Ensure that all assets perform optimally throughout their lifecycle, from acquisition to disposal.

Minimize Downtime and Maintenance Costs: Adopt predictive and preventive maintenance strategies to reduce unexpected failures and improve productivity.

Enable Sustainability and Compliance: Promote energy efficiency and align with regulatory standards, contributing to sustainable manufacturing practices.

Facilitate Risk Management: Identify and mitigate risks associated with asset failure, asset data management, cybersecurity vulnerabilities, and obsolescence.

Support Continuous Improvement: Establish performance metrics for ongoing monitoring and optimization of assets through intelligent technologies like IoT.

Critical Considerations for an Asset Management Policy in Smart Manufacturing

Critical considerations for an asset management policy in smart manufacturing include integrating advanced technologies such as IoT, artificial intelligence, robotics, and cloud computing to create highly efficient, connected production environments. However, managing these assets requires a comprehensive and future-ready management policy for assets. Below are the key considerations organizations must address when crafting such a policy to ensure smooth operations, high performance, and long-term sustainability.

1. Integration of IT and OT Systems

The intersection of Operational Technology with Information Technology is at the heart of smart manufacturing, and your policy should outline this.

- Communication protocols between IT systems (ERP, CMMS) and OT equipment (robots, sensors, machines).

- Data-sharing frameworks to enable seamless real-time monitoring throughout the asset lifecycle.

- Governance over how data flows between shop floors and business systems to avoid silos and maintain operational transparency.

Why it Matters: A well-integrated IT/OT environment ensures all stakeholders—operators and executives—can access accurate, real-time insights.

2. Data-Driven Asset Lifecycle Management

In smart manufacturing, assets generate vast amounts of data throughout the asset lifecycle. The asset management policy includes the following:

- Procedures for capturing, storing, and analyzing IoT data from connected assets.

- Guidelines on using predictive analytics to extend the lifespan of equipment through proactive maintenance.

- Policies on when and how to retire or replace assets based on performance metrics.

Example: A connected pump with sensors can alert technicians about performance degradation, triggering predictive maintenance before failure occurs.

3. Cybersecurity Frameworks for Connected Assets

Smart factories are exposed to cyber risks due to the massive usage of connected devices and cloud platforms throughout the asset lifecycle. The asset management policy must address the following:

- Implementation of security protocols and firewalls for IoT devices and networked equipment.

- Policies for regular vulnerability assessments and software updates.

- Access control policies define who can monitor, control, or modify critical systems.

Why it Matters: Protecting connected assets is essential to avoid production disruptions or data breaches.

4. Predictive and Condition-Based Maintenance

An intelligent manufacturing environment demands advanced maintenance strategies to ensure asset availability throughout the asset lifecycle. The policy should specify:

- How will predictive maintenance (PDM) and condition-based monitoring be implemented?

- Integration with a CMMS platform (e.g., Fogwing CMMS) to automate maintenance scheduling and remote asset management.

- Guidelines for tracking Mean Time Between Failures (MTBF) and other performance metrics.

Example: The asset management policy can mandate automated alerts for equipment showing signs of wear, reducing unplanned downtime.

5. Sustainability and Circular Economy Practices

Sustainability is a priority for manufacturers, and asset policies must reflect that. Consider the following:

- Guidelines for energy-efficient operation of equipment.

- Policies for recycling, refurbishing, or reusing assets to support circular economy principles.

- Monitoring systems to track carbon emissions from equipment usage.

Why it Matters: A sustainable asset policy meets regulatory requirements and contributes to a greener manufacturing process.

6. Cloud-Based Platforms and Remote Monitoring

Smart manufacturing heavily relies on cloud infrastructure to manage connected systems. The policy should cover:

- How cloud platforms (such as AWS or Azure) will store and analyze operational data.

- Policies for remote access to equipment and monitoring systems for real-time insights.

- Backup and asset disaster recovery protocols to ensure business continuity.

Example: Using cloud-connected sensors, remote teams can monitor machine performance and initiate maintenance from anywhere.

7. Workforce Training and Change Management

A successful asset management policy requires a skilled workforce that understands intelligent technologies. The policy should address:

- Ongoing training programs to familiarize employees with new systems and tools.

- Change management plans to implement new technologies or upgrades smoothly.

- Regular audits and evaluations to assess workforce alignment with asset policies.

Why it Matters: A well-trained workforce effectively manages smart manufacturing assets and minimizes human error.

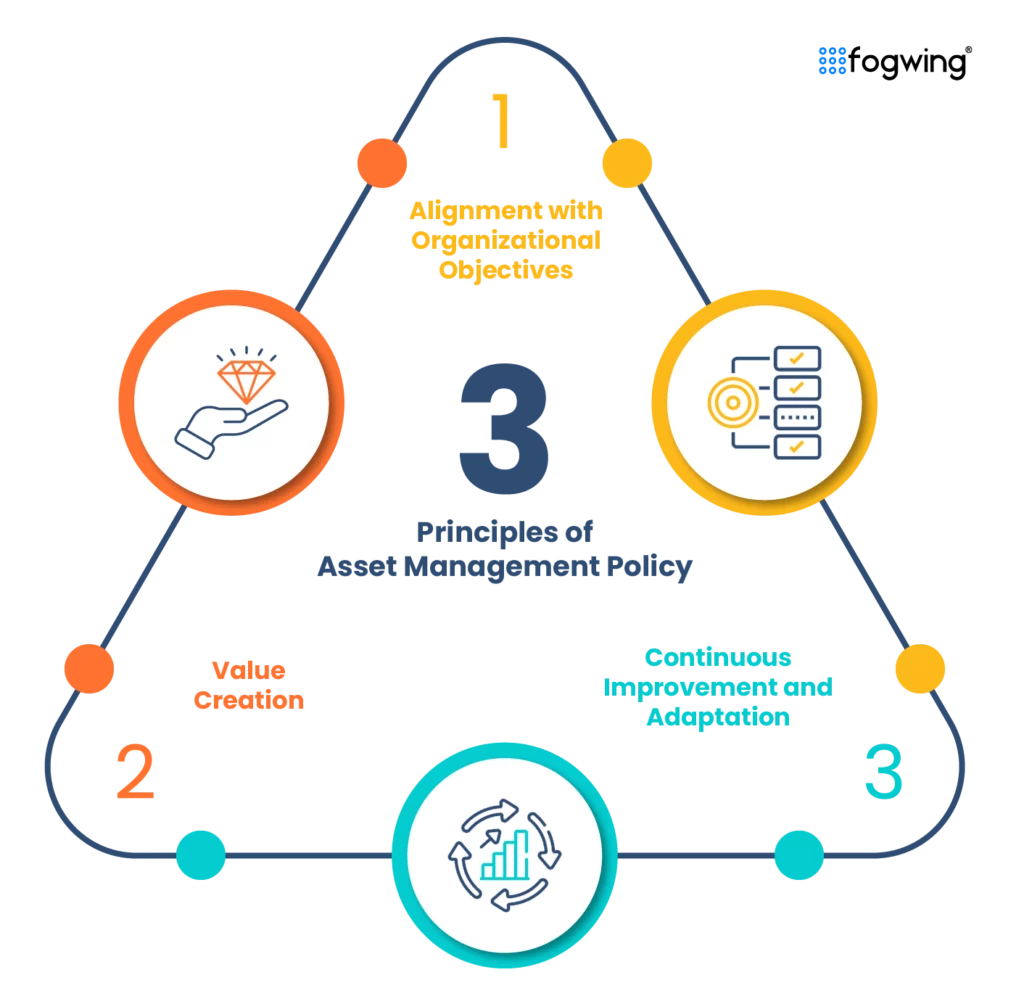

What are the Three Principles of Asset Management Policy?

- Value Creation: In asset management policy, assets must contribute to the organization’s mission and deliver value. In manufacturing, this means leveraging assets for production, generating data insights, and improving decision-making.

- Alignment with Organizational Objectives: Every aspect of asset management should align with broader business goals, such as increased efficiency, sustainability, or innovation. Policies should ensure that assets support both operational needs and long-term growth.

- Continuous Improvement and Adaptation: Asset management policies must be dynamic, allowing continuous improvements based on performance data and evolving technologies. This principle ensures the organization stays competitive by incorporating new tools and strategies like predictive maintenance and data analytics.

The Role of Cloud-Based Platforms in Asset Management Policy

Cloud-based platforms have become essential for modern manufacturing, enabling businesses to monitor, analyze, and manage their assets more effectively. In smart manufacturing, where connected systems and real-time data play a critical role, a management policy that leverages cloud technology ensures asset efficiency, flexibility, and scalability. Below, we explore the fundamental ways cloud-based platforms influence management policy.

1. Centralized Asset Data Management

Cloud platforms enable centralized asset data management, allowing stakeholders across departments to access the latest information. It promotes consistency and reduces the risk of data duplication. Your asset management policy should specify the following:

- What data is stored in the cloud (e.g., performance logs, maintenance history, IoT sensor data).

- Access controls to ensure only authorized personnel can modify critical data.

- Integration with ERP or CMMS systems to consolidate data streams.

Example: Cloud-based CMMS software stores maintenance records and schedules, enabling real-time tracking across multiple facilities.

2. Real-Time Monitoring and Predictive Analytics

Connected assets data management in smart factories continuously generates data processed in the cloud for real-time monitoring and predictive analytics. Your policy should define:

- The frequency of data collection from IoT sensors.

- Guidelines for automated alerts triggered by anomalies or deviations in asset performance.

- How predictive analytics models will inform maintenance schedules.

Why it Matters: Cloud-based predictive analytics can help organizations identify issues before they occur, reducing downtime and maintenance costs.

3. Remote Asset Management and Operational Flexibility

A cloud-enabled asset management system allows for remote asset management and control of assets. It is precious for multi-site operations or when managers must respond to off-site emergencies. Your asset management policy should cover the following:

- Who can access remote systems, and what actions are they authorized to perform?

- Use of mobile applications to manage assets on the go.

- Emergency protocols for remote troubleshooting and intervention.

Example: Managers can log into the CMMS via a mobile app to monitor machine conditions remotely and dispatch technicians, when necessary, through remote asset management.

4. Scalability and Cost Efficiency

Cloud platforms offer scalable infrastructure, allowing businesses to increase or reduce their usage based on changing needs. Your policy should address:

- Guidelines for adding or removing assets in cloud systems to match operational requirements.

- Cost management strategies to optimize cloud usage and avoid unnecessary expenses.

- Service level agreements (SLAs) with cloud providers to ensure uptime and performance.

Why it Matters: Cloud platforms reduce the need for on-premises servers and enhance remote asset management, lowering capital expenses and increasing operational agility.

5. Data Security and Compliance

Security is paramount when managing connected assets via the cloud. The asset management policy outlines the following:

- Encryption protocols for asset data at rest and in transit.

- Multi-factor authentication (MFA) for user access.

- Backup and recovery strategies to prevent asset data loss in cyberattacks or system failures.

Compliance: Your policy must ensure adherence to ISO 55001 and local data protection regulations (e.g., GDPR).

6. Integration with IoT and CMMS Platforms

Cloud platforms are critical in integrating IoT devices and CMMS software to streamline asset management. Integrate Fogwing CMMS, an innovative computerized management software for asset maintenance and management purposes. The policy should include:

- APIs and connectors to link various systems and platforms.

- Procedures for ensuring data synchronization across IoT networks and CMMS tools.

- Reporting frameworks to generate insights from multiple systems in a unified dashboard.

Example: Fogwing CMMS on AWS integrates IoT data from machines to trigger automatic work orders for predictive maintenance.

7. Business Continuity and Disaster Recovery

Cloud platforms provide redundant infrastructure to ensure business continuity during unexpected events. Your asset management policy should specify the following:

- Backup intervals and procedures for data restoration.

- Disaster recovery plans to minimize downtime during outages.

- Procedures for migrating assets to another cloud provider if necessary.

Why it Matters: With cloud-based disaster recovery, businesses can restore operations quickly and avoid disruptions.

Conclusion

A well-defined Asset Management Policy is critical for success in intelligent manufacturing. With the integration of technologies like AI, IoT, cloud platforms, and predictive analytics, managing assets efficiently becomes essential to minimize downtime, control costs, and enhance productivity. The policy aligns asset performance with strategic business goals and ensures risk management, sustainability, and compliance with evolving industry standards.

Integrating Fogwing CMMS—an intelligent computerized maintenance management system—streamlines asset management and maintenance through automated scheduling, predictive insights, and real-time monitoring. By utilizing platforms like Fogwing CMMS, businesses can achieve seamless IT-OT convergence, manage risks proactively, and ensure continuous operations through remote monitoring capabilities.

To thrive in this connected manufacturing landscape, organizations must prioritize seamless integration between IT and OT systems, maintain robust cybersecurity frameworks, and adopt data-driven maintenance strategies.