Manually tracking scheduled maintenance and other asset maintenance-related assignments is impractical in a fast-paced industrial environment, where asset maintenance and production operational efficiency are crucial. Implementing an effective advanced CMMS platform like Fogwing CMMS is essential for ensuring longevity and optimal performance for organizational assets. It offers a seamless solution for conducting industrial maintenance management activities so that equipment and machinery remain in optimal working condition.

Fogwing CMMS, with its cloud-based solution, enables the organization’s maintenance team to track, monitor, and plan maintenance work orders effectively while reducing asset downtime and boosting the operational efficiency of industrial assets. Fogwing CMMS simplifies industry maintenance management with real-time data insights through a user-friendly interface. This comprehensive blog explores how adopting Fogwing CMMS revolutionizes your maintenance strategy and leads to more reliable maintenance operations.

Scheduled Maintenance and its importance

Schedule maintenance refers to a proactive approach to managing asset upkeep. It prevents sudden asset failures and costly downtime by involving pre-planned regular inspections, repairs, and servicing of assets, reducing the likelihood of unexpected downtime. However, managing maintenance schedules can be challenging for the maintenance team, especially while manually juggling between multiple teams and departments. Manual tracking of the assets can lead to maintenance errors, missed schedules, and operational disruptions. It’s where Fogwing CMMS makes a difference.

What is Computerized Maintenance Management Software (CMMS)

CMMS, or computerized maintenance management software, is a platform designed to manage scheduled Maintenance and other activities. The CMMS platform’s ability to centralize the maintenance data, track work orders in real-time, and automate critical tasks makes it the ultimate platform for maintenance management. Manually managing the maintenance can be physically and mentally tiring and might result in missed schedules, poor team management, unplanned downtime, poor communication, and misplacement of essential records. In contrast, Fogwing CMMS simplifies these processes and enables industries to stay proactive with their maintenance activities.

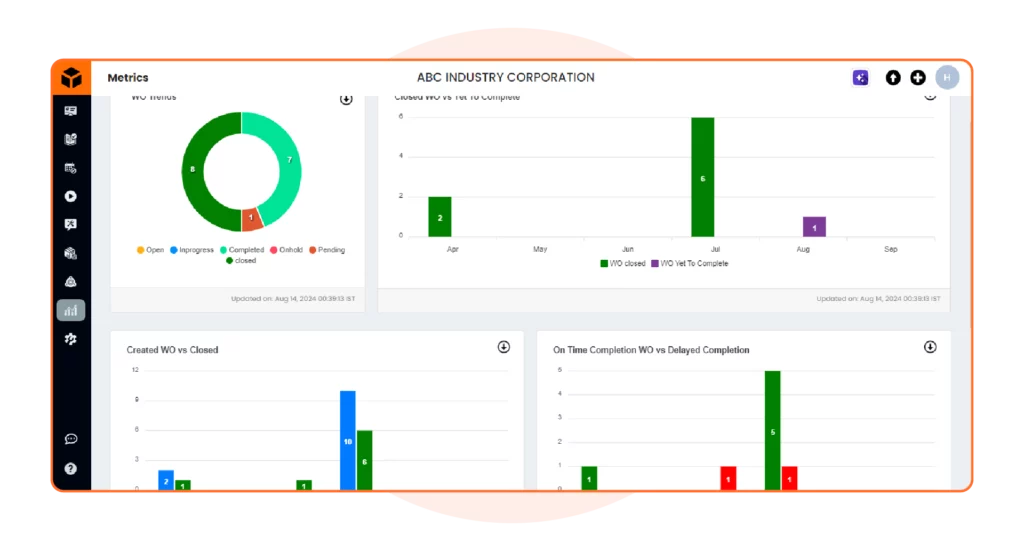

A well-implemented maintenance management software like Fogwing CMMS ensures that assets are maintained regularly, asset breakdowns and downtimes are significantly reduced, and maintenance managers and engineers collaborate well. Its user-friendly interface and scalable features suit industries seeking to enhance their Scheduled maintenance workflows, lower maintenance costs, and ensure long-term asset reliability. Fogwing CMMS also offers comprehensive dashboards and reporting tools, empowering users to make data-driven decisions and optimize maintenance operations.

Why CMMS Matters in Industries:

Reduces Downtime: Regular Maintenance enables businesses to prevent sudden equipment failures that can eventually lead to unplanned downtime; maintenance management by CMMS ensures that production remains uninterrupted, maintenance operations are performed on time, and the operational effectiveness of the assets is maintained.

Enhanced Asset Longevity: Regularly scheduled Maintenance enables businesses to extend asset lifespan. It addresses wear and tear or asset downtime before it becomes a significant issue, helping companies dodge or avoid premature asset replacements.

Enhanced Safety: Adhering to types of scheduled maintenance routines in organizations enhances workplace safety, reducing the risk of accidents on the field. A well-maintained asset or equipment is less likely to malfunction or break, reducing the risk of accidents or injuries to maintenance staff and operators. Maintaining safety regulations and creating a secure workplace are crucial in industries.

Minimizes maintenance cost: In industries that depend on multiple complex and advanced assets or equipment, proactive maintenance management often costs less than reactive repairs. Addressing the asset-related issue before it escalates to a more significant issue enables the business to avoid costly repairs and operational disruptions. It also reduces the maintenance costs associated with reactive repairs.

Streamline Your Maintenance Operations with Fogwing CMMS

Fogwing CMMS provides organizations with a comprehensive intelligent maintenance management solution to manage their maintenance operations and assets. Here’s how it enables businesses to manage their scheduled Maintenance effectively:

Automate Preventive Maintenance: Organizations prefer preventive Maintenance to avoid untimely asset breakdown or downtime. With advanced CMMS software like Fogwing CMMS, you can now automate the scheduling of preventive work orders right under your fingertips. The intelligent system keeps the complete track of the maintenance work orders and automates the entire process. It notifies the maintenance team and manager about the assigned maintenance work order and allows the organization to plan. Plus, you can cancel or pause preventive maintenance work orders if they are no longer required.

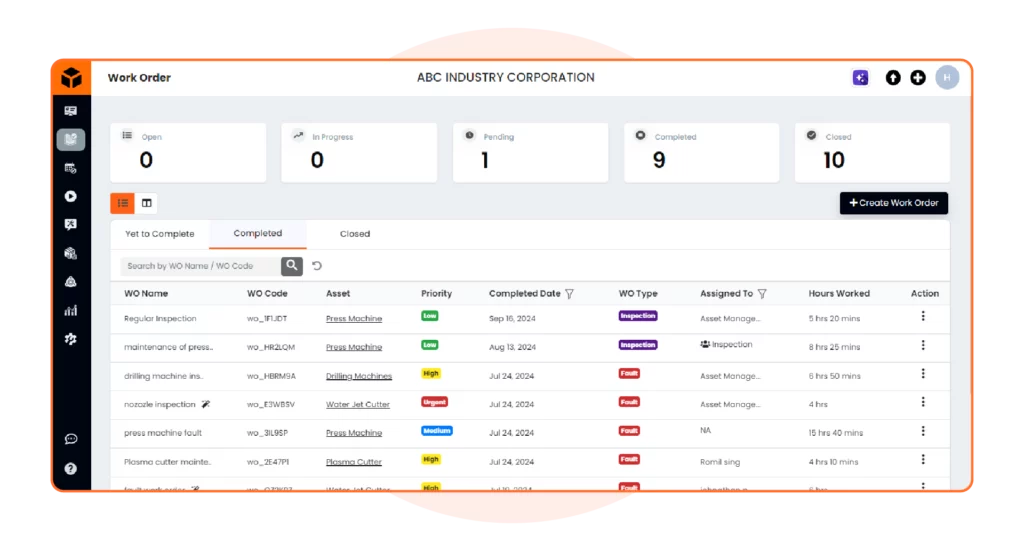

Proactive Scheduling and Assignments: Scheduling maintenance work orders with Fogwing CMMS is proactive and not considered reactive. It enables you to create and assign maintenance work orders ahead of time, just like scheduled Maintenance. It ensures that the maintenance team has complete visibility of the tasks, allowing them to plan their schedules effectively. Due to its cloud-based centralized database, Fogwing CMMS enables the maintenance team to access work orders from anywhere, promoting productivity.

Unlimited Maintenance work order access: With Fogwing CMMS, maintenance managers or supervisors can create an unlimited number of on-demand Maintenance, fault maintenance, inspection, and preventive maintenance orders. This flexibility is essential for business growth and expanding operational needs. Maintenance supervisors or managers can keep track of each work order assigned, ensuring every task is noticed and the order is closed on time.

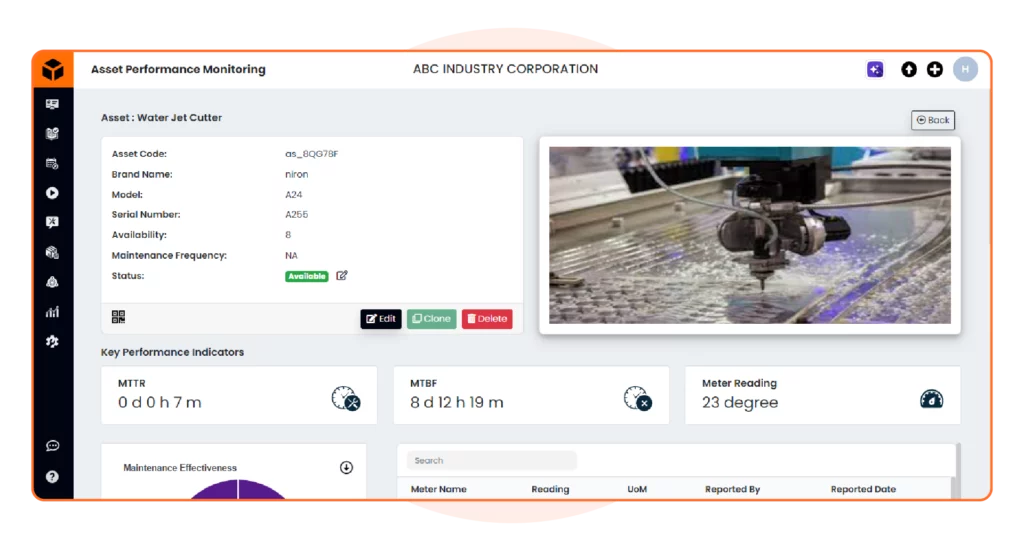

Centralized tracking and Reporting: Advanced maintenance management software like Fogwing CMMS enables the effective monitoring of maintenance work orders. It also helps track assets with your mobile devices. It allows organizations to keep track of detailed maintenance reports, hours worked, and metering data from the field (both IoT and Manually). The centralization of data in scheduled Maintenance makes it easier to monitor ongoing tasks and offers valuable insights to justify the maintenance efficiency.

Manage various kinds of Maintenance: The advantage of utilizing the Fogwing CMMS Platform is that it enables you to track the effectiveness of each maintenance work order. This comparison helps businesses access their maintenance strategies and identify areas for improvement. By keeping On-demand maintenance separate from preventive work orders, the maintenance team can avoid potential issues while responding to unexpected asset breakdowns when necessary.

Comparison between Fogwing CMMS and Manual System

Organizations must adapt to advanced technologies like scheduled Maintenance, the Internet of Things, AI, and many more in changing times. With Industry 4.0 in action, various factories and organizations are turning into smart factories. Relying on the same age-old techniques, such as paper-based logs or spreadsheets, is time-consuming and prone to errors.

Here’s how Fogwing CMMS when compared to manual systems:

- Efficiency: Manual systems require constant updates, follow-ups, and team communication, leading to missed schedules and miscommunication. In contrast, Fogwing CMMS automates scheduling, work orders, and tracking, significantly reducing the risk of human error in maintenance management.

- Collaboration: Due to limited communication tools, field engineers, maintenance managers, and supervisors may need help to align with manual processes and scheduled maintenance schedules. Fogwing CMMS offers real-time updates and asset tracking, allowing team members to access tasks from anywhere and streamlining collaboration.

- Data Tracking: Manually tracking data (such as maintenance reports, hours worked, and performance metrics) is complicated and often requires time. Fogwing CMMS centralizes all maintenance data, making tracking and analyzing performance metrics for continual improvement easy.

Manual systems may suffice for small-scale operations, but as a business grows and asset maintenance becomes more complex, a CMMS like Fogwing becomes essential.

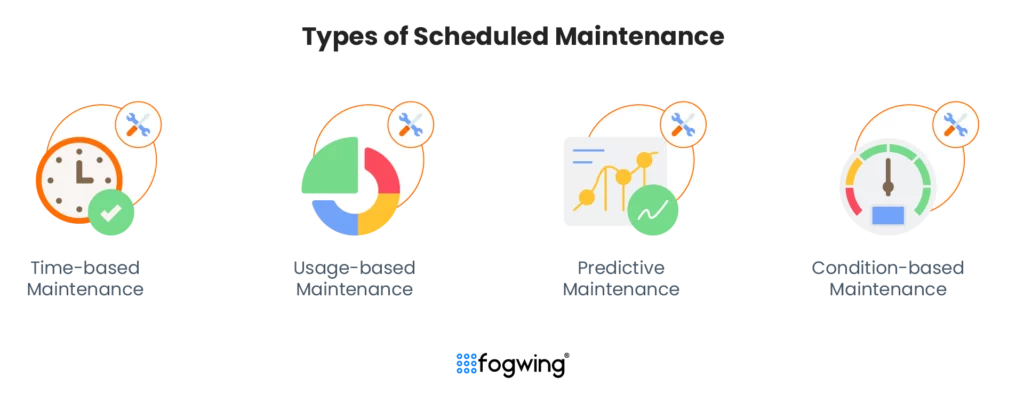

Types of Scheduled Maintenance

Scheduled Maintenance can be categorized into several types, each with its approach and benefits. Here are a few types of scheduled Maintenance:

Time-based Maintenance: Time-based Maintenance involves performing maintenance activities at regular intervals, such as daily, weekly, or monthly. The Maintenance is based on a fixed schedule, irrespective of the asset’s condition.

Usage-Based Maintenance: Asset maintenance is scheduled based on equipment usage metrics, such as the number of operating hours or cycles. This approach ensures Maintenance is performed when the equipment reaches specific usage thresholds.

Predictive Maintenance: Predictive Maintenance is a type of scheduled Maintenance that utilizes data and analytics to predict when an asset might require Maintenance. It aims to perform Maintenance just before equipment is likely to fail.

Condition-based Maintenance: Condition-based Maintenance is scheduled Maintenance in which tasks are scheduled based on the actual condition of the equipment, as determined through monitoring and diagnostics. This approach ensures Maintenance is performed when specific condition indicators signal the need for action.

Can Fogwing CMMS Be Customized for Different Industries?

Absolutely! Fogwing CMMS is highly adaptable and can be customized to meet the unique needs of various industries. Whether in manufacturing, healthcare, utilities, or any other sector that relies on regular planned Maintenance, Fogwing CMMS can be tailored to your specific requirements.

For instance, manufacturing industries may need detailed tracking for machinery and parts. At the same time, healthcare organizations may require a focus on compliance and regulatory reporting. Fogwing CMMS can be configured to handle preventive Maintenance, Planned Maintenance, and on-demand tasks, ensuring that businesses across industries can benefit from a tailored maintenance solution that suits their operational needs.

Get Started with Fogwing CMMS Today

Fogwing CMMS offers a seamless way to manage scheduled Maintenance for your business. From automating preventive maintenance tasks to giving your team access to work schedules from anywhere, your maintenance operations are smooth, efficient, and effective. Say goodbye to manual tracking and scheduling issues—let Fogwing CMMS take care of it all!

Take the next step in optimizing your maintenance management with Fogwing CMMS. Start now to ensure your assets are always in top condition, minimize disruptions, and maximize productivity.

Conclusion

Fogwing CMMS streamlines scheduled maintenance processes by automating tasks, enhancing team collaboration, and centralizing data for easy tracking and analysis. It eliminates the inefficiencies of manual maintenance management, significantly reducing asset downtime and ensuring long-term operational reliability. With its cloud-based platform, businesses can monitor and manage preventive and on-demand maintenance from any location, ensuring optimal equipment performance. The platform’s adaptability suits various industries, allowing customization to specific operational needs. By adopting Fogwing CMMS, companies can boost productivity, lower maintenance costs, and extend asset life, ensuring a smooth and efficient maintenance workflow.