Maintenance and reliability are closely related disciplines that determine how effectively an organization can keep its assets performing at peak levels.

The maintenance management focuses on the maintenance inspection, reactive, repair, and on-demand service requests. However, reliability management emphasizes preventing equipment failures and ensuring consistent asset availability over time.

The maintenance and reliability create a proactive approach that reduces downtime, lowers costs, and maximizes the lifecycle value of critical assets.

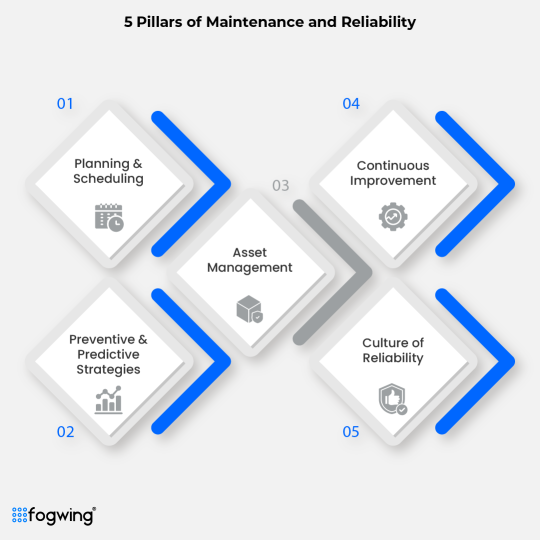

According to the CMRP (Certified Maintenance & Reliability Professional) framework and Society for Maintenance & Reliability Professionals (SMRP), there are 5 Pillars of Maintenance and Reliability:

Pillar 1: Business & Management

The purpose of the business and management pillar is to ensure that maintenance and reliability strategies are aligned with overall business objectives, enabling sustainable value creation, cost control, and operational excellence.

This pillar emphasizes the strategic and financial role of maintenance — moving beyond just “fixing equipment” to becoming a value-driving function.

Key Elements of the Business & Management

1. Strategic Planning

- Define the vision, mission, and long-term objectives of the maintenance organization.

- Develop a maintenance and reliability strategy that supports corporate goals (e.g., uptime, safety, quality, customer satisfaction).

- Align with other departments (operations, finance, HR) to integrate M&R into enterprise strategy.

2. Business Alignment

- Understand how maintenance impacts profitability, asset utilization, and risk mitigation.

- Collaborate with leadership to justify investments in reliability programs, new technology (e.g., CMMS, sensors), or training.

- Develop business cases and ROI models for maintenance initiatives.

3. Performance Measurement

- Define, track, and analyze KPIs and metrics such as:

- Maintenance Cost as % of RAV (Replacement Asset Value)

- OEE (Overall Equipment Effectiveness)

- MTBF (Mean Time Between Failures)

- PM compliance rate

- Use benchmarking and SMRP metrics to evaluate performance and identify gaps.

4. Budgeting and Financial Management

- Prepare annual maintenance budgets based on reliability plans, historical performance, and asset criticality.

- Track actual vs. planned spend on labor, materials, contractors, and projects.

- Forecast cost savings from preventive and predictive maintenance efforts.

5. Resource Management

- Ensure appropriate staffing levels, skill sets, and organizational structure to support the maintenance strategy.

- Develop competency frameworks and training programs to upskill technicians and engineers.

- Integrate with HR for workforce planning and succession management.

6. Policy and Procedure Development

- Establish governance documents, such as maintenance policies, standards, and SOPs.

- Enforce compliance with safety, quality, and environmental regulations.

- Promote a culture of discipline, accountability, and continuous improvement.

7. Leadership and Communication

- Lead cross-functional teams and drive organizational change in maintenance practices.

- Communicate the value of maintenance to executives and stakeholders.

- Promote a reliability culture across the enterprise — not just within the maintenance department.

Example KPIs of Business & Management

| Key Performance Indicator | Purpose |

| Maintenance Cost / RAV Cost | Cost efficiency of maintenance operations |

| PM Completion Rate (%) | Execution of preventive maintenance plans |

| Work Order Backlog (Days) | Maintenance workload management |

| % Planned vs. Reactive | Work Maturity of maintenance practices |

| Asset Utilization | Business impact of equipment performance |

Best Practices of Business & Management

- Align maintenance goals with business KPIs (e.g., production targets, cost per unit).

- Use data-driven decision-making to justify budgets and resource needs.

- Review and refine strategy periodically based on results and changing business needs.

Common Challenges in Business & Management

- Treating maintenance as a cost center rather than a strategic partner.

- Lack of measurable goals or performance indicators.

- Underestimating the financial impact of poor maintenance (e.g., unplanned downtime).

Alignment with Other Pillars

The Business & Management pillar serves as the foundation for the other four:

- It funds and justifies equipment reliability initiatives.

- It guides the work management system based on cost and asset priorities.

- It ensures MRO and procurement practices support business continuity.

- It integrates with operations reliability to balance cost, throughput, and quality.

Pillar 2: Manufacturing Process Reliability

The purpose of manufacturing process reliability is to ensure that maintenance and reliability practices are aligned with production processes to maximize safety, quality, throughput, and cost-efficiency. This pillar emphasizes collaboration between maintenance and operations to eliminate production losses and enhance overall plant performance.

Key Elements of Manufacturing Process Reliability

1. Understanding the Manufacturing Process

- Maintenance teams must understand the core production process, including inputs, workflows, equipment sequences, and output expectations.

- Know how assets contribute to productivity, safety, and quality outcomes.

- Identify critical control points and their impact on equipment and process reliability.

2. Process-Asset Integration

- Map each equipment or asset’s function to the specific steps in the manufacturing process.

- Assess asset criticality not just by value or repair cost, but by its impact on process flow and product quality.

- Collaborate with operations to ensure maintenance schedules and practices support process stability.

3. Support of Continuous Improvement Programs

- Actively participate in Lean, Six Sigma, TPM (Total Productive Maintenance) and other performance improvement initiatives.

- Analyze data related to process downtime, waste, and variability — use maintenance insights to drive improvements.

- Implement Autonomous Maintenance (AM) practices with operators.

4. Downtime Analysis & Elimination

- Track production losses caused by equipment or process inefficiencies.

- Use Root Cause Analysis (RCA) to identify the underlying causes of process disruptions.

- Implement Corrective and Preventive Actions (CAPA) to avoid recurrence.

5. Process Reliability Metrics

Use data to monitor and improve how maintenance supports process efficiency:

| KPIs or Metrics | Purpose |

| Overall Equipment Effectiveness (OEE) | Measures availability, performance, and quality losses |

| Mean Time Between Failures (MTBF) | Indicates reliability of equipment in process |

| Process Downtime (by cause) | Tracks production interruptions due to maintenance or failure |

| Maintenance Impact on Yield | Connects asset performance to product output |

6. Operations-Maintenance Collaboration

- Establish joint teams or councils to align maintenance with production goals.

- Operators and maintenance staff should co-own reliability metrics.

- Encourage early issue detection by operators (first-line inspections, cleaning, and lubrication).

- Train operators to handle basic maintenance tasks — empower them through TPM principles.

7. Process Standardization

- Develop and enforce Standard Operating Procedures (SOPs) that ensure consistent maintenance impact on process conditions.

- Ensure repeatable, safe, and optimized routines for maintenance during operation and shutdown.

Best Practices of Manufacturing Process Reliability

- Integrate maintenance data (work orders, failure logs) with production data (yields, downtime).

- Build a culture of shared ownership of reliability between production and maintenance.

- Use reliability engineering techniques (FMEA, RCA, PM optimization) in collaboration with production engineering.

Common Challenges in Manufacturing Process Reliability

- Treating maintenance and production as separate silos with conflicting goals.

- Overlooking how minor equipment inefficiencies degrade process quality and output.

- Lack of communication and visibility between operations and maintenance planning.

Connection with Other CMRP Pillars

| Related Pillar | How It Connects |

| Equipment Reliability | Process depends on reliable equipment |

| Work Management | Maintenance activities must align with production schedules |

| Business & Management | Reliability supports strategic production targets |

| Procurement & Materials | Parts availability must support process uptime |

Pillar 3: Equipment Reliability

The Equipment Reliability pillar focuses on maximizing asset performance and extending equipment life through engineering practices, data analysis, and reliability-centered maintenance. It emphasizes preventing failures before they happen and continuously improving how assets perform over time.

Key Elements of Equipment Reliability

1. Failure Analysis and Root Cause Elimination

- Conduct Root Cause Analysis (RCA) to identify the origin of equipment failures.

- Use structured methodologies like 5 Whys, Fishbone Diagrams, or Fault Tree Analysis.

- Apply findings to eliminate or mitigate repeat issues.

2. Reliability-Centered Maintenance (RCM)

- Implement RCM principles to determine the most effective maintenance strategy for each asset.

- Classify failure modes and define condition-based, time-based, or run-to-failure tasks.

- Focus on preserving function, not just repairing after failure.

3. Condition Monitoring & Predictive Maintenance

- Use condition monitoring techniques to detect early signs of failure:

- Vibration analysis using sensor and IoT connectivity

- Infrared thermography monitoring for heat analysis

- Oil analysis to measure the oil level in critical piston-based equipments.

- Ultrasonic testing to detect cracks and breaking points in heavy equipments.

- Motor circuit analysis to detect any electronic component failure

- Integrate predictive analytics and AI/ML to forecast failures and schedule interventions.

4. Asset Performance Metrics

Track and analyze equipment reliability using key performance indicators (KPIs):

| Key Performance Indicator / Metrics | Purpose |

| MTBF (Mean Time Between Failures) | Measures asset reliability (higher is better) |

| MTTR (Mean Time to Repair) | Tracks how quickly repairs are completed |

| Availability (%) | Indicates uptime relative to total planned time |

| Failure Rate | Frequency of breakdowns over time |

| OEE (shared with Domain 2) | Measures availability, performance, and quality loss |

5. Design for Reliability (DfR)

- Engage in asset specification and design reviews during capital projects.

- Recommend design changes based on operational history and reliability data.

- Influence equipment selection to improve maintainability, standardization, and lifecycle cost.

6. Criticality and Risk-Based Asset Management

- Use asset criticality analysis to prioritize maintenance resources.

- Assess risk in terms of safety, environment, production loss, and cost.

- Apply FMEA (Failure Modes and Effects Analysis) to prioritize preventive actions.

7. Continuous Improvement

- Implement reliability improvement initiatives across asset classes.

- Use historical data and failure trends to optimize PM schedules, spare parts strategies, and SOPs.

- Collaborate with operations to reduce unnecessary maintenance that doesn’t improve reliability.

Best Practices of Equipment Reliability

- Build and maintain an accurate failure history using a CMMS or APM system.

- Use data-driven decisions to improve maintenance strategy.

- Integrate cross-functional teams (maintenance, engineering, operations) in reliability projects.

- Standardize equipment and parts where possible to reduce variability and increase reliability.

Common Challenges in Equipment Reliability

- Over-reliance on reactive maintenance (“fix it when it breaks”).

- Poor documentation of failure causes and work history.

- Misaligned PM schedules that lead to under- or over-maintenance.

- Not involving maintenance in equipment design or procurement decisions.

Connection with Other CMRP Pillars

| Related Pillar | Relationship |

| Work Management | Work execution impacts failure data quality |

| Manufacturing Process | Equipment reliability drives process reliability |

| Business & Management | Reliable equipment reduces cost and improves ROI |

| Procurement & Materials | Right parts and specifications ensure reliability |

Pillar 4: Work Management

The Work Management pillar focuses on planning, scheduling, executing, and improving maintenance activities to ensure the right work is done on the right assets at the right time with the right resources. It aims to maximize workforce productivity, reduce downtime, and optimize asset performance by implementing structured maintenance processes.

Key Elements of Work Management

1. Work Identification

- Initiation of maintenance work based on:

- Equipment conditions (via inspections or sensors)

- Operator observations

- Scheduled preventive/predictive tasks

- Failure events

- Anyone (operators, technicians, engineers) should be able to initiate a maintenance request through a formal process.

2. Work Planning

- Define scope, materials, tools, labor, and procedures before work execution.

- Ensure job plans are detailed and include:

- Job steps

- Safety requirements

- Estimated duration

- Required skills

- Planners should not perform the work, but prepare everything needed for efficient execution.

3. Work Scheduling

- Assign planned work based on asset availability and workforce capacity.

- Develop weekly and daily schedules, prioritize based on asset criticality and production requirements.

- Coordinate with operations to minimize disruption.

4. Work Execution

- Technicians execute the job as planned, capturing:

- Actual labor hours

- Parts used

- Job notes

- Variances from the plan

- Maintenance should follow standardized work procedures to ensure quality and repeatability.

5. Work Closeout and Feedback

- Technicians complete work orders with detailed notes.

- Supervisors or planners review work completion and validate data quality.

- Feedback is looped back to improve future planning and failure analysis.

6. Backlog Management

- Maintain a backlog of approved but unscheduled work.

- Backlog helps in:

- Prioritizing work

- Balancing resources

- Preventing emergency jobs

7. Use of CMMS (Computerized Maintenance Management System)

- All work orders, asset history, and job plans are documented in CMMS.

- Enables visibility, performance tracking, and compliance.

- Drives reports on KPIs like % Planned Work, Schedule Compliance, and Maintenance Costs.

KPIs of Work Management

| KPIs | Purpose |

| % Planned Work | Measures proactive vs. reactive work |

| Schedule Compliance (%) | Tracks adherence to daily/weekly schedule |

| Wrench Time (Craft Efficiency) | Time technicians spend on actual work vs. waiting |

| Work Order Cycle Time | Duration from request to completion |

| Maintenance Cost per Work Order | Cost effectiveness of execution |

Best Practices of Work Management

- Aim for at least 80–90% of work to be planned and scheduled.

- Use job plans with clear scope, procedures, and safety info.

- Involve operations in scheduling to avoid conflicts.

- Use backlog reports to balance workload and prioritize important jobs.

- Train planners separately from technicians for dedicated planning roles.

Common Challenges in Work Management

The following some of the common challenges team might be facing in the maintenace work management.

- Performing most maintenance reactively.

- Lack of quality job plans or parts availability.

- Technicians skipping documentation during closeout.

- No standardized prioritization process for work requests.

- Misalignment between operations and maintenance schedules.

Connection with Other CMRP Pillars

| Related Pillar | Relationship |

| Equipment Reliability | Structured work reduces failure and improves uptime |

| Manufacturing Process | Effective maintenance supports continuous production flow |

| Business & Management | Efficient work execution reduces cost and enhances ROI |

| Procurement & Materials | Ensures parts availability for timely execution |

Work Management in CMRP ensures maintenance work is well-planned, properly scheduled, and efficiently executed to reduce downtime, control costs, and improve reliability — all while enhancing technician productivity and data accuracy.

Pillar 5: Procurement & Materials Management

This pillar ensures that materials, spare parts, and services are effectively managed to support reliable maintenance execution and asset availability. It covers all aspects from procurement strategy to inventory optimization, supplier relationships, and parts standardization. The goal is to provide the right material, at the right time, at the right cost — without overstocking or stockouts.

Key Elements of Procurement & Materials Management

1. Material Identification and Standardization

- Maintain an accurate catalog of parts with standard naming conventions, classifications, and item codes.

- Avoid duplicates by enforcing naming standards and part hierarchy.

- Collaborate with engineering and OEMs for proper specifications.

- Use BOMs (Bill of Materials) linked to equipment for faster part identification.

2. Inventory Control and Optimization

- Classify inventory using:

- ABC analysis (based on value and consumption)

- Criticality analysis (impact on operations)

- Set appropriate min-max levels, reorder points, and safety stock.

- Track inventory KPIs: turns, stockouts, dead stock, carrying costs.

3. Procurement Strategy

- Develop sourcing strategies for:

- Capital spares

- Routine consumables

- Emergency parts

- Balance cost, lead time, and supplier reliability.

- Engage in strategic sourcing and vendor negotiations to reduce TCO (total cost of ownership).

4. Storeroom and Warehouse Management

- Organize storerooms for quick retrieval:

- Use barcode/RFID systems

- Ensure clean, climate-controlled storage for sensitive parts

- Apply 5S principles for storeroom cleanliness and orderliness.

- Ensure strict issue and return processes with documentation.

5. Parts Availability and Maintenance Planning

- Integrate procurement with maintenance planning and scheduling:

- Check parts availability during job planning

- Auto-generate pick lists or reservations

- Delay work until all parts are ready to avoid job stoppage

6. Vendor and Supplier Relationship Management

- Develop strong relationships with reliable vendors for fast support.

- Evaluate suppliers based on:

- Quality

- Delivery time

- Cost

- Technical support

- Use supplier scorecards to track and improve performance.

7. Obsolescence and Lifecycle Management

- Monitor the lifecycle of parts and manage obsolete or hard-to-find materials.

- Identify alternatives or upgrade plans in advance.

- Avoid emergency purchases due to unplanned obsolescence.

8. Integration with CMMS / ERP

- Link parts master, inventory, procurement, and BOMs within CMMS or ERP systems.

- Use the system to:

- Track usage

- Automate reordering

- Control stock movement

- Align procurement with actual maintenance needs

Key Metrics for Procurement & Materials

| Key Performance Indicators / Metrics | Purpose |

| Inventory Turnover | Ratio Measures how quickly inventory is used or sold |

| Stockout Frequency | Indicates how often critical parts are unavailable |

| Procurement Lead Time | Time taken to receive items after ordering |

| Parts Availability for Scheduled Jobs | % of jobs with all parts available in advance |

| nventory Carrying Cost | Cost of holding stock (space, insurance, aging) |

Best Practices of Procurement & Materials Management

- Use data to forecast parts demand based on maintenance history.

- Implement a just-in-time (JIT) strategy where feasible, balanced with risk.

- Create strategic parts kits for common or recurring jobs.

- Establish critical spare parts policy for high-impact equipment.

- Regularly audit inventory and clean obsolete or redundant stock.

Common Pitfalls of Procurement & Materials Management

- Overstocking non-critical parts that tie up capital.

- Poor storeroom layout leading to wasted technician time.

- Emergency procurement due to lack of planning.

- No coordination between procurement and maintenance teams.

- Inaccurate inventory data in CMMS/ERP.

Connection with Other CMRP Pillars

| Related Pillar | Relationship |

| Work Management | Timely parts availability ensures planned work is executed |

| Equipment Reliability | Quality parts reduce failure risks and extend asset life |

| Business & Management | Inventory optimization improves financial performance |

| Manufacturing Process | Downtime reduction through part readiness improves production |

Procurement and Materials Management in CMRP ensures right-sized, cost-effective inventory and reliable part availability, enabling proactive maintenance, minimizing downtime, and controlling operational costs through strategic sourcing and integrated inventory practices.

How Fogwing CMMS Supports the 5 Pillars of Maintenance and Reliability

Fogwing CMMS software was made with the purpose of addressing the maintenance management challenges based on the best practices defined by the 5 pillars of maintenance and reliability.

1. Planning and Scheduling

Fogwing CMMS simplifies work order creation, assignment, and tracking, ensuring maintenance activities are well-planned and executed on time. With calendar-based scheduling and automated reminders, teams can prioritize tasks, allocate resources effectively, and reduce delays that often lead to unplanned downtime.

2. Preventive and Predictive Strategies

The platform empowers maintenance teams to move from reactive to proactive practices through preventive maintenance schedules and AI-powered predictive analytics. By integrating real-time asset condition monitoring, Fogwing CMMS helps detect anomalies early, allowing for predictive interventions that extend asset life and minimize unexpected failures.

3. Asset Management

Fogwing CMMS centralizes asset information, including performance history, service records, and spare parts availability. This visibility enables informed decision-making on repairs, replacements, and lifecycle costs, ensuring every asset is utilized to its fullest potential.

4. Continuous Improvement

With built-in reporting and analytics, Fogwing CMMS provides actionable insights into maintenance trends, costs, and performance KPIs. These insights allow leaders to identify inefficiencies, refine processes, and drive a culture of continuous improvement across maintenance and reliability functions.

5. Culture of Reliability

Beyond tools and processes, Fogwing CMMS fosters collaboration and accountability by connecting technicians, supervisors, and managers on a single platform. Clear communication, real-time updates, and mobile accessibility empower teams to take ownership of reliability goals and contribute to a culture focused on safe, sustainable, and efficient operations.

Conclusion:

When organizations align these pillars, they move beyond reactive maintenance toward a proactive and reliability-centered approach that maximizes asset performance, minimizes costs, and extends equipment lifespan. Ultimately, investing in these pillars is not just about keeping machines running; it’s about building a sustainable foundation for efficiency, safety, and long-term business success.

FAQ

1. Are the 5 pillars of maintenance and reliability still relevant in Industry 4.0?

Yes. The five pillars of maintenance and reliability — Business & Management, Manufacturing Process Reliability, Equipment Reliability, Work Management, and Materials Management remain highly relevant. What has changed is how they are applied. With Industry 4.0, IoT sensors, predictive analytics, and AI-powered CMMS/EAM software make it easier to measure reliability, predict failures, and manage assets proactively.

2. Which pillar is the hardest to implement on the shop floor?

Work Management is often seen as the toughest pillar because it requires strict planning, scheduling discipline, and collaboration across teams. Materials Management is another challenge, as it demands accurate spare parts forecasting, procurement alignment, and inventory control. Many companies struggle with cultural adoption more than with technology itself.

3. Do small companies need to implement all five pillars?

Not necessarily. Small and mid-sized companies can start with the most impactful pillars—usually Equipment Reliability and Work Management—before scaling into all five. The framework is flexible and can be phased in gradually depending on resources, maturity, and business needs.

4. How do you measure success across the 5 pillars?

Success is measured with key maintenance KPIs, such as:

- MTBF (Mean Time Between Failures)

- MTTR (Mean Time To Repair)

- Planned vs. Reactive Work Ratio

- OEE (Overall Equipment Effectiveness)

- Inventory Turnover

Tracking these metrics helps link reliability improvements to cost savings and operational performance.

5. Is CMMS/EAM software enough to make the 5 pillars work?

CMMS or EAM software provides the digital foundation by centralising maintenance tracking, work orders, asset data, and spare parts management. However, software alone isn’t enough—leadership commitment, skilled teams, and a reliability-focused culture are just as important for sustaining the pillars in practice.