Picture this: You walk into a bustling store filled with satisfied customers, selves perfectly stocked with popular products, and sales are soaring. Sounds like a dream come true. Well, it’s time to turn that dream into reality by analyzing the ins and outs of effective inventory control. This comprehensive guide will explore valuable strategies, industry secrets, and powerful tools to help you optimize your stock levels, minimize costs, and maximize profits. Get ready to unlock the key to efficient supply chain operations as we embark on this journey together!

What is an Inventory Control System?

Inventory control refers to the organized and systematic overseeing a company’s inventory. It includes managing, ordering, tracking, storing, and distributing raw materials, work-in-progress items, and finished products. Maintaining an optimal inventory level to meet customer demand while reducing holding costs and avoiding stockouts or overstock situations is the primary goal of Inventory control management.

Effective inventory management involves consistently balancing the supply and demand for different items to prevent stockouts or overstocking. This process enables businesses to make informed purchasing, production, and sales decisions to maintain an optimal inventory level.

The primary goal of this process is to strike a balance between ensuring the stock availability to satisfy customer demands while minimizing the overall cost associated with storing excess inventory. It requires careful planning and management, as an uneven list can adversely affect an organization’s profitability.

An organization achieves effective inventory control by involving advanced systems and procedures for tracking inventory levels. It also consists of specialized software programs designed for this purpose or even manual recording methods such as spreadsheets.

Why is Inventory Control Management Important?

Having a hold of your inventory is crucial for any business operations, regardless of its size or industry. It refers to managing and monitoring the organization’s stock levels to ensure it meets customer demand while minimizing costs. Implementing proper inventory control in organizations enables the business to balance optimal stock levels to meet demand while reducing financial risks.

Here are a few factors that explain why inventory control management is essential for your business and how it can positively influence your organization’s overall success.

1.Avoids Stock Shortages:

Inventory control is paramount in preventing stock shortages. When you have insufficient stock, your chances of disappointing your customers rise.

By implementing robust inventory control management strategies, businesses ensure that organizations have adequate supplies in their inventories, which will help them meet customer demands.

By constantly tracking stock levels, reorder points, and lead times and accurately predicting demand, organizations can ensure that you always have enough stock to help you meet customer demands.

This foresight enables timely replenishment, averting disruptions in the supply chains and maintaining seamless operations. Additionally, employing technologies like automated replenishment systems and real-time tracking with the Fogwing Asset+ platform further fortifies this protection against stockouts, safeguarding customer satisfaction and business continuity.

Effective inventory control is a vigilant guardian, ensuring products are always available with the Fogwing Asset+ platform when needed.

2. Minimize Storage Cost:

Sometimes, overstocking can also be determined to your bottom line as it results in increased storage costs. So, businesses can optimize warehouse space by accurately monitoring stock levels and turnover rates.

The inventory control method prevents overstocking, which leads to minimized inventory storage costs. Moreover, it aids in identifying slow-moving items that may be occupying valuable space unnecessarily.

Implementing lean inventory practices and adopting technology-driven solutions for deemed forecasting and order optimization further contribute to cost savings. Implementing inventory practices and adopting technology-driven solutions for demand forecasting and other optimization further contributes to cost savings.

By strategically managing inventory, businesses can allocate resources more effectively, reducing the financial burden associated with excess storage. In essence, streamlined inventory control is crucial in maximizing cost-efficiency within the supply chain.

3. Reduce the risk of outdated stock: An obsolete inventory refers to supplies that cannot be sold or used due to changes in demand, technology advancements, or other factors. A well-managed inventory system significantly reduces the risk of outdated stock. By closely monitoring product shelf life and turnover, businesses can identify inventory before it becomes obsolete. It enables timely adjustments in procurement and marketing strategies.

Additionally, employing technologies like automated tracking and implementing first-in, first-out practices ensures that older stock is solid or utilized first. This proactive approach minimizes the financial impact of holding outdated goods, safeguarding profitability and brand reputation. An effective inventory control method is a buffer against the risks associated with aging or obsolete stocks.

4. Improves Cash Flows: Efficient inventory control leads to better organizational cash flow management. When you hold excess inventory, your cash flow is tied up and may depreciate. It enables the business to allocate resources more effectively and invest in other vital areas of operation.

Additionally, accurate demand forecasting and timely restocking prevent overstocking, freeing up money that would otherwise be tied to surplus inventory. Streamlined inventory turnover also ensures the prompt generation of revenue and sales of products. An effective inventory control method optimizes fund flow dynamics, providing businesses greater financial flexibility and stability.

5. Enables Better Decision-Making:

Accurate inventory control facilitates better decision-making. Precise and up-to-date data on stock levels, turnover rates, and product demand empowers businesses to make informed decisions about procurement, production, and marketing strategies. It enables managers to identify trends, adjust ordering, and optimize reorder points.

Additionally, real-time tracking and reporting capabilities provide valuable insights into inventory performance. Inventory control services reduce the guesswork and minimize the risk of overstocking or stockouts. So, effective inventory management is a critical tool for making more thoughtful and strategic decisions.

Types of Inventory Control System

Inventory management lies at the heart of a well-functioning supply chain, ensuring businesses meet customer demands while minimizing carrying costs. Various inventory control systems have emerged to achieve a balance between price and customer demand. Each inventory is tailored to specific operational needs and industries.

From perpetual systems that offer real-time visibility to periodic approaches that rely on scheduled checks, understanding these different systems is pivotal for businesses striving for operational excellence. Several inventory control systems are available today, each designed to suit various business needs.

This section will talk about some commonly used types of inventory control systems and their functionalities:

1. Perpetual Inventory System:

The perpetual inventory control system is an automated approach used by most businesses for managing their inventory levels. It continuously tracks the organization’s stock by leveraging cutting-edge technology such as barcodes or RFID. It ensures a constant real-time watch over inventory levels.

This precision grants businesses unparalleled insights into their stock, enabling them to make timely and informed decisions. Widely embraced in the dynamic realms of retail and e-commerce, the perpetual inventory system is a cornerstone for maintaining accuracy, optimizing operations, and meeting customer demands with unmatched efficiency.

The seamless technology integration into inventory control sets a new standard for precision and control in today’s fast-paced business landscape.

2. Periodic Inventory System:

The Periodic Inventory system works differently from the perpetual system since it does not keep track of ongoing stock level changes but focuses on regular physical counts. A periodic review system provides a structured approach to the inventory control system.

The business assesses its stock levels at defined intervals and initiates replenishment orders accordingly. While straightforward, this system demands careful planning to avoid potential stockouts, particularly when demand experiences unforeseen fluctuations.

Striking the proper balance between cost-effective inventory control levels and meeting customer needs is crucial. This method provides value for businesses with stable demand patterns, offering a pragmatic way to manage their inventory without the complexities of real-time tracking systems.

3. Just-In-Time Inventory System:

The just-in-time inventory control system minimizes excess inventory by reducing waste and maximizing efficiency. In this system, the products are ordered and received as needed for production or to meet customer demands. By synchronizing supply with demand, businesses can reduce the carrying costs of storing excess inventory.

JIT requires a high-efficiency supply chain, reliable production schedules, and dependable suppliers to ensure products arrive according to the requirements when needed in industries where precision and efficiency are paramount, such as manufacturing and retail.

4. ABC Analysis:

ABC Analysis is a strategic classification method that segregates inventory into three tiers of importance: A, B, and C. Category A comprises high-value items, B encompasses medium-value goods, and C includes low-value products.

This inventory control system proves invaluable in directing resources and focus toward the most critical items. By prioritizing Category-A, businesses ensure that high-value assets receive the utmost attention and investment. Category B items, while significant, require a balanced approach.

Being lower in value, Category-C undergoes a more streamlined management process. ABC Analysis equips businesses with a powerful tool for optimizing inventory strategies, ultimately enhancing operational efficiency.

5. FIFO and LIFO Methods:

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are two prominent methods for valuing inventory control and determining the cost of goods sold (COGS) in accounting. FIFO operates on the premise that the first items purchased are the first to be sold.

This inventory control method is well-suited for businesses dealing with perishable goods or those subject to price fluctuations, as it tends to yield higher reported profits during inflationary periods. Conversely, LIFO assumes that the most recently acquired items are the first to be sold.

This method is advantageous for businesses that reduce taxable income during rising costs, as it typically results in lower reported profits. Both methods have distinct financial implications, and the choice between FIFO and LIFO can significantly impact a company’s financial statements and tax liabilities.

Hence, it’s essential for businesses to carefully evaluate their specific circumstances before selecting a method.

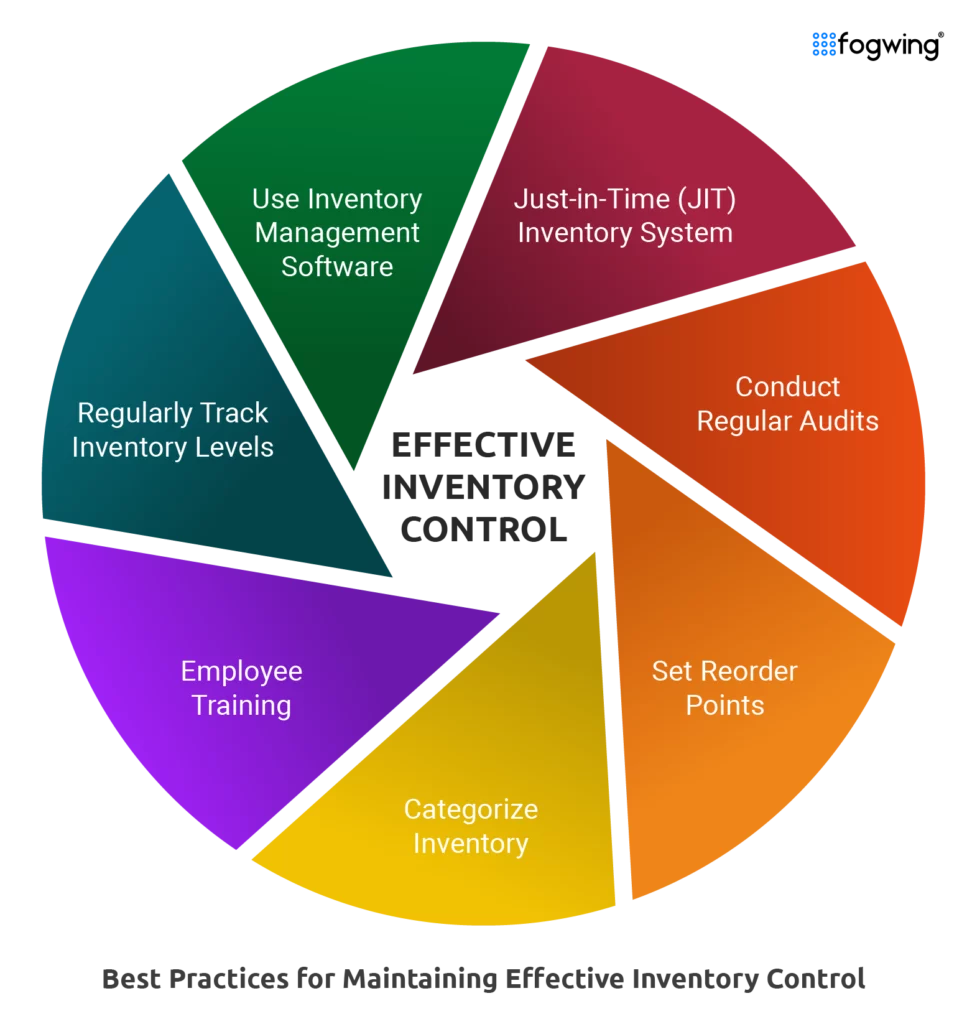

Best Practices for Maintaining Effective Inventory Control

Inventory control methods are an essential aspect of running a successful business. It involves managing and tracking the quantity, location, and movement of all inventory items to ensure that the right products are available at the right time for customers.

With an efficient inventory control system, businesses can avoid overstocking items that may not sell or understocking popular products, resulting in lost sales and dissatisfied customers.

While managing parts inventories, it is essential to implement best practices that help streamline their processes and optimize inventory levels. This section will discuss some of these best practices in detail.

1. Regularly Track Inventory Levels: The first step towards maintaining effective inventory control is consistently tracking your inventory levels. It means keeping a close eye on which items are selling quickly and moving slowly. By regularly monitoring your stock levels, you can identify patterns and make more informed decisions based on restocking or discontinuing certain products.

2. Use Inventory Management Software: Manual inventory tracking methods have become outdated with technological advancements. Invest in reliable inventory management software to track and manage real-time stock levels to maintain efficient inventory control objectives. It will preserve time and reduce the chances of human error.

3. Implement Just-in-Time (JIT) Inventory System: JIT is a popular technique used by many successful businesses as it allows them to keep their stock levels at an optimal level by ordering just enough stock to meet customer demand without holding excess products. This method helps reduce storage costs and minimizes the risk of overstocking.

4. Conduct Regular Audits: Regular audits are crucial for maintaining efficient inventory control. These include physical stock checks to ensure that the quantity of items recorded in your system matches the actual stock on hand. Audits also help identify any discrepancies or potential issues with inventory management processes.

5. Set Reorder Points: Reorder points specify the inventory level where the new orders are placed to avoid running out of stock. Businesses can ensure sufficient supply without excess inventory by setting reorder points, saving storage space and costs.

6. Categorize Inventory: Categorizing inventory into different groups based on demand, lead time, and profitability can help make more accurate restocking decisions. For example, high-demand products may need to be restocked more frequently. In contrast, slow-moving items may require a more minor replenishment cycle.

7. Train Employees on Proper Inventory Management Procedures: Efficient inventory control is only possible with well-trained employees. Ensure your staff is familiar with inventory management procedures and accurately tracking and managing stock levels. It will minimize errors and ensure consistency in inventory control techniques.

Maintaining efficient inventory management requires continuous effort and attention. By following these best practices, businesses can better manage inventory levels, reduce costs, and enhance customer satisfaction.

CMMS Software that helps with Inventory Control Management

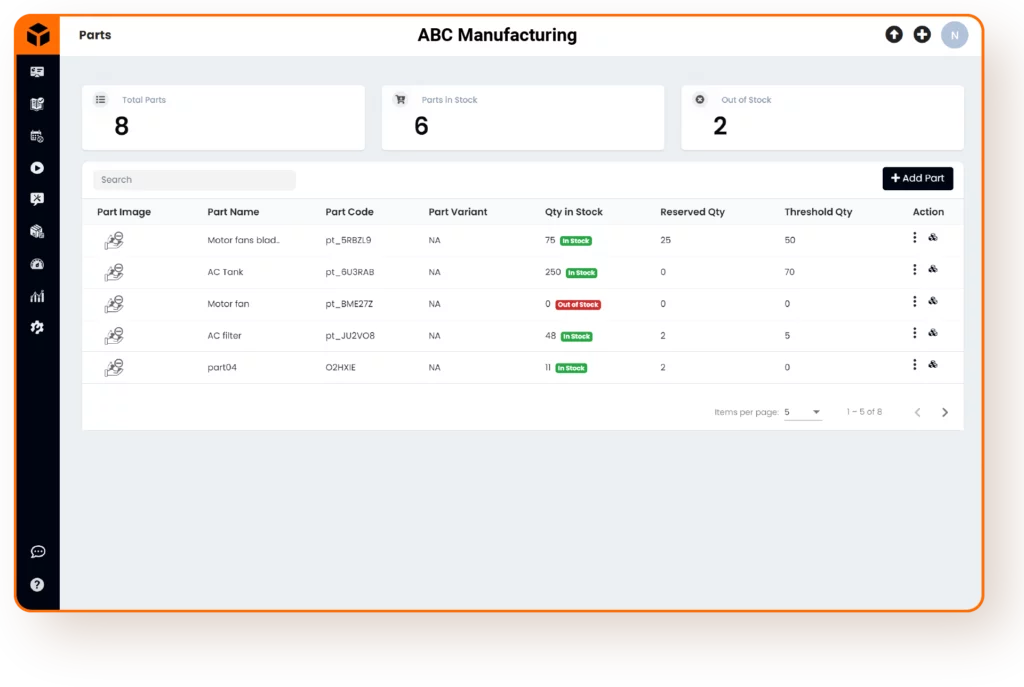

Fogwing Asset+ offers robust features that significantly enhance your inventory control management processes. Availability of materials and parts is critical to completing the maintenance requests on time.

The Fogwing Asset+ CMMS software simplifies it through inbuilt inventory management functions.

1. Real-Time Visibility: Asset+ provides real-time insights into your inventory levels, enabling you to monitor stock movements, identify trends, and promptly respond to changes in demand. It allows organizations to create and manage a list of materials and parts-related information, variations, quality, and available locations in one place for quick access.

2. Automated Tracking: Utilizing technologies like RFID and barcodes, Asset+ automates the tracking of inventory items, reducing the likelihood of errors, ensuring accurate and efficient stock management, and effectively managing inventory control. It also keeps track of the cost against work orders to calculate the overall maintenance cost accurately.

3. Customizable Data Fields: The platform allows you to define custom fields for your inventory items, accommodating unique characteristics crucial to your manufacturing process that might not be covered in standard forms. It will enable the maintenance engineers to reserve the parts against the work -order for on-time completion.

4. Mobile App Integration: Asset+ extends its functionality to a mobile app, allowing you to manage and monitor inventory on the go, providing flexibility and real-time decision-making capabilities while enhancing inventory control objectives.

Conclusion

Effective inventory control is crucial for any business that deals with physical products. It ensures accurate tracking and management of goods, helps streamline operations, and reduces unnecessary costs. By implementing the tips discussed in this blog, such as using technology, forecasting demand, and setting up safety stock levels, businesses can achieve efficient inventory control services and ultimately improve their bottom line.

By leveraging Advanced inventory features, Fogwing Asset+ empowers enterprises to optimize inventory control, streamline processes, and make informed decisions, ultimately contributing to increased operational efficiency and improved overall performance. So, take some time to evaluate your current inventory practices and make necessary changes to reap the benefits of effective inventory control.