Work Order Management means managing the production operation process, including preparing plans, allocating, and assigning jobs to operators or supervisors to complete the finished goods order. Generally, work orders start as a request to begin producing an item by creating each production process or stage as a work order. The production work order or job order specifies what the production team will produce, the quantity they need to make, and the expected completion date.

Work order also includes information on which raw materials to consume and which process to follow while manufacturing an item. Work order management in manufacturing documents the entire manufacturing process and operating procedure for consistency. It provides all the necessary information to complete a task, such as material requirements, allocation, operator assignment, machine utilization time, quality production, etc.

What is a Work Order Management System?

A work order management system is the digital representation of production process management in a manufacturing organization. It provides a tool to capture from customer orders to the delivery of the finished product. A work order management system or software quickly and accurately calculates the resources needed to complete a manufacturing process, including expected time, costs, and machine availability, and also enables tracking of the manufacturing progress.

The work order management system could be part of the Enterprise Resource Planning, Manufacturing Resource Planning, or Manufacturing Execution System.

What is the difference between Order Management and Work Order Management Systems?

An order management system, or OMS, is a software-based system that enables the management to capture customer orders, such as sales orders and their entire lifecycle. It allows the business to track all the operational information and processes, including customer or sales order entry, inventory management, resource allocation, order fulfillment, and more. Hence an Order Management System is a primary system for the corporate organization.

A new work order management system offers high-end and real-time visibility into the complete inventory and the order progress. It ensures that the customers are receiving orders on the expected timeline.

However, it generally covers the internal work process to meet the customer’s sales order. Work or job orders are the factory order to produce the product based on the customer’s sales order. Typically customer sales orders could capture one or more product orders; however, a manufacturing work order refers to only one item.

Why is Work Order Management System important in manufacturing?

Businesses increasingly implement Industry 4.0 practices and rely on intelligent manufacturing to keep up with the digitalized world. Work order management is critical in manufacturing, and various methods are available to automate each part.

A highly efficient work order management application or system has numerous benefits for manufacturing and helps avoid high operating costs and excess time spent on manual work. It also digitalizes the production progress, the quality of productions, rejection, or scraps for a given manufacturing or sales order. A work order management system helps streamline the production process; hence it is critical in manufacturing operations.

Types of Work Orders in Manufacturing

Typically, work orders or job order process varies in manufacturing industries depending on the type of goods produced. The Automotive and OEM industry follows the assembling process through parent and child work orders. However, pharma and food processing industries follow a recipe approach to the production process with various stages of ingredients.

In manufacturing, the types of work orders can vary depending on the specific processes and requirements of the industry. Here are some common types of work orders in manufacturing:

- Production Work Orders: These work orders are used to initiate and track the production of a specific quantity of a product. They include product specifications, quantity, required materials, and production schedule.

- Maintenance Work Orders: Maintenance work orders are used to schedule and track maintenance activities for equipment, machinery, or facilities. They can include preventive maintenance tasks, repairs, inspections, or equipment servicing.

- Repair Work Orders: Repair work orders are specifically created to address equipment or product defects, malfunctions, or breakdowns. They focus on identifying and resolving issues to restore functionality.

- Change Order or Engineering Change Orders (ECOs): Change orders are used to document and track changes to product design, specifications, or processes. ECOs are typically initiated to implement engineering changes, improvements, or modifications to existing products or manufacturing processes.

- Service Work Orders: Service work orders are relevant in manufacturing scenarios where customer service or maintenance activities are provided. They outline the service requirements, scope of work, and customer-specific instructions.

- Material Request Work Orders: These work orders are generated to request and track the procurement or transfer of materials needed for manufacturing processes. They ensure proper inventory management and timely availability of materials.

- Inspection Work Orders: Inspection work orders are created to conduct quality inspections, audits, or tests on finished products, work in progress, or incoming materials. They help ensure compliance with quality standards and identify any non-conformities.

It’s important to note that the specific types of work orders used in manufacturing can vary depending on the industry, company, and unique operational requirements.

What are the benefits of a work order management system?

A work order management system’s primary benefit is digitizing the entire production process in the computerized system for efficiency. However, the are other benefits that add more value to the business.

Streamline Production Process

Digitizing the entire production process in a work order management system helps identify immaturity and streamline the execution process more consciously.

Production Visibility

With the help of operator entry in real-time, work order status, quality produced, and rejection level across the factory floor provides overall visibility of entire production operations to identify the improvement areas.

Effective Planning and Execution

Machine availability and prioritization are crucial to plan the production operations on that day. A real-time report from the factory floor allows planning the subsequent production planning and execution efficiently.

Forecasting

Upcoming machine maintenance, material availability, and supervision are critical to preparing production planning. Work order management software provides real-time visibility to plan production operations based on the above constraint.

Agile Production Operation

During the day of operations, the sudden situation on the factory floor could enforce a plan change for the rest of the period. High visibility on the shop floor and tracking work orders help plant managers and supervisors to change the course of execution more efficiently.

How to do work order management using SFactrix MES Software?

Work order management is SFactrix MES Software’s core module to optimize production process efficiency.

SFactrix is an IoT-integrated Smart Manufacturing Execution System that helps manufacturers to digitalize production planning and execution and automate factory floor operations. It is truly a one-stop MES solution for complete factory digitalization.

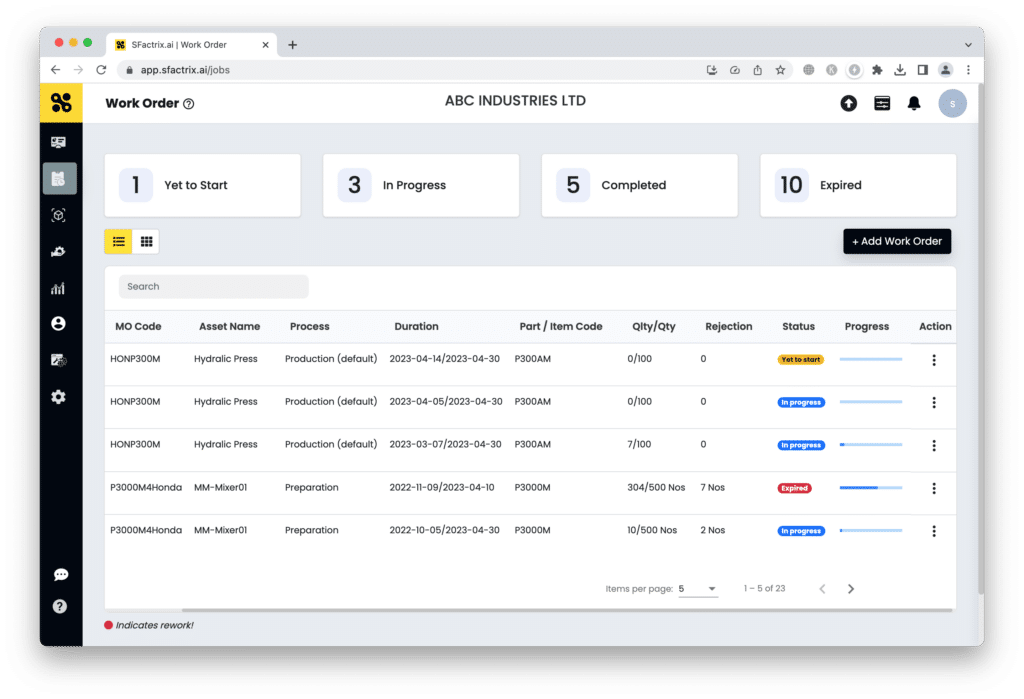

SFactrix.ai allows the creation of work orders against each manufacturing or sales order digitally. It enables tracking the progress of production work orders in real time.

Work order management primarily helps organizations assign tasks or jobs to operators and track the extent of the manufacturing work orders in real time to estimate the overall delivery time. The digitalized work order management feature in SFactrix prevents human errors in manual entries of customer orders and avoids the tedious process of maintaining work ledgers.

SFactrix MES Software’s Work Order Management module offers the following functions:

- Allows to create parent and child work orders and assign them to respective machine/operators for execution

- Allows to capture the progress of each work order, quantity produced, rejections, and accomplishment through shift reports.

- Keep track of each work order’s efficiency to plan upcoming manufacturing order executions.

Leveraging the SFactrix cloud MES solution helps manufacturers to optimize their entire production process. The advanced features of SFactrix MES help manufacturers improve productivity and reduce the total manufacturing cycle time. SFactrix Smart MES solution is user-friendly, requiring no technical skills, no download or installation. It is cost-effective and requires no upfront investment.

Conclusion:

Implementing an SFactrix MES with a work order management system helps manufacturers digitalize the production process and execution. Not only does it save much time, but it can also increase the availability and performance of equipment and boost employee productivity and machines’ efficiency. Businesses become much more efficient, and the production line becomes more optimized.