What is Industry 4.0 Maturity?

Industry 4.0 maturity model is a quantifiable measurement to assess the impacts of transformation in business operations and maturity. Industry 4.0 transforms the business from traditional to digital operations for high visibility, transparency, and efficiency. The new world of digital technologies such as IoT, AI, Edge, and Cloud Computing is the foundation for industrial transformation. But transformation is not just about technology; it is a perfect blend of people adoption, process alignment, and technology advancement.

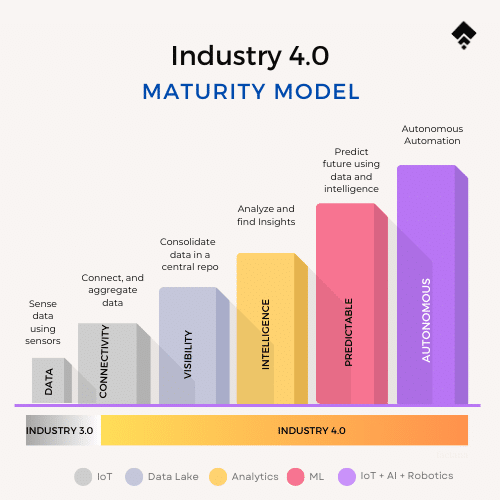

Reaching the ultimate value of Industry 4.0 requires an incremental transformation approach to reach the highest Industry 4.0 maturity model. Below diagram provides a reference model of 5 stages of maturity.

Stage 1 Start with Asset Connectivity.

The first step towards Industry 4.0 is bridging the gap between the physical and digital worlds. The industry context is about integrating OT (Operational Technology) and IT (Information Technology). The Internet of Things helps connect your machines, sensor, PLCs, and SCADA systems with enterprise systems, applications, and infrastructure through the IoT Platform. IoT Gateway and Edge Devices help to eliminate unwanted data from machines and get cleansed data for data processing.

Stage 2 Consolidate data to access from anywhere / anytime.

The traditional data aggregation and historian approach at the factory floor (on-premise) limits the data accessibility, visibility, and insights within the premises. Decision makers accessing these data requires manual efforts and delays, leading to poor planning and timely business optimization. With the power of cloud computing, business users can compile machine data, business systems, and other events that can consolidate on the cloud for faster processing and high visibility. Data-warehouse, DataLake, or Lighthouse are classic technology available for industrial data consolidation.

Stage 2 of the industry 4.0 maturity model is to connect and consolidate data accessible from anywhere and anytime.

Stage 3 Perform analysis to understand” what happened”

When every data gathered from the factory is available on the cloud, it is time to analyze the data to extract more meaningful insights and intelligence to guide the business users. The value of industry 4.0 is all about data-driven business insights and intelligence that help decision-makers align and optimize business operations for higher profitability. Manufacturing intelligence solutions deliver key performance indicators such as OEE, TEEP, Time Loss, and Takt value, which drive factory leaders to improve floor operations.

Stage 4 Predict to understand “what will happen in the future”

Predicting the future is always a dream for everyone, including business leaders. Especially when you have a technology that can help us to predict “What will happen near future,” you have the most excellent tool to plan your future. Artificial Intelligence and Machine Learning are modern tools that will help industry leaders predict upcoming challenges and issues based on the data gathered. The fourth step of the industry 4.0 maturity is to leverage the data to train the ML model to predict machine maintenance, quality issues, demand trend analysis, supply chain roadblocks, and operational downtime.

Stage 4 of the industry 4.0 maturity model is to predict the future using the data gathered from the operational technology environment.

Stage 5 Train machines to act autonomously “when it happens”

Industrial automation happens during the period of Industry 3.0. Though robotics automation helps to reduce human efforts, high volume, and production, it is accessible and controllable at the factory level. In the current digital era and internet world, there is a demand to modernize the factory to operate autonomously to meet global markets. While we leverage IoT, AI, and ML technologies to predict factory futures, they can use to build autonomous operations by integrating with existing automation systems. This opportunity leads the industry to Industry 5.0, an ultimate state of maturity in digital transformation.

Conclusion

As we started, Industry 4.0 is the new norm that drives the industry to the digital world. Today’s deep technologies help business leaders accelerate the transformation journey. It is essential to consider the maturity path for adopting digital operations. Industry 4.0 implementation requires expert advice before investing. According to Gartner research shows that 80% of CEOs are increasing digital technology investments to counter current economic pressures, including inflation, scarce talent and supply constraints

FAQs

1. What is the Industry 4.0 Maturity Model?

The Industry 4.0 Maturity Model is a framework that measures the level of digital transformation in industrial operations. It evaluates how effectively a company integrates digital technologies like IoT, AI, edge, and cloud computing to achieve visibility, efficiency, and autonomous operations

2. What are the 5 stages of Industry 4.0 maturity?

The 5 stages of Industry 4.0 maturity are:

- Asset Connectivity – Connecting machines and devices using IoT.

- Data Consolidation – Centralizing data via cloud platforms for access anytime, anywhere.

- Descriptive Analytics – Analyzing data to understand past performance.

- Predictive Analytics – Using AI/ML to forecast future events.

- Autonomous Operations – Training machines to act independently using intelligent systems.

3. How can companies start their Industry 4.0 journey?

Companies can start by connecting assets via IoT and building a data infrastructure. Consulting experts for a tailored maturity roadmap is also recommended before making major investments

4. What technologies enable Industry 4.0 transformation?

Key technologies include the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), Edge Computing, and Cloud Platforms.