Managing maintenance operations in today’s fast-paced manufacturing environment is crucial. The Computerized Maintenance Management System or CMMS Software for Manufacturing can streamline processes, reduce downtime, and improve asset reliability.

With many CMMS providers available, choosing the right Computerized Maintenance Management System (CMMS) for manufacturing asset maintenance requires deeper comparison and analysis.

This blog will walk you through key considerations, features, and best practices to ensure you choose the perfect CMMS solution to drive operational success and achieve your business goals.

Why manufacturing business need CMMS Software

Manufacturing businesses operate in a highly competitive environment where asset reliability and operational efficiency are crucial for maintaining productivity and profitability. Unplanned equipment breakdowns and inefficient maintenance processes can lead to costly downtime and production delays.

According to a study by Aberdeen Research, the average cost of unplanned downtime in manufacturing is approximately $260,000 per hour.

This is where CMMS (Computerized Maintenance Management System) software becomes essential. CMMS helps manufacturing companies streamline maintenance operations by scheduling preventive maintenance, tracking work orders, and managing spare parts inventory.

Offering real-time insights into asset performance enables proactive decision-making, minimizes unplanned outages, and extends the lifespan of critical equipment.

With CMMS software, manufacturers can achieve higher operational efficiency, reduce maintenance costs, and maintain a competitive edge in the market.

How to find a CMMS Software for Manufacturing Business?

Before selecting a CMMS for Manufacturing, you must thoroughly understand the specific needs of your manufacturing operations. A precise evaluation of your maintenance requirements will guide you toward the most suitable solution and ensure seamless integration into your workflows.

Start by identifying your most frequent maintenance challenges. For example,

- are unplanned equipment failures causing downtime?

- Or are delayed maintenance schedules resulting in inefficiencies?

Understanding these pain points helps you prioritize preventive maintenance, automated alerts, task scheduling features, and selecting the best CMMS for manufacturing.

Next, evaluate the scope of your asset management. How many machines, tools, and facilities need to be maintained?

Whether managing a few critical assets or a large, complex inventory, choosing a scalable CMMS ensures it grows alongside your operations.

Consider mobility requirements for your technicians. Suppose your team works across multiple locations or needs real-time access to maintenance data. In that case, a CMMS with mobile functionality can improve communication, reduce delays, and enable faster decision-making.

Finally, determine the level of reporting and analytics required. Do you need basic metrics, or are you looking for detailed insights to optimize maintenance strategies, track asset performance, and reduce costs?

These questions will support you in creating a roadmap to identify the right CMMS for manufacturing needs.

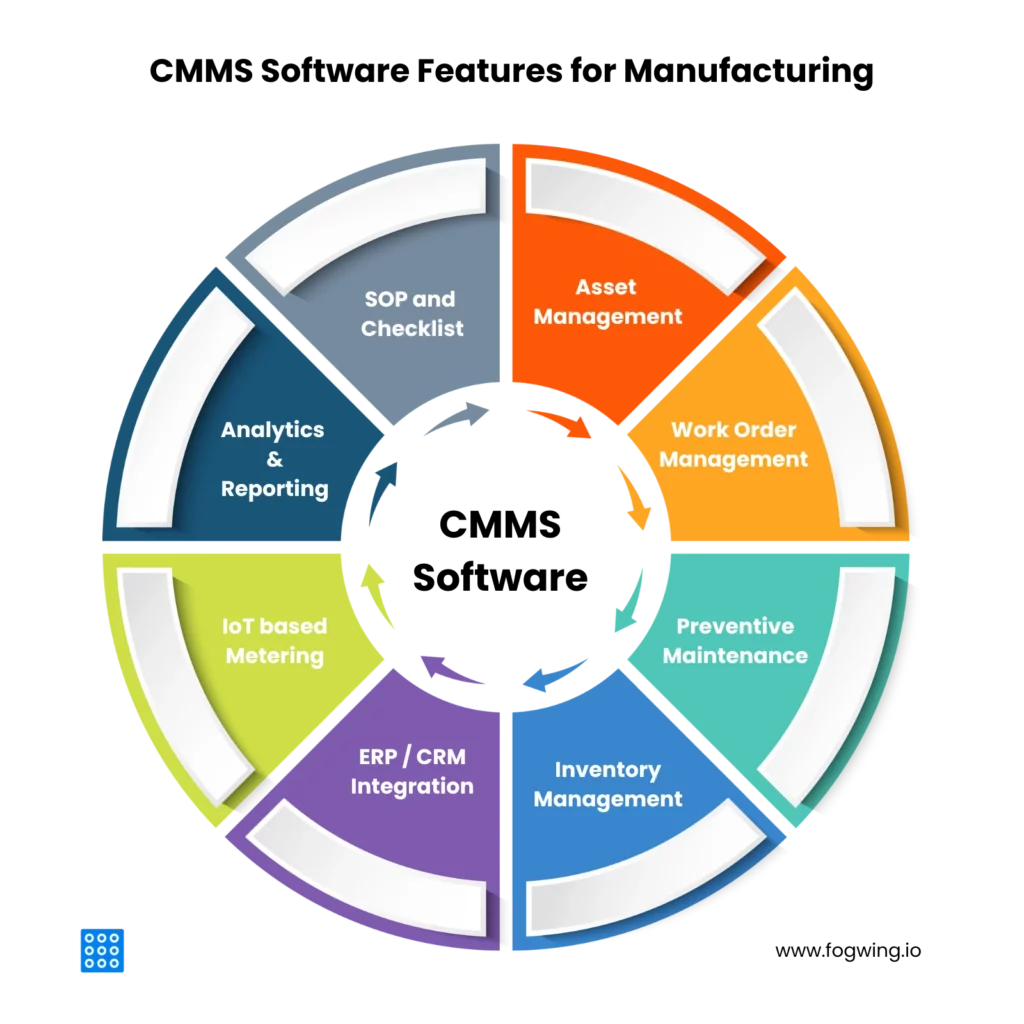

Features of CMMS Software – What to look for?

When selecting a Computerized Maintenance Management System for manufacturing, ensuring the system offers features that streamline operations, enhance productivity, and minimize downtime is essential.

Below are the key features to prioritize:

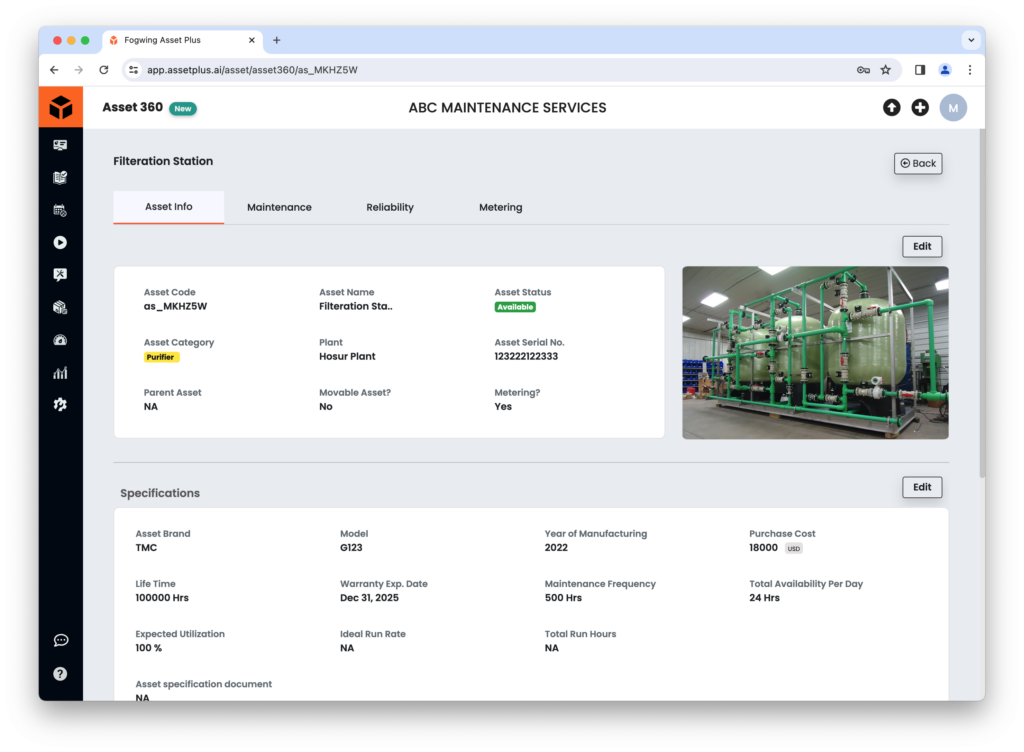

1. Asset Management

A CMMS for manufacturing should provide efficient tools for tracking machinery, equipment, and tools. Look for features that:

- Monitor asset performance to detect inefficiencies: CMMS’s standout feature is its asset monitoring module. This feature leverages complete advanced analytics data regarding the asset to monitor real-time asset conditions.

- Schedule preventive maintenance to avoid unexpected breakdowns: CMMS simplifies preventive maintenance with automated scheduling and real-time alerts. Its advanced tools help manufacturers reduce unexpected breakdowns, optimize asset performance, and ensure smoother, more reliable operations.

- Record detailed asset histories: For informed decision-making and compliance with regulations, CMMS for manufacturing allows you to record and access detailed asset histories, including maintenance logs, performance data, and repair records.

- It ensures informed decision-making, compliance, and better planning for asset lifecycle management.

2. Work Order Management

A streamlined work order process is critical for smooth maintenance operations. A robust CMMS allows you to create, assign, track, and close asset maintenance work orders efficiently, ensuring all tasks are timely.

CMMS offers a streamlined work order management process, enabling. Its intuitive interface ensures that work orders are prioritized, detailed, and assigned to the right technicians, reducing delays and miscommunication.

Real-time updates and notifications keep your team informed, ensuring timely task completion with comprehensive tracking and reporting.

CMMS Software for manufacturing helps manufacturers improve task efficiency, reduce downtime, and maintain a smooth workflow, ultimately driving operational excellence and reliability in maintenance operations.

3. Preventive Maintenance Scheduling

Proactive maintenance reduces unplanned downtime and extends the life of your assets. Your CMMS should include:

- Automated scheduling of maintenance tasks: CMMS simplifies maintenance management with its automated scheduling feature. It allows you to set recurring maintenance tasks, ensuring they are planned and executed on time.

- Automated reminders and notifications help reduce human error, minimize downtime, and keep assets running efficiently.

- Alerts and notifications to ensure no task is missed: CMMS’s robust alerts and notification system ensures no maintenance task is overlooked.

- It sends real-time updates to your team about upcoming, overdue, or critical tasks, promoting timely action and preventing unnecessary downtime.

4. Checklist or Procedure Enforcement

Checklist or procedure enforcement plays a crucial role in enhancing maintenance efficiency by ensuring standardized and consistent execution of maintenance tasks.

By following predefined steps, maintenance teams can systematically inspect, service, and repair equipment, reducing the likelihood of errors or missed tasks.

This structured approach helps maintain asset reliability, improve safety compliance, and extend equipment lifespan.

Additionally, digital checklists within advanced CMMS software enable real-time tracking, verification, and documentation of completed tasks, promoting accountability and audit readiness. With enforced procedures, organizations can optimize resource allocation, minimize unplanned downtime, and achieve operational excellence.

5. Inventory Management

Managing spare parts minimizes delays during maintenance. A good CMMS Software for manufacturing tracks inventory levels alerts you when stock is low, and helps reorder parts to avoid shortages. Many CMMS offers a comprehensive inventory management feature that helps track spare parts, tools, and materials in real time.

It provides insights into stock levels, ensuring you always have the necessary components. The system automatically generates alerts for low stock, facilitating timely reordering and minimizing delays in maintenance tasks.

By optimizing inventory management, CMMS reduces the risk of excess inventory, lowers storage costs, and ensures smooth operations without unexpected shortages.

6. Integration Capabilities

Choose a CMMS Software for manufacturing that integrates seamlessly with other systems, such as ERP tools, Internet of Things (IoT) platforms, or Manufacturing Execution Systems (MES). CMMS Integration enables real-time data sharing and holistic operational insights.

7. IoT Metering for Real-Time Monitoring

Fogwing CMMS integrates IoT-enabled metering to monitor critical asset parameters in real time. This enables maintenance teams to capture performance data, track energy consumption, and detect anomalies before they lead to failures, enhancing predictive maintenance strategies.

8. Reporting and Analytics

Comprehensive reporting and analytics are essential for tracking maintenance trends, evaluating asset performance, and optimizing resource allocation. These tools empower data-driven decisions to improve efficiency and reduce costs.

Selecting a CMMS with these features, such as CMMS, ensures a solution tailored to manufacturing needs. CMMS combines robust asset tracking, proactive maintenance tools, and advanced analytics to enhance productivity and support long-term success.

Cloud-based CMMS vs. On-Premise CMMS

When choosing a CMMS Software for manufacturing, you must consider your organization’s needs and decide between cloud-based and on-premises solutions.

Cloud-based CMMS offers several advantages, including remote access from anywhere, automatic software updates, and easy scalability. You don’t need to worry about hardware maintenance with a cloud-based system, as the provider hosts the software.

The cloud-based CMMS is ideal for businesses with multiple locations or a mobile workforce, offering flexibility and cost savings.

On-premises CMMS, on the other hand, provides complete control over your system and data. It’s typically hosted on your organization’s servers and requires maintenance from an in-house IT team.

This option may be more suitable for associations with strict data security needs or those who prefer to keep all operations within their network.

Before deciding on the CMMS Software for manufacturing, evaluate your existing IT infrastructure, security needs, and growth plans. Each option has its strengths, so you can choose based on your operational priorities.

How do we evaluate CMMS Costs and Pricing?

When evaluating a CMMS, consider all associated costs, including initial setup, implementation, subscription or licensing fees, and ongoing training and support.

While it’s compelling to concentrate solely on price, prioritize value instead. A slightly higher investment in a feature-rich CMMS can lead to robust long-term savings through improved asset performance, reduced downtime, and enhanced productivity.

Consider the overall ROI, including operational efficiency gains and cost reductions over time, rather than just the upfront costs while selecting CMMS for manufacturing. This thoughtful approach ensures you choose a system that offers immediate and lasting value.

Demo and Trial Periods with CMMS

Many CMMS software vendors, including Fogwing CMMS, offer free demos or trial periods to give you a firsthand experience of their system. During this time, take advantage of the opportunity to:

- Test the system’s features and usability: Explore CMMS’s user-friendly interface, advanced analytics, and mobile access to see how well it meets your needs.

- Get feedback from your maintenance team: Involve your technicians in the trial period to ensure they find the system intuitive and effective in improving their workflows.

- Assess alignment with your workflows: Evaluate how well CMMS integrates with your existing processes, from asset management to work order tracking.

By utilizing the demo or trial period, you can make a more informed decision about whether CMMS is the right solution for your manufacturing needs.

Common Challenges in CMMS Implementation

The CMMS software providers might offer many advantages when selecting a CMMS for manufacturing. The implementation process can present some challenges. Below are some common hurdles and how to overcome them:

Resistance to Change:

Employees may hesitate to adopt a new system, fearing disruptions to their routine. To overcome this:

- Comprehensive Training: CMMS software like Fogwing CMMS provides detailed training sessions and user-friendly resources to ensure a smooth transition for your team.

- Highlighting Benefits: Emphasize how CMMS software’s features, like automated maintenance scheduling and advanced analytics, will reduce downtime and improve productivity.

Data Migration:

Transferring data from legacy systems can be complex and time-consuming. Fogwing CMMS for manufacturing works closely with your team to ensure a seamless data migration process and minimize disruptions.

CMMS Customization Issues:

Not all CMMS systems fit your existing workflows out of the box. However, some of the CMMS allows you to customize the system without changing the process best practices to match your unique operational needs, ensuring a better fit and smoother implementation.

Addressing these common challenges with CMMS can help you enjoy a seamless, efficient, and productive transition to a more effective maintenance management system.

Why Fogwing CMMS is a Better Fit for Manufacturing Businesses

In the dynamic and demanding landscape of manufacturing, efficient asset and maintenance management are essential for ensuring uninterrupted production and operational excellence. Fogwing CMMS stands out as the ideal solution tailored specifically to meet the diverse and complex needs of manufacturing businesses. Here’s why Fogwing CMMS is the better fit:

1. Specialized Plant Shift Configurations

Manufacturing plants often operate around the clock with multiple shifts. Fogwing CMMS enables precise scheduling and maintenance activities tailored to plant shift configurations, ensuring minimal disruptions and enhanced operational efficiency.

2. Service Level Agreement (SLA) Monitoring

With SLA tracking capabilities, Fogwing CMMS helps manufacturers set and monitor maintenance service agreements to ensure timely completion of work orders, reducing production delays and improving asset reliability.

3. Multi-Site and Asset Hierarchy Management

Managing multiple manufacturing facilities becomes seamless with Fogwing CMMS. It allows businesses to oversee maintenance activities across multiple sites while organizing assets into hierarchical structures for better visibility and control.

4. AMC and CMC Management

Efficient management of Annual Maintenance Contracts (AMC) and Comprehensive Maintenance Contracts (CMC) is critical for manufacturers. Fogwing CMMS simplifies contract tracking, vendor engagements, and compliance, ensuring smoother maintenance operations.

5. Capitalization and Cost Tracking

Fogwing CMMS supports asset capitalization, enabling manufacturers to track maintenance expenses and allocate budgets more effectively. This helps optimize costs and improve financial decision-making.

6. Preventive and Predictive Maintenance Support

Fogwing CMMS offers robust preventive and AI-powered predictive maintenance capabilities. By analyzing real-time asset data, it helps predict potential failures, schedule maintenance proactively, and minimize unplanned downtimes.

7. Vendor and Third-Party Supplier Management

Managing multiple vendors and suppliers can be challenging for manufacturing businesses. Fogwing CMMS streamlines vendor interactions, contract management, and performance tracking, fostering better collaboration and accountability.

8. Parts and Inventory Management

Efficient spare parts management is critical for minimizing repair times. Fogwing CMMS provides real-time inventory tracking and reordering alerts to ensure essential parts are always available when needed.

9. AI-Based Root Cause Analysis

Fogwing CMMS harnesses the power of Spike AI Assistant to identify and analyze the root causes of equipment failures. This empowers maintenance teams to implement corrective actions and enhance asset reliability over time.

10. Compliance Reporting

For manufacturers aiming to maintain industry certifications, Fogwing CMMS offers comprehensive reporting features that support compliance with ISO and other regulatory standards, making audits and documentation management seamless.

Fogwing CMMS delivers an all-encompassing solution tailored to the unique challenges of manufacturing operations. From asset hierarchy management to AI-driven maintenance insights, it empowers manufacturers to optimize their maintenance processes, reduce operational costs, and ensure sustained production excellence.

Conclusion

Selecting the right CMMS for manufacturing operations is a strategic decision that can impact your efficiency and bottom line. You can choose a system that aligns with your goals by focusing on your needs, evaluating key features, and prioritizing user-friendliness.

Fogwing CMMS, with its robust features, intuitive interface, and tailored solutions, is an excellent choice for manufacturers looking to streamline maintenance operations and drive operational success.

Remember to use demos and trial periods to ensure the system aligns with your workflows and effectively engages your team.