Learning Center EAM What Is EAM in Maintenance? In today’s industrial landscape, Enterprise Asset Management (EAM) is pivotal for organizations aiming to maximize the value and performance of their physical

Learning Center

Asset Monitoring

Achieving World-Class Planned Maintenance Percentage (PMP)

Planned Maintenance Percentage (PMP)

In today’s competitive landscape, organizations recognize that effective maintenance strategies are crucial for operational excellence. A high Planned Maintenance Percentage (PMP) is a hallmark of world-class maintenance management. This blog outlines the steps to achieve and maintain a world-class PMP, ensuring optimal equipment reliability and performance.

Responsibilities of Maintenance Mechanics

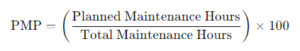

PMP is the ratio of planned maintenance activities to total maintenance activities, expressed as a percentage. A higher PMP indicates that more maintenance tasks are scheduled and executed proactively, minimizing unexpected breakdowns and maximizing equipment uptime. The formula for calculating PMP is:

Steps to Achieve World-Class PMP

- Develop a Comprehensive Maintenance Strategy: A successful maintenance strategy should incorporate various aspects, including:

- Preventive Maintenance (PM): Regularly scheduled maintenance tasks to prevent equipment failure.

- Predictive Maintenance (PdM): Using data analytics and condition monitoring to predict when maintenance should be performed.

- Reliability-Centered Maintenance (RCM): A systematic approach to ensure that systems continue to do what their users require in their present operating context.

- Utilize Technology and Data Analytics: Leverage modern technologies like Computerized Maintenance Management Systems (CMMS) to:

- Schedule and track maintenance activities.

- Monitor equipment health through IoT devices.

- Analyze data to identify trends and areas for improvement.

Implementing a robust data analytics framework enables informed decision-making and prioritization of maintenance tasks.

- Train and Empower Your Workforce: A skilled workforce is essential for effective maintenance practices. Invest in training programs to enhance employees’ technical skills and knowledge of best practices. Encourage a culture of ownership where maintenance staff are proactive in identifying issues and suggesting improvements.

- Standardize Maintenance Procedures: Creating standard operating procedures (SOPs) for maintenance tasks helps ensure consistency and quality. This standardization can reduce errors and improve efficiency. Regularly review and update these procedures based on feedback and lessons learned from past maintenance activities.

- Optimize Spare Parts Management: A well-organized spare parts inventory ensures that necessary components are available when needed. Implement just-in-time inventory practices to reduce carrying costs while ensuring quick access to critical parts. Maintain relationships with reliable suppliers for timely deliveries.

- Foster a Continuous Improvement Culture: Encourage a mindset of continuous improvement within the maintenance team. Use methodologies such as Lean and Six Sigma to identify waste, streamline processes, and enhance overall efficiency. Regularly review maintenance metrics and adjust strategies based on performance data.

- Set Realistic Goals and Metrics: Establish clear, achievable goals for your PMP and monitor progress regularly. Use key performance indicators (KPIs) to measure the effectiveness of your maintenance strategy. Common KPIs include:

- Overall Equipment Effectiveness (OEE)

- Mean Time Between Failures (MTBF)

- Mean Time to Repair (MTTR)

- Engage Leadership Support: Securing buy-in from leadership is vital for successful maintenance initiatives. Communicate the value of maintenance improvements in terms of cost savings, increased productivity, and enhanced safety. Regularly report on progress and outcomes to maintain engagement and support.

- Implement a Feedback Loop: Create a system for collecting feedback from maintenance personnel and other stakeholders. This feedback can provide valuable insights into areas for improvement, helping to refine processes and enhance the overall maintenance strategy.

Conclusion

Achieving a world-class Planned Maintenance Percentage requires a strategic approach, combining technology, skilled personnel, and continuous improvement practices. By focusing on these key areas, organizations can enhance their maintenance capabilities, leading to reduced downtime, improved equipment reliability, and ultimately, greater operational success. Investing in a robust maintenance program not only pays off in efficiency but also positions your organization as a leader in your industry.

Get our newsletters delivered directly to your inbox.

By submitting ,you agree to Fogwing Terms of Service. Your personal data will be processed in accordance with Fogwing Privacy Policy.

Read more articles...

Learning Center Maintenance Management What is PM and CM in maintenance? In maintenance, PM stands for Preventive Maintenance — a proactive approach to preventing failure through regular, scheduled care. CM

Learning Center Asset Monitoring Industry 4.0 vs Industry 3.0: A Comparative Journey of Industrial Evolution Industry 4.0 vs Industry 3.0 Industries have undergone transformative phases over the years, each marked