In the rapid digital world, maintenance and operations management businesses are increasingly deploying digital tools to streamline operational processes, reduce downtime, and maximize operational efficiency.

However, when CIOs and IT leaders explore software solutions to meet business demands, they often encounter a variety of providers offering CMMS (Computerized Maintenance Management Software), FMS (Facility Management Software), and FSM (Field Service Management Software).. This CMMS vs FMS vs FSM comparison can sometimes lead to confusion

While these solutions share overlapping features and functions, each shows distinct objectives, terminologies, and industry use cases.

This blog dives into the functional differences, terminology differences, and industry-specific applications of these three categories, and why a unified platform like Fogwing is the future of operational excellence.

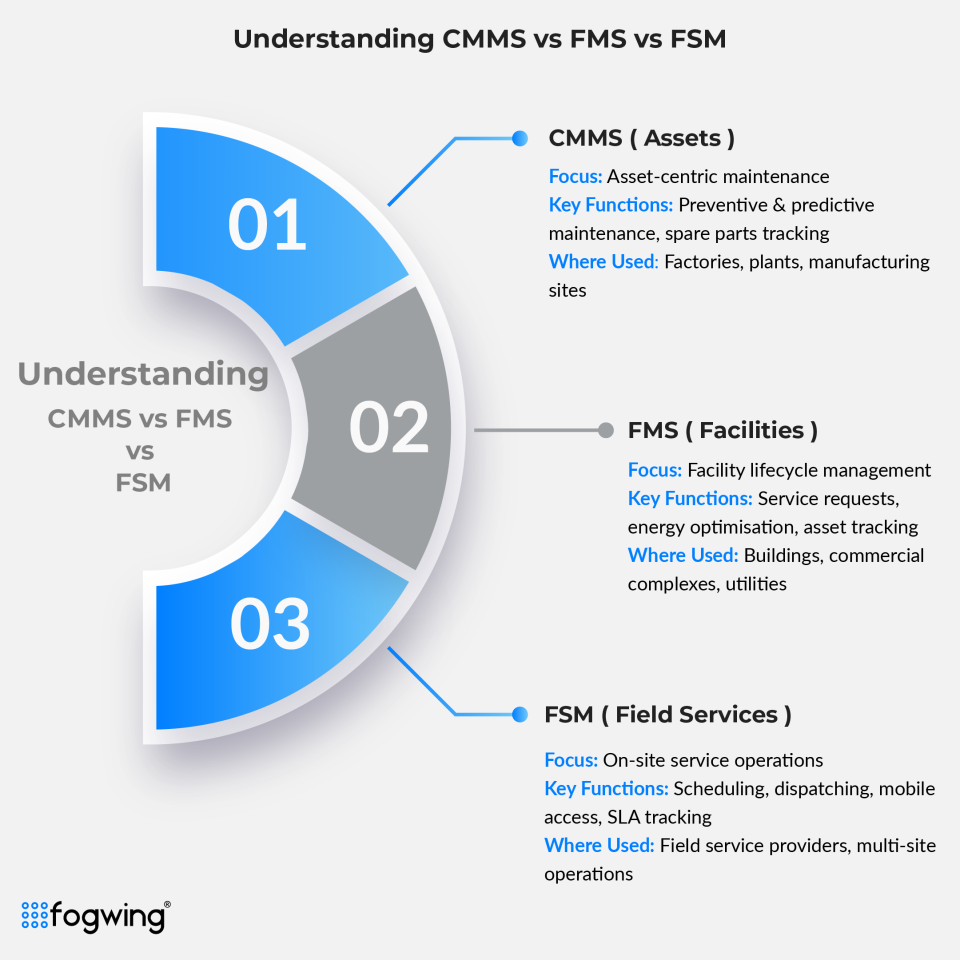

Understanding CMMS vs FMS vs FSM

First, let us understand the core meaning of these three systems.

What is CMMS?

A CMMS (Computerized Maintenance Management System) is primarily designed for asset-centric maintenance operations. In general, CMMS software offers features and functions to manage asset information, schedule preventive maintenance, automate predictive maintenance, and perform corrective or on-demand maintenance activities.

CMMS software helps to maintain an asset database, records maintenance history, tracks spare parts, and ensures compliance with reliability standards.

What is Facility Management Software?

The FMS (Facility Management Software) helps business organizations manage the entire lifecycle of facility maintenance, service request and fulfillment, equipment maintenance, asset tracking, energy optimization, and environmental compliance.

The primary scope is to ensure larger commercial buildings, utility centers, and commercial workplaces operate efficiently while enhancing the experience of occupants.

What is Field Service Management Software?

FSM (Field Service Management) software is combines the asset maintenance and facility management features together with on-site services. Therefore, FSM is predominantly helpful for businesses that provide operational services across regions and locations where they deploy field engineers to address various service requests.

It supports service scheduling, dispatching, route optimization, customer contracts, SLA tracking, and mobile access for field technicians.

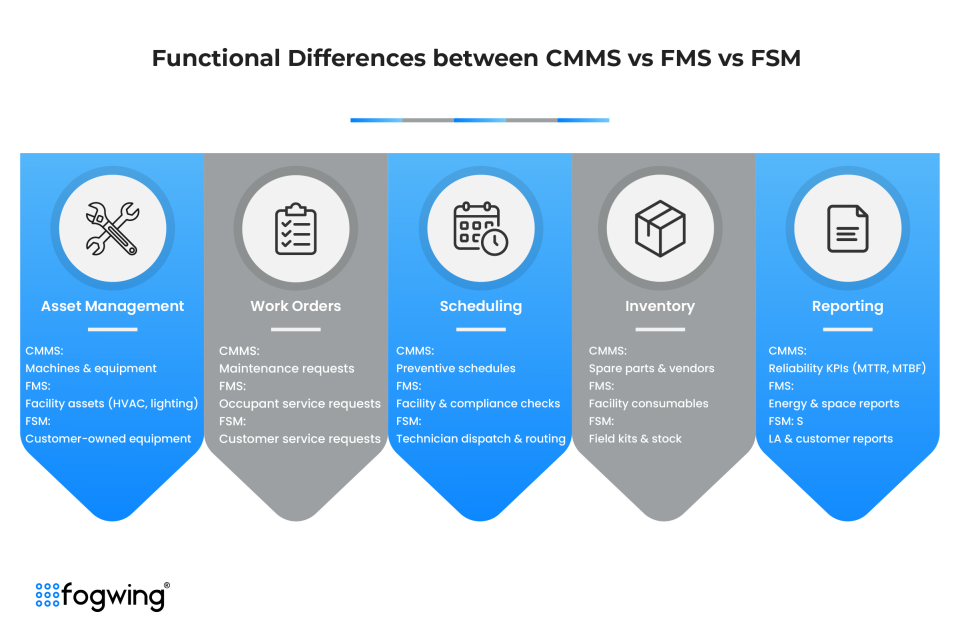

Functional Differences between CMMS vs FMS vs FSM

While all three systems manage work orders, assets, and service requests, the depth and focus vary significantly: This section breaks down the functional scope in the CMMS vs FMS vs FSM debate.

1. Asset and Equipment Management

- CMMS: Tracks machines, production lines, and industrial equipment. Provides preventive and predictive maintenance schedules, condition monitoring, and asset lifecycle tracking.

- Facility Management: Focuses on facility-related assets such as HVAC systems, lighting, elevators, and utilities. Asset management here is tied to building comfort, compliance, and safety.

- Field Service Management: Manages customer-owned equipment or installations. Focus lies in asset servicing, warranty tracking, and service contract renewals.

2. Work Order and Service Requests

- CMMS: Work orders are raised for preventive maintenance, breakdowns, or inspections. They are tied directly to equipment reliability.

- Facility Management: Service requests can come from occupants (example: HVAC not working, space relocation, or compliance inspections). Work orders are often linked to facilities, safety, and comfort.

- FSM: Work orders are primarily customer-driven (repairs, installations, or warranty services). Includes advanced features like routing and dispatching to technicians.

3. Scheduling and Dispatching

- CMMS: Focus on scheduling preventive maintenance based on calendar, usage hours, or IoT data.

- Facility Management: Scheduling is broader—room bookings, cleaning schedules, utility checks, compliance audits.

- FSM: Scheduling involves workforce allocation, technician routing, GPS tracking, and customer appointment booking.

4. Spare Parts and Inventory Management

- CMMS: Deep inventory tracking for spare parts, consumables, and vendor management. Critical to reduce downtime.

- Facility Management: Inventory includes consumables like cleaning supplies, safety equipment, or replacement parts for facility systems.

- FSM: Inventory is tied to field kits, replacement parts carried by technicians, and stock replenishment across warehouses.

5. Reporting and Analytics

- CMMS: Reliability metrics such as MTTR (Mean Time to Repair), MTBF (Mean Time Between Failures), downtime analysis, and maintenance costs.

- Facility Management: Reports on energy consumption, space utilization, occupant satisfaction, and compliance adherence.

- FSM: Reports on SLA compliance, first-time fix rate, customer satisfaction, and workforce productivity.

Terminology Differences between CMMS vs FMS vs FSM

Each system uses its own operational language. Here’s how the key terms differ across CMMS vs FMS vs FSM systems:

| Category | CMMS | FMS | FSM |

|---|---|---|---|

| Work Orders / Requests | Work Orders, Preventive Maintenance, Breakdown Maintenance | Service Requests, Facility Tickets, Compliance Tasks | Customer Work Orders, Service Calls, Job Tickets |

| Asset Management | Equipment, Machines, Asset Lifecycle, MTTR, MTBF | Facility Assets, HVAC, Utilities, Space Assets | Customer Assets, Installed Base, Warranty Assets |

| Scheduling | Preventive Maintenance Schedules, Predictive Maintenance Triggers | Cleaning Schedules, Inspection Schedules, Room Bookings | Technician Scheduling, Dispatching, Route Optimization |

| Performance Tracking | Downtime, Uptime, Reliability, Failure Analysis | Energy Efficiency, Occupant Satisfaction, Compliance Reports | SLA Compliance, First-Time Fix Rate, Customer Satisfaction |

| Inventory & Resources | Spare Parts, Consumables, Vendor Management | Facility Supplies, Safety Stock, Compliance Materials | Technician Parts Kits, Field Stock, Replenishment |

| User Roles | Maintenance Technicians, Reliability Engineers, Asset Managers | Facility Managers, EHS Officers, Building Operators | Field Technicians, Dispatch Coordinators, Service Managers |

Understanding these differences helps avoid mismatches when evaluating solutions. For example, a CMMS vendor may not fully address space planning needs, while an FSM solution may lack predictive maintenance analytics.

Industry-Specific Differences between CMMS vs FMS vs FSM

The industries best suited for each software differ greatly:

CMMS Industries

- Manufacturing → Keep production equipment operational and reduce downtime.

- Energy & Utilities → Manage critical assets like turbines, generators, and substations.

- Automotive → Ensure reliability of assembly line machines.

- Pharmaceuticals → Maintain GMP compliance with strict asset maintenance.

Facility Management Industries

- Healthcare → Hospitals need facility systems to run reliably for patient safety.

- Airports → Space utilization, utilities, and safety systems must operate 24/7.

- Retail → Maintain store environments and energy efficiency.

- Education → Campus-wide facility management for safety, compliance, and comfort.

Field Service Management Industries

- HVAC & Plumbing → Service scheduling, dispatch, and repair history tracking.

- Telecom → Manage field technician operations for installations and repairs.

- Utilities → Meter servicing, outage management, and customer repairs.

- Equipment Repair Services → Warranty and after-sales service for industrial and consumer products.

Why Organizations Struggle to decide the right software?

Many businesses, especially large enterprises, often end up implementing separate software for CMMS, Facility Management, and Field Service Management. The CMMS vs FMS vs FSM dilemma often leads to silos, higher costs, and reduced efficiency.

Data silos emerge when asset, facility, and service data are stored in different platforms, making it difficult to gain a unified view of operations. Reporting becomes inconsistent, with each system tracking its own KPIs, slowing down strategic decision-making.

Managing multiple vendors also drives higher IT costs and complexity, from software licenses to integrations.

Collaboration suffers too—maintenance, facility, and field teams cannot easily share information, causing delays in issue resolution. Most importantly, organizations lose agility. Real-time events like machine failures, compliance issues, or customer service requests require quick cross-functional responses, which separate systems can’t provide.

Over time, this fragmentation prevents businesses from leveraging predictive insights and limits efficiency. That’s why unified platforms are becoming the smarter choice for modern operations.

In short, while separate systems may appear to serve specialized needs, they create barriers to efficiency, cost control, and strategic growth. This is why many forward-thinking organizations are moving toward unified platforms that combine the capabilities of CMMS, Facility Management, and Field Service Management under one roof.

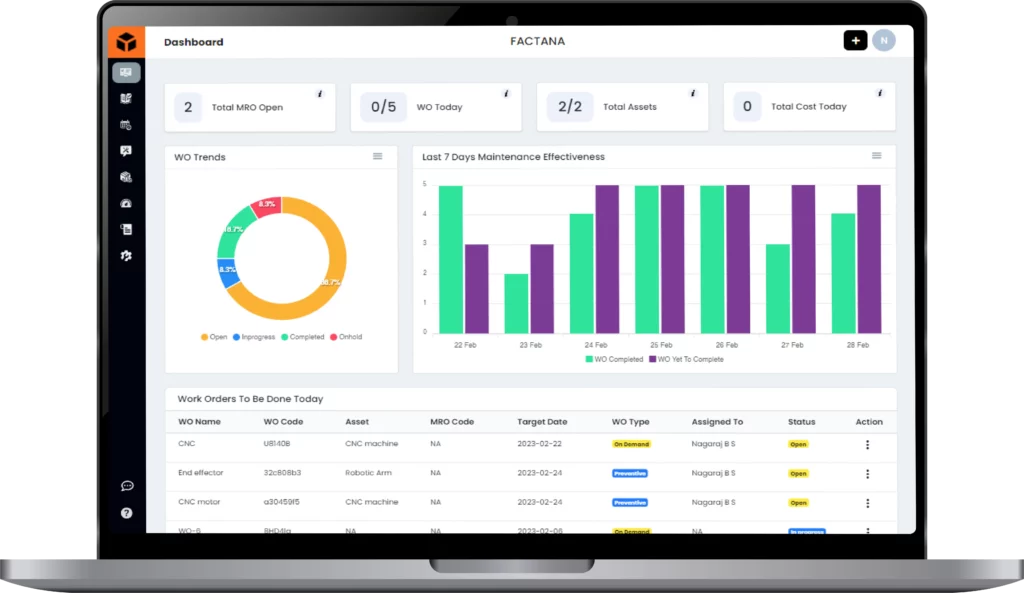

Fogwing: One Platform, Three Capabilities

This is where Fogwing Operations Management Platform stands apart. It combines the power of CMMS, Facility Management, and Field Service Management into one unified ecosystem.

How Fogwing Solves the Problem?

- Unified Asset Database: Manage industrial equipment, facility assets, and customer installations in one platform.

- Work Order Flexibility: Handle preventive maintenance, occupant service requests, and field service dispatch from the same system.

- Mobile-First Field Services: Equip technicians with mobile apps for real-time updates, customer signatures, and GPS tracking.

- Predictive Analytics: AI-driven insights prevent breakdowns, reduce downtime, and optimize resource utilization.

- Scalable for All Industries: Manufacturing plants, hospitals, airports, and field service companies can use Fogwing without switching platforms.

By consolidating these three capabilities, Fogwing reduces complexity, lowers costs, and ensures organizations have 360-degree visibility into all operations.

Fogwing eliminates the confusion of choosing between CMMS vs FMS vs FSM, offering a single platform for complete operational excellence.

Conclusion

Choosing the right operational software depends on your organization’s priorities—whether it’s maintaining equipment, managing facilities, or coordinating field services. While CMMS, Facility Management, and Field Service Management systems each bring unique strengths, running them separately often leads to data silos, inefficiencies, and higher costs.

The future lies in integration. By unifying these capabilities on a single platform, businesses can achieve complete visibility, faster collaboration, and smarter decision-making powered by data.

This is where Fogwing Asset Operations Management Platform stands apart. It combines the depth of CMMS, the breadth of Facility Management, and the mobility of Field Service Management into one ecosystem—augmented with AI-driven insights and IoT connectivity. With Fogwing, organizations gain not just three solutions in one, but a scalable, future-ready platform designed to lower costs, boost uptime, and deliver operational excellence across industries.

If your goal is to eliminate complexity and drive efficiency, the answer is clear: one platform, endless possibilities with Fogwing.

Frequently Asked Questions (FAQs)

1. What is the main difference between CMMS and Facility Management Software?

CMMS focuses on asset reliability and maintenance, while Facility Management software focuses on managing buildings, utilities, and occupant requests.

2. How does Field Service Management differ from CMMS?

FSM is customer-focused, enabling field technicians to manage service requests and contracts, while CMMS is internally focused on asset upkeep.

3. Can one platform handle CMMS, Facility, and Field Service needs?

Yes. Fogwing provides an integrated solution combining maintenance, facility operations, and field service management.

4. Which industries need CMMS the most?

Manufacturing, energy, oil & gas, automotive, and pharmaceuticals heavily rely on CMMS.

5. Why is Fogwing different from traditional CMMS software?

Fogwing goes beyond CMMS—it integrates facility management and field service capabilities, powered by AI and IoT insights, to provide a unified operations management platform.